Projects and Features

Whisky distillery reborn

After a hiatus of nearly 30 years, steelwork is playing an important role in creating the facilities for production to restart at Falkirk’s Rosebank Distillery.

FACT FILE

Rosebank Distillery, Falkirk

Main client: Ian Macleod Distillers

Architect: Michael Laird Architects

Main contractor: ISG

Structural engineer: Blyth & Blyth

Steelwork contractor: Hescott Engineering

Steel tonnage: 400t

Whisky production has in recent times taken on a new lease of life and is now considered as a tourist and visitor attraction at many of Scotland’s leading distilleries.

Visitor centres, tasting rooms and an opportunity of a tour to see how the famous spirit is made, not only allows tourists a glimpse of an historic process, but also, and probably most importantly, encourages them to buy a bottle or two at the distillery shop.

An example of this trend can be found at the Rosebank Distillery in Falkirk, an historic site, originally built in the 1840s, but closed since 1993, which is being brought back to life with rebuilt tourist-friendly premises.

Set beside the Forth & Clyde canal, the distillery used this water source for its cooling process, a unique feature that will be resurrected once whisky production starts again at the end of the year.

However, before Ian Macleod Distillers, the new owners of the site, can begin producing their planned top-end whisky, a lot of work has to be completed.

Much of the original distillery has been demolished, as it was in too poor a condition to be restored and unsuitable for incorporation into the new design. These buildings have been replaced by new steel-framed structures, fronting the main road and creating a new entrance for the visitor centre and distillery.

The only exception along this elevation is a Nineteenth Century brick chimney, which is something of a local landmark and has been retained, with the new steel structure built around it.

It is a different story alongside the canal, where two Victorian buildings, a warehouse and the malt building, have been retained, refurbished and extended with new steel roofs and internal areas.

“To fulfil the architectural vision for the project, it was important to keep the canalside buildings,” says ISG Project Manager Michael Russell.

“However, new steelwork areas have created the necessary open-plan production and visitor spaces and helped the design combine new and old structures.”

In many areas throughout the scheme, steelwork connects to the retained buildings and even supports them in places. Meanwhile, in other areas, the new steel frame has to avoid existing structure.

Hescott Engineering Director Chris Scott says: “One of the biggest issues is that the new structure is positioned extremely close to the existing brick chimney, while we connect to the existing buildings in multiple locations across the site.

“Therefore, we initially carried out a laser scan of the site and integrated this into our model so that we could ensure that the new steel structure fitted within the confines of the plot and wrapped around existing structures without any clashes.”

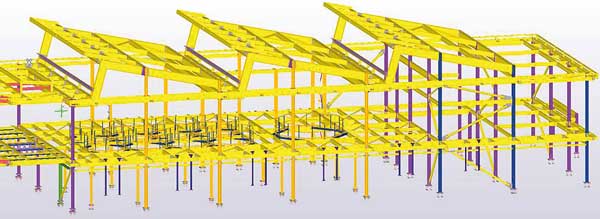

Measuring approximately 70m-long, the main new roadside steel structure is a two-storey building, topped with a feature saw-tooth roof, formed with a series of 4m × 15.5m welded cranked frames.

The main whisky distilling process will be undertaken within the entirety of the new steel-framed distillery building. The majority of the distillery equipment is housed at ground floor level. Steel mesh flooring at first floor level provides the distillery’s key working area, a smart ventilation solution, while acting as part of tour route for visitors, with dedicated marked walkways.

Large openings in the mesh flooring will accommodate stills and other large items of equipment that need to protrude from the ground floor up through the first floor.

Numerous large items of equipment are needed at the distillery and main contractor ISG has been constructing and sequencing the works around an ongoing fit-out programme.

Some of the largest items are three large copper stills, positioned in the new steel-framed structure and protruding through the largest openings in the first-floor mesh flooring.

Within the saw-tooth roof there are two demountable sections that initially allowed the stills (one demountable section for one still and the other for two slightly smaller vessels) to be installed into the completed steel frame. By simply unbolting the sections and removing them in one crane lift, they will also facilitate future maintenance work and the stills replacement every few years.

“Designing the feature roof would have been difficult in any other material other than steel, especially with the necessary demountable openings,” explains Blyth & Blyth Engineer Liam Colquhoun.

“As well as creating the new column-free areas, the steel columns and beams, the connections and some bracing elements are left exposed throughout the distillery, highlighting and accentuating the industrial heritage of the site.”

Overall, the site is wedge-shaped, with the new steel building meeting the largely retained structures at the southern end.

Connecting the two sides at the northern end and dissecting an inner courtyard is a wide, cobbled walkway known as ‘the street’. This steel-framed structure will feature extensive plate glass windows to further highlight and show the new Rosebank whisky making process.

The new steelwork is stabilised by cross bracings and the composite action of the flooring which, as well as steel mesh for the visitor centre, also includes metal decking, precast planks and restored timber flooring in some areas.

Within the retained structures, new steel roofs with long span rafters create the necessary column-free spaces for the maturation warehouse and the malt building. The latter has been extended northwards along the canalside elevation with new steelwork bays adjoining and connecting to the existing structure.

The rafters do not gain any support from the retained brickwork, but are instead supported on a new steel frame positioned inside of the existing walls.

These buildings will also accommodate first-floor offices and more visitor areas, including tasting rooms. For those willing to pay more for their visitor experience, VIP tasting suites will be located in a restored lock keeper’s cottage, which is positioned alongside the canal façade.

Summing up, Mr Russell says: “It is certainly a challenging project. We’ve got a main road in front, a canal at the back and a 160-year-old chimney right in the middle. And, we’ve got Historic Scotland involved because the buildings are listed. But it will all be worth it once whisky production starts up once again on this historic site later this year.”