Projects and Features

SSDA 2023 National Finalists

Farringdon Crossrail Station, East & West Ticket Halls

FACT FILE

Architect: Aedas

Structural engineer: AECOM

Steelwork contractor: Bourne Group Ltd

Main contractor: BAM Ferrovial Kier JV

Client: TfL (Crossrail)

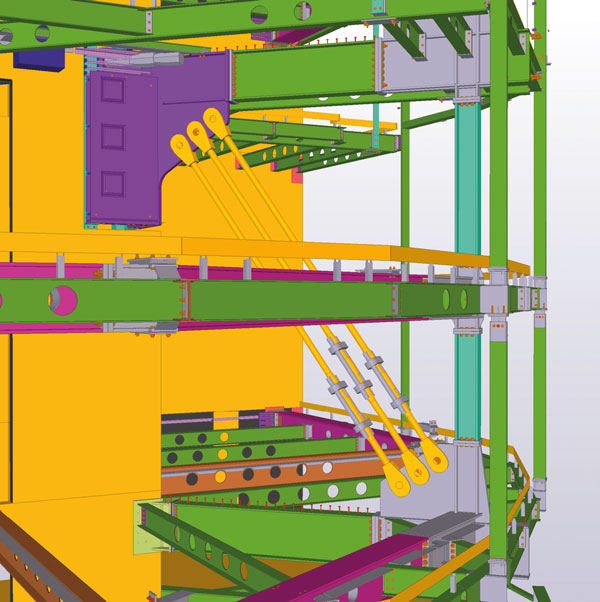

Structural steelwork played an important role in the construction of the Crossrail Elizabeth line in London. An example of this work are the two tickets halls at Farringdon station.

The western ticket hall is approximately 75m-long x 62m-wide and steelwork commences at Level -1 and extends up to Level 3, which is formed by a series of 18.7m-high columns. The upper levels accommodate the large tunnel ventilation fans and other Crossrail plant rooms, administrative space and staff areas.

Creating a large open-plan area at upper ground floor, a series of steel trusses up to 21m-long and 4m-deep, form the cathedral-like Upper Apse ceiling and support a six-storey office block above.

The smaller eastern ticket hall is approximately 69m-long x 33m-wide and also provides an interchange with the London Underground platforms at nearby Barbican station. The design of the eastern ticket hall has used a series of raking columns to avoid loads being transferred to the shallow London Underground tunnel, which passes under its northern façade.

Church of Oak Distillery, Ballykelly, Co. Kildare

FACT FILE

Architect: ODOS Architects

Structural engineer: J.J. Campbell & Associates

Steelwork contractor: Steel & Roofing Systems

Main contractor: Ormonde Construction

Client: Oakmount

Dating back to the early 1800s, the long-established Church of Oak Distillery has been largely refurbished to create a visitor attraction with tasting rooms, a roof garden and an exhibition area.

The centrepiece of the scheme is the redeveloped Block C, where a two-storey steel-framed infill structure has been installed within retained walls and vertical steelwork, originally built in the 1930s.

The ground floor of the building accommodates the distillery processing and is a column-free space. Work is centred around a large pot still that has been incorporated through the suspended first and second floors. A glass floor at the uppermost level allows visitors to see the distillery below.

An elaborate steel roof structure, clad with weathering steel and incorporating elevated ventilation enclosures, tops the building.

A 3m-wide cantilevered external planter at first floor level meant that a significant 50-tonne load had to be transferred into each frame, which creates large horizontal shearing forces at both the roof and second floor levels. These two floorplates were designed to avoid any movement from the lateral shearing stresses created by the planter.

Dukes Meadows Footbridge, Chiswick

FACT FILE

Architect: Moxon Architects

Structural engineer: COWI (detailed design and construction engineering), Campbell Reith (concept design)

Main contractor: Knights Brown Construction Ltd

Client: London Borough of Hounslow

Dukes Meadows Footbridge is a new pedestrian bridge in Chiswick, west London, positioned beneath the existing Grade II listed Barnes Bridge. The low-carbon structure rejuvenates a previously disconnected stretch of the Thames Path, dramatically improving safety, access and pedestrian flow.

The steel structure is a ‘half through’ truss form with distinctive bracing members angled to maximise oblique views to the river. Estimates show innovation in structural arrangement, material specification and construction technique between design and completion enabled a 20 to 30% reduction in the footbridge’s overall carbon footprint compared to the client’s reference design.

The steelwork fabrication employed state-of-the-art digital 3D modelling techniques to inform the team of the complex geometry. This process employed double-curved SHS chords, RHS cross beams, bespoke fabricated diagonals and purlins, facetted steel boxes with openings for temporary works and electro-polished stainless steel parapets.

The delivery and installation of the main span beneath Barnes Bridge was carried out making full use of the tidal range of the Thames. The span was transported to site along the Thames on a specialist marine pontoon.

Arbor, Bankside Yards, London

FACT FILE

Architect: PLP Architecture

Structural engineer: AKT II

Steelwork contractor: Severfield

Main contractor: Multiplex Construction Europe Limited

Client: Native Land

Part of the first phase of Bankside Yards a development on London’s South Bank, Arbor is an 18-storey office block that combines high-spec office space and a surrounding public realm.

Levels one, two and three of the building are only partial floorplates that help to create Invicta Plaza, an open and covered area at the ground floor level that will serve as one of the district’s main gateways, along with and a triple-height reception, with a full-height atrium above.

The partial floorplates also help Arbor to span over part of the adjacent railway arches, with a series of four columns, punched through the Victorian structure and supporting part of the building’s eastern elevation.

These 20m-long columns weigh close to 22t each and had to be fabricated and brought to site in two pieces. The baseplates were welded to the lower halves and fixed to the pile caps, while the upper halves were passed through the arch openings and connected via a splice connection.

The JJ Mack Building, London

FACT FILE

Architect: Lifschutz Davidson Sandilands

Structural engineer: AKT II

Steelwork contractor: William Hare

Main contractor: Mace

Client: Helical plc

Located in the City of London, The JJ Mack Building is a 10-storey, steel-framed office block of 19,000m² that also accommodates ground floor retail space.

Sat on a complex site, the substructure interfaces directly with the 20m-deep excavations of Farringdon station’s Crossrail facilities and tunnels.

A steel-framed solution was chosen as it efficiently provided the desired long spans and special flexibility within the site’s irregular plan, minimised the foundation loadings and minimised disruption to the surrounding infrastructure and estate.

At the southern edge, a storey-high Vierendeel truss spans 15m and integrates with the façade mullions to create a dramatic entrance space opposite the forthcoming Museum of London development.

Through the upper levels, the massing transfers inwards with a series of cascading transfer beams to create three terraced amenity spaces overlooking the historic Smithfield Market buildings and the adjacent urban intersection.

A single core helps to maximise the uninterrupted internal floor area and an internal ‘light-scoop’ – a structural void that cuts through six storeys – provides generous daylighting.

M8 Footbridge, Sighthill, Glasgow

FACT FILE

Structural engineer: Jacobs

Steelwork contractor: Severfield

Main contractor: BAM Nuttall

Client: Glasgow City Council

Spanning the M8 motorway, a new footbridge forms a central element of the £250M Sighthill Transformational Regeneration Area (TRA), which offers affordable housing within walking distance of Strathclyde University, Queen Street Station and Glasgow’s most popular shopping locations

The bridge deck is part of a striking wider public realm project featuring 800 trees, 10,000 plants and a distinctive 210m-long southern approach with a ramp. To the north side, in Sighthill, the bridge arrives to a new public square which guides users up onto the hill or to the west to the canal basin amenities.

The bridge structure’s main span is formed by a 58m-long open-top steel box girder acting compositely with a reinforced concrete deck slab and required 420t of steelwork.

Weathering steel was said to be the natural choice for this structure, as it is widely used in the UK for both National Highways and Network Rail bridges, where minimal future maintenance is a key consideration.

The National Robotarium, Edinburgh

FACT FILE

Architect: Michael Laird Architects

Structural engineer: Tetra Tech

Steelwork contractor: BHC Ltd

Main contractor: Robertson

Client: Heriot-Watt University

Based at Heriot-Watt University’s Edinburgh campus, The National Robotarium is the largest and most advanced facility of its type in the UK and is a stand-out landmark building within the university campus.

The desired architectural vision for an industrial-looking interior has been created with exposed steel columns and beams throughout, while the exterior features a prominent double-skin glazed frontage, formed with a secondary lightweight steel frame.

The project is said to have suited the use of steel because of the long spans involved, and in order to achieve the architectural design that incorporates exposed services.

Overall, the building is approximately 75m-long × 45m-deep. The ground floor houses the main laboratory areas, situated around a full-height forum that sits in the centre of the structure.

Measuring 24m × 12m, the forum is a multi-purpose area, acting as a meeting point, auditorium, general break-out and circulation space. It is topped by a series of six triangular rooflights that allow natural daylight to penetrate into the building.