Projects and Features

Steel creates signature support centre

The construction sector and its supply chain have joined together to support the latest Maggie’s centre in the grounds of the Royal Free Hospital in Hampstead, north London.

FACT FILE

Maggie’s Cancer Support Centre, Royal Free Hospital, London

Main client: Maggie’s

Architect: Studio Libeskind

Main contractor: Sir Robert McAlpine

Structural engineer: Expedition Engineering

Steelwork contractor: William Hare

Steel tonnage: 70t

Known for their individual architectural form as well as the outstanding care they provide to people with cancer, the latest Maggie’s cancer support centre features a bespoke raking curved façade, signature external fins and an enclosed rooftop garden and pavilion.

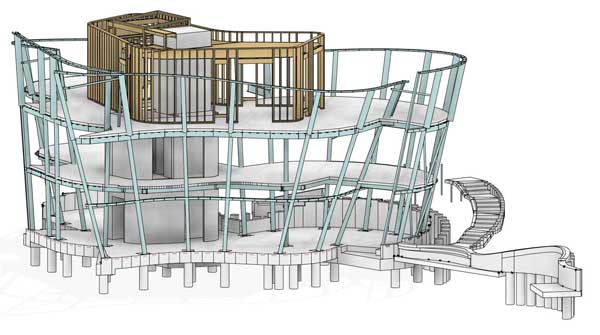

Being built at the Royal Free Hospital in north London, the two-storey building’s undulating form, which on plan has been likened to a fan being opened or even butterfly wings, has been formed with a steel frame.

After considering all framing solutions, steelwork was chosen by the project’s design team as the ideal material for the building’s complex shape and the requirement to have a flexible open-plan interior.

The building will contain approximately 400m² of floor space and accommodate a range of services including a large kitchen, small private spaces, a larger space for exercise and group meetings, and reflection spaces. Many of these spaces will be divided by moveable partitions, creating the desired flexibility.

The building is redeveloping a former car park site at the back of the hospital and is cut approximately 5m into a steep bank that separates the plot from neighbouring properties. The ground floor area is constrained and to maximise the available space the structure fans out at the upper levels creating more area for the first floor and the roof garden.

Working on behalf of Sir Robert McAlpine, who have been the main contractor for a number of Maggie’s projects, William Hare has fabricated and erected the steel for the project.

All of the project team have supported the scheme in different ways, and this has extended to the supply chain. Approximately two-thirds of the steelwork used on this project has been donated by ArcelorMittal free of charge.

ArcelorMittal Technical Manager Neil Tilley says: “We recognise the invaluable support Maggie’s give to patients and families in such worrying times, we’re very happy to support the great work they do.”

The steel sections were supplied from ArcelorMittal’s Differdange site in Luxembourg, which is an electric arc furnace (EAF) steelmaking plant, and is said to have saved approximately 90 tonnes of embodied carbon on this building.

The remaining one-third includes the main perimeter columns, which are Rectangular Hollow Sections (RHS). These members create the frame for the signature curving and raking façade, by leaning outwards by up to 35 degrees.

“The columns introduce a set of significant loadings as they try to pull out from the building. As the geometry is highly irregular and asymmetric, the building as a whole is being pulled and twisted, and these loads are taken back to the central core through the composite concrete deck system,” says Expedition Engineering Associate Structural Engineer James Parker.

“Therefore, the building design introduces lateral loads similar to that on a 12-storey tower of the same footprint, but with greater stability required.”

With only four internal columns – which are typically Circular Hollow Sections (CHS), chosen for their aesthetic value as they are the only steel members that will remain exposed – the majority of perimeter columns are connected directly to the building’s main centrally-positioned concrete core, creating spans of up to 10m.

“We worked closely with Expedition to detail the building extensively in three dimensions, as every beam-to-column connection is unique,” says William Hare Project Director Francisco Loureiro.

“An extensive amount of secondary bracketry had to be detailed to perfectly match the complex curved shape of the building, as it was important that no items such as bolts penetrated the façade.”

As the perimeter columns are raking, and unstable until the building is complete, temporary bracing had to be installed within the steel frame, which will be removed once the floors have been cast and the structure reaches its permanent strength.

This temporary stability requirement presented a complex challenge and, using 3D modelling, William Hare developed a 40-step temporary works sequence to allow the building to be safely erected with a minimum of temporary works.

The latter point being an important criterion as too much temporary steelwork would have impeded the follow-on trades on this constrained site.

The northern part of the structure features an open double-height space for the entrance foyer, which will accommodate one of two steel staircases on the project, the other being an emergency exit located along the rear elevation.

Adjacent to the foyer, the building façade juts outwards to form one of its two feature fins. The main façade begins again 5m inside of the fin’s finishing tip, with the area in between infilled with glazing.

The uppermost part of the project, consisting of the rooftop garden and timber-framed pavilion, is surrounded by a 2m-high wall that provides the space with some privacy.

The parapet frame is formed with stub members that are bolted to the top of the main steel columns, in readiness for the cladding. The top of wall has an undulating form and this is created by the parapet, which came to site as a series of prefabricated and welded sections, made from individual 800mm-long facetted channel sections, which were then bolted together onsite to form the entire rooftop surround.

Maggie’s is a national charity which provides support to people with cancer, their families and friends. Maggie’s centres are built in the grounds of specialist NHS cancer hospitals and offer social, emotional and practical help to anyone living with cancer.

The centre is scheduled to be open in April.