Projects and Features

It’s one small step into a BIM process

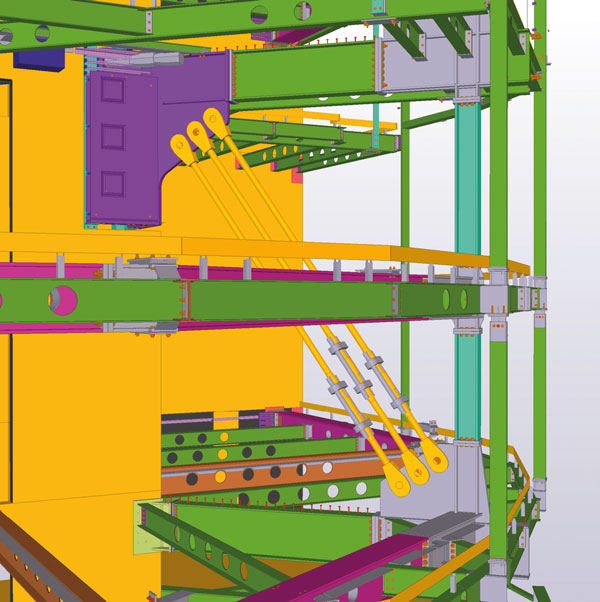

South Bank Tower, London. Modelled in Tekla Structures by Severfield plc

Just as the steel industry has developed massively over the last 20 years, so has Tekla software from Trimble. In fact, since 1966 Tekla has been providing leading solutions to the industry in order to help it work more efficiently. Over this time the modelling capabilities of its software has grown to meet the needs of the industry, which put both the constructional steelwork sector and Tekla users in a unique position to move from purely modelling to BIM.

Tekla Structures can create highly complex ‘as-will-be-built’ models for the structural elements of a building, which can be shared throughout the project’s design team to meet the UK Government mandate requirements for delivering Level 2 BIM.

Leading with experience

Duncan Reed, Digital Construction Process Manager at Trimble, says the constructional steelwork sector has an extensive track record in adopting technology and delivering projects using 3D processes. This was being done even before the term BIM came into being. So while the steel sector has been modelling projects for decades, this gives them the advantage of being just one small step away from implementing and leading the wider BIM processes within a project. “Strictly speaking, modelling alone isn’t BIM but sharing a model with the rest of the project is heading that way and a big advantage that can offer massive savings,” says Duncan. “BIM is a process that can, and will, bring efficiencies to companies’ existing processes – like those who already use models – in order to deliver projects quickly, competently and more reliably for clients.

“As such, the steel sector can take the chance to grab the opportunities that working digitally on projects presents by collaborating and sharing their expertise and experience in what is now seen as best practice. Every business can benefit from the adoption of BIM – no matter whereabouts in the construction chain they lie – they just first need to understand what that opportunity is for them.”

There are many benefits to adopting a BIM process, however one of the key drivers is driving out waste through collaboration, which ensures efficient working. Collaborative working is considered by many to be essential, particularly if design and construction teams are to consider the whole lifecycle of the construction process (1). By implementing BIM at the start of a project, it is possible for everyone in the design and construction team to collaborate and find the best solution available for a project. When it is done well, up-to-date and, more importantly, appropriate information is available, providing constructible information to the delivery team.

Duncan continues: “By taking a collaborative approach, the right information, in the right format delivered to the right people, at the right time – saves time and money spent on a project. The processes and procedures outlined in the recent UK BIM documentation encourage collaborative behaviours to help project teams to arrive at the right solution for their customers more quickly.

“Additionally, these values are also closely aligned to the UK Government’s Construction 2025, which sets out the long-term vision for how the industry and Government will work together to put Britain at the forefront of global construction.”

The 2025 report builds on some themes raised in the Latham and Egan reports, and the strategies set out in the 2011 Government Construction Strategy, which called for ‘a profound change in the relationship between public authorities and the construction industry’. It ambitiously proposed a 33% reduction in the whole-life cost of built assets, and 50% reduction in the overall time, from inception to completion, for the delivery of new build and refurbished assets.

The right information at the right time

“With this in mind, it has never been more important to view BIM as a great opportunity to reach these targets. Using a 3D model, like most of the steel industry is already doing, can save time and money on a project, but by sharing the model, details and data with other members of the project team for agreed purposes, will certainly help to reduce the time spent on a project and the costs of construction further,” says Duncan.

To maximise the efficiencies, each member of the project team must understand clearly what and how much information is required for each different stage of a project; too little information and risks may not be effectively managed – whilst too much information can lead to waste being added into the process.

This is where the BIM term Level of Definition (LOD) comes into play, and, Duncan says, potentially where the confusion begins too. Level of Definition is a UK BIM term defined in PAS 1192-2:2013 and is made up of two distinct requirements

3.30 Level of Definition

Collective term used for and including “level of model detail” and the “level of information detail”. NOTE: The “level of model detail” is the description of graphical content of models at each of the stages defined. The “level of model information” is the description of non-graphical content of models at each of the stages defined.

In essence, LOD refers to both the amount of graphical and non-graphical detail that may be required at different stages of a project, so a clear understanding of its meaning and purpose is important. This is considerably different to the term LOD that is used in the United States, in the document published by the American Institute of Architects. In that document, LOD means Level of Development, and principally deals with graphical detailing of models.

Aligning steel design to the Digital Plan of Works

“Fortunately it is very easy to determine whether a project is using the US or UK terminology,” Duncan says. “Here in the UK, Level of Definition is aligned to the Digital Plan of Work (DPoW), created by the UK BIM Task Group, which provides the UK construction industry with an eight-stage (zero – through to seven) design, construction and operation plan that can be used to define the information requirements throughout the whole life of an asset.”

In contrast, the US system principally defines just the stages of increased model development – as more detailed graphical representations – using the terms LOD100, LOD200, LOD300, LOD350, LOD400 and LOD500.

Using software that is capable of delivering a model to the required levels of definition and one that can be shared with all parties is therefore vital. Tekla software contains accurate, reliable and detailed information required for successful BIM and construction execution.

Duncan explains: “Here at Trimble we continue to support our customers and the industry to become more proficient in modelling and the BIM process. Modelling capabilities are advancing at a pace and, with the likes of machine control and robotic assembly now taking place, we are working alongside our customers continuously to push the boundaries and find new solutions to the complex and fast moving needs of the industry.”

“The development of each piece of Tekla software has had ‘the end’ in mind and so it very much aligns with the requirements of a BIM process. Our design and modelling software allows every party to do their job more efficiently and to share data seamlessly along the lifecycle of an asset, from early conceptual design through to assembly of a steel structure on site.”

Trimble Solutions (UK) is a headline sponsor of Steel for Life

Evolution of Tekla Structures for Steel

(1) Shelbourn, M., Bouchlaghem, N.M., Anumba, C. and Carrillo, P. (2007) ‘Planning and implementation of effective collaboration in construction projects’, Construction Innovation: Information, Process, Management, 7(4), pp. 357–377. doi: 10.1108/14714170710780101.