Projects and Features

Steel spans motorway junction upgrade

Helping to create better connections and smoother traffic flows, steel bridges and gantries are an essential component of the M25 Junction 10 improvement works.

FACT FILE

M25 Junction 10 Improvement Scheme

Main client: National Highways

Main contractor: Balfour Beatty

Structural engineer: Atkins

Steelwork contractor: Nusteel Structures

Steel tonnage: 1,800t

Circling London, the M25 is the UK’s busiest motorway, providing an essential transportation link for not just the south east of England, but the country as a whole. A huge volume of traffic uses the road every day, with Junction 10, the A3 interchange at Wisley in Surrey, one of the most used stretches of the highway.

According to National Highways, 270,000 drivers use the junction every day, causing large queues and heavy congestion on a daily basis. It also has one of the highest recorded collision rates across England’s motorway and major A road network.

To alleviate these problems, a £317M improvement scheme began in 2022. The project will improve safety and journey times, reduce congestion and increase capacity.

The improvements to the junction include four dedicated free-flowing left turn slip roads to reduce queuing between the M25 and the A3, widening the M25 from three to four lanes through the junction, widening the A3 from three to four lanes either side of Junction 10, and providing better routes for pedestrians, cyclists and horse riders.

The scheme also features some of the most extensive environmental work ever carried out by National Highways, restoring over 25 hectares of heathland as well as planting new woodland.

Roads Minister Richard Holden, says: “Our road network is a vital component of our economy and investing in this major upgrade will create hundreds of high-quality jobs, significantly reduce congestion at one of the busiest intersections of the strategic road network and enhance safety for thousands of motorists each day.

“These improvements will boost links to major economic hubs like Heathrow or the ports in Kent, making it easier for businesses moving goods across the country, as well as small businesses across Surrey and the South East and families going on holiday too.”

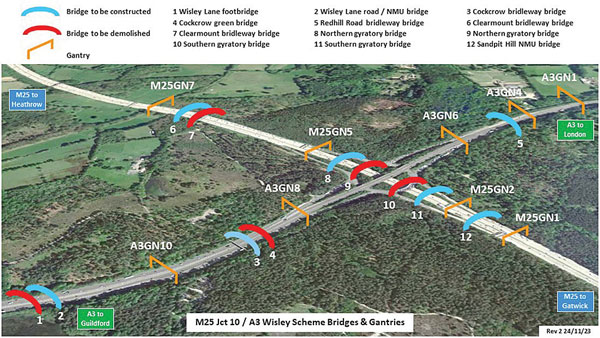

Providing an essential element to the overall scheme, structural steelwork is being used to construct three vital bridges and a number of gantries [see box]. In total, there are eight new bridges being constructed for the scheme. Steelwork is being used for the three longest span bridges, as the material is quicker to assemble and erect, thereby minimising the disruption.

Working on behalf of main contractor Balfour Beatty, Kent-based Nusteel Structures is fabricating, supplying and installing the steelwork package.

The first steel bridge structure to be installed was the Sandpit Hill footbridge, which spans the M25 and will improve links between Chatley Wood and Ockham Common for pedestrians, cyclists, and horse riders.

Said to be one of the longest footbridges on the M25, the 91m-long structure was fabricated and then delivered to site as two 45.5m-long Warren trusses, each weighing 47t. The trusses each span a separate carriageway and are supported by an abutment on either side of the motorway, as well as a central pier.

In order to keep traffic disruption to a minimum, the bridge was installed during two separate weekend motorway closures. Brought to site as two complete bridge sections, each Warren truss was installed using a 450t mobile crane.

The installed structure is the first footbridge to be built at this location and forms part of National Highways commitment to create a new 5km route that will connect with many existing paths, tracks, and bridleway.

Jonathan Wade, National Highways Senior Project Manager for the M25 J10 upgrade, says: “We’re keen to make sure that our scheme benefits the local community as well as motorists, and this new footbridge will make crossing the M25 much safer and easier for pedestrians, cyclists, and horse riders.

“The opening of the footbridge will be a key milestone for the project.”

The Sandpit Hill Footbridge is due to open this coming Autumn once work to the surrounding embankments is finished.

Located a few hundred metres away, another similar structure is due to be installed this Summer. Spanning the A3, 400m north of the Junction 10, the Redhill Road Bridleway Bridge is also a Warren truss structure, which is also being fabricated and supplied in four sections, each up to 30m-long.

The third bridge Nusteel Stuctures will be installing is the Clearmount Overbridge, which will span the M25, west of Junction 10. Replacing an existing bridge, the new structure is required as it will also span the junction’s extended slip roads.

The bridge, which will primarily be used as a foot, cycle and bridleway, will also be used by light vehicles, as the structure serves a number of private properties either side of the motorway.

Fabricated from weathering steel, which develops a rust-like aesthetic after several years’ exposure to weather and eliminates the need for painting, the bridge has an overall length of 61m.

The bridge is formed with two 2.5m-deep plate girders, weighing 62t each, which are connected by a series of cross beams.

The girders will be delivered to site in three sections and the bridge will then be fully-assembled in a yard located close to the structure’s final position.

Once the steelwork is fully assembled and the concrete deck installed, the entire bridge, which will weigh 500t, will be transported and jacked into its final positioned using SPMTs.

“One of the project’s main challenges is to keep disruption to a minimum, even though the bridges and gantries require motorway closures when they are being installed,” says Balfour Beatty Project Director Howard Williams.

“Assembling the bridge offsite and then using SPMTs to transport and install the complete structure is the quickest method. We will only need to close this section of the M25 for one day.”

Junction 10 steel gantries

Nusteel Structures is fabricating, supplying and erecting 19 gantries for the Junction 10 scheme. Due to their size and overall design requirements, steelwork is the most economical solution for the structures.

There are 11 portal gantries in the package, four of which are super-span structures measuring 66m-long and weighing 150t each. These gantries will span the entire width of the widened M25 or A3, supporting an array of signage.

Supported by 5m-high twin leg trestles and fabricated from box sections, the gantries are designed as 1.2m-wide trusses, with each side connected via cross members that also support a steel access deck. Both sides of the truss have a top and bottom chord, which are connected by a series of cross bracings.

Fully painted at the Nusteel facility and with signage bracketry welded in place, the super-span portal gantries are being delivered to site in three sections. These are then assembled onsite before the complete unit is lifted into place with a mobile crane during an overnight road closure.

The company is also supplying a further seven smaller portal gantries, as well as eight cantilever gantries. The latter are supported by a single 1,219mm-diameter CHS column and will consist of four access structures (containing a walkway), three non-access gantries (no walkway) and an Advanced Directional Sign structure.