Projects and Features

Riverside refurbishment

A 1980s-built City of London office block is being redeveloped and enlarged with structural steelwork forming a south elevation that overlooks the River Thames and a new rooftop public amenity.

FACT FILE

Millennium Bridge House, London

Main client: Beltane Asset Management

Architect: Piercy & Company

Main contractor: ISG

Structural engineer: Heyne Tillett Steel

Steelwork contractor: Bourne Steel

Steel tonnage: 700t

The trend for refurbishing and enlarging existing city centre office blocks is continuing apace, as developers and the construction sector as a whole, view the process as a cost-effective alternative to demolishing a structure and starting again from scratch.

By retaining areas of a building and not knocking the entire building down, carbon savings can be made, while design techniques such as infilling atriums and adding new floors or extensions, can add valuable floorspace to a previously tired and out-dated structure.

Redeveloping and retaining existing buildings has proven to be ideal solution for the City of London, where large-scale demolition programmes can cause disruption to the many small, narrow and busy thoroughfares.

A current example of this trend is Millennium Bridge House, now known as One Millennium Bridge, which is situated on the north bank of the River Thames, a couple of hundred metres from St Paul’s Cathedral.

The 1980s-built concrete-framed commercial block is being transformed into a low carbon mixed-use scheme, which comprises the full regeneration of the five-storey building. A partial demolition programme has been undertaken, but crucially, just over 60% of the original structure has been retained.

Much of the retained structure is towards the northern part of the building, which spans over two road tunnels. These underpasses and the fact that the building sits on a slope, means the north elevation’s lowest level is second-floor at the southern elevation.

Although the main frame of the original building, as well as the majority of the new build, is concrete, structural steelwork is also playing an important role in the building’s redevelopment. Working on behalf of main contractor ISG, Bourne Steel has fabricated, supplied and erected 700t of steel for the project.

Perhaps the most visually pleasing steelwork element of the project is the new southern façade of the building, most of which overlooks the Thames. In this part of the scheme, the majority of the original structure has been stripped back to the area that spans the tunnels, and a new frame erected.

“The idea is for the new southern elevation to be expressed as its riverside location means it is the most visible part of the new building,” says Heyne Tillett Steel Structural Engineer Panos Logothetis. “The lowest two levels are formed with exposed steelwork, that supports four storeys of concrete-framed structure above.”

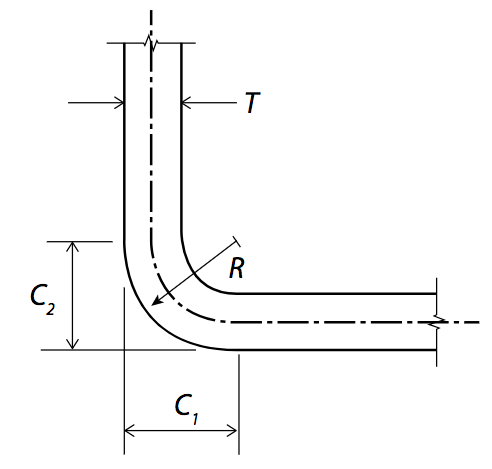

The front of the south elevation is created with a series of two-storey high feature upside-down L-shaped steel columns that also form a sheltered overhang along the riverside walkway, while supporting the building above.

The columns, which will remain exposed within the completed scheme, are painted dark red, which is said to be a nod to the area’s industrial heritage and the cranes that once adorned this part of the riverbank.

Fabricated from plate, the columns are all 6.5m-tall but their cantilevering upper part varies in length according to the location. The overhang’s depth, which has a maximum depth of 5m, varies along the building’s façade, as it curves around another riverside building.

“Typically, the cantilever is 3.5m-long on the majority of columns,” explains Bourne Steel Project Manager Duncan Wyatt. “They were all delivered to site as complete members with the upper part already welded in place, instead of bolted, to give the column the desired clean aesthetic appearance.”

The columns weigh up to 10t each and were installed using the site’s tower crane, although this was not the original plan, as ISG Construction Manager Magda Miazga explains: “We were going to use a mobile crane, positioned alongside the southern elevation, but the subsequent loads and the required propping would have impeded the progress of the basement fit-out.

There was no other location for the mobile, so we had to reconfigure the tower crane’s capacity, with the help of the manufacturer, so it could install the columns.”

The feature steel columns are also connected to another column that helps form a two-storey 20m-deep steel frame that connects back to the original concrete structure. Within the steel frame there is first-floor mezzanine level, formed with steel beams supporting a metal decked floor.

The overall development also includes an additional sixth floor and a rejuvenated rooftop. On completion, this space will offer a publicly accessible terrace and restaurant, maximising urban greening and external amenity space with new views over the Thames.

The rooftop is another interface where Bourne Steel has installed a significant amount of steelwork. Bolted to the structure’s roof, a steel grillage formed with fabricated beams, and covering almost half of the roof’s footprint, will support a restaurant pavilion.

The grillage acts as a transfer structure and the beams, which are up to 8m-long, follow the grid pattern of the concrete columns of the floors below. Springing off of the grillage, a series of 2.5m-high CHS columns, form the frame of the pavilion, which in turn support a timber glulam roof structure.

A steel and timber rooftop structure was chosen as it provided a lightweight solution that would not overload the existing columns below.

A third steelwork element installed by Bourne Steel is an external feature lift shaft, which is located in the northwest corner. The lift will provide direct public access to the rooftop amenities.

To aid the erection programme, the lift shaft was fabricated offsite as a series of fully-welded ladder frames, which were brought to site and bolted together to form the shaft. The initial steelwork to be erected for this feature element was the base, which measures 6m-long x 2.7m-wide, and was also delivered to site as a complete unit.

With space for materials storage at a premium around the project’s perimeter, the lift shaft steelwork was initially delivered to the roof of the building and then erected with the tower crane.

One Millennium Bridge is due to complete in 2023.