SSDA Awards

AWARD: Lord’s Cricket Ground, Compton & Edrich Stands Redevelopment

Structural steelwork has played an integral role in the redevelopment masterplan of the spiritual home of cricket with the delivery of two new three-tier stands.

FACT FILE

Architects: WilkinsonEyre

Structural engineer: Buro Happold

Steelwork contractor: Severfield

Main contractor: ISG Construction

Client: Marylebone Cricket Club

Forming part of Marylebone Cricket Club’s (MCC) ongoing masterplan to redevelop the world-famous and historic Lord’s Cricket Ground, two new stands have transformed the Nursery End of the ground.

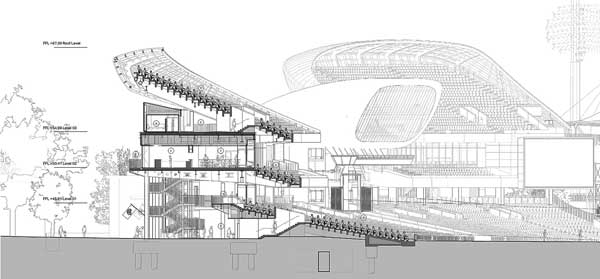

The new Compton and Edrich stands are located either side of the distinctive media centre and their three-tier arrangement increases capacity from 9,000 to 11,600 seats accompanied by two new main sponsor corporate boxes.

The redevelopment vastly improves sightlines, removes obstructed view seats, creates new wheelchair spaces and additional accessible seating, and adds a steel-framed roof, which partially covers the top tier.

The structural challenge was to achieve a light airy feeling to the whole development and very open circulation at ground level, with the outer perimeter of the stands being conceived as being a lighter colonnade using slim columns.

“The design programme presented a significant challenge for which Buro Happold carried out a detailed design, programming and cost option study which determined steel being selected for the main frame, where the initial project assumptions had been for concrete,” explains Buro Happold Senior Project Consultant Paul Eddleston.

“Sports projects typically need to respect the event calendar and this was no exception. Optimising the design for minimum construction time enabled the ambitious programme to be realised, although the programme developed during phase one of construction coincided with the COVID-19 pandemic and the cancellation of spectator sports.”

The structural layout of floors and seating responded to the functional requirements with the overall shape developed to complement the media centre. Each stand was spatially offset from the media centre so that the new elevation could be read individually but also allowing the three elements to be seen as a single new composition.

The structural framing developed to being a moment frame in two directions. In cross-section the structure is largely supported on two main columns, with further support to the lower tier. The outer column being pin-ended to respond to the aesthetic requirement of presenting a lighter colonnade façade, whilst the inner column, coupled with the bending resistance of the rakers, provides the lateral and longitudinal strength and stiffness.

To achieve this, the inner column is a 1,400mm × 500mm fabricated box with 100mm thick base plates anchored with Macalloy bar assemblies. The lower tier was not utilised in the radial stability due to its variable relationship to the primary frame around the stands and was isolated by the use of a movement bearing at the connection to the main column.

The steelwork is largely exposed in the completed structure and therefore design and detailing of the connections and position of splices needed to respond to the aesthetic requirements, as well as cater for the significant forces being transferred through them.

To develop the required structural stiffness, the rakers were designed to be continuous through the main supporting column. This required them to be deep fabricated sections. The back-span element was designed to gently taper to the outer façade to maintain the aesthetic brief for the external view. The deep section has significant service openings through the web which allowed for M&E to be contained within the structural depth.

Design of the structure and foundations had to contend with a shallow depth Thames Water tunnel running through the footprint of the stand. This straight tunnel interfered with the radial structural grid which required special foundations on some grids to transfer loads away from the tunnel.

The roof form is created by a series of curved, plated rafters located on primary grids which in-turn support the timber waffle (purlins and radials) and the tensioned membrane roof covering. An important visual aspect of the roof was to develop a smooth line for the inner dripline of the canopy forming the leading edge. This required all site bolted connections to be maintained and hidden within the Circular Hollow Section diameter, providing a near seamless continuous member.

The complex forces generated within this member, due to its geometry and structural demands, made this particularly challenging and required detailed analysis of specific rather than global forces and careful positioning of splice locations.

The project was challenging in terms of the complex architectural steelwork and very tight offsite lead-in and construction programme. There was less than a year for the old stands to be demolished, all the new piling and foundations installed, and the new stands built, in time for what would have been the start of the 2021 cricket season (postposed due to COVID-19 restrictions).

“Offsite manufacture was a major benefit of using steelwork as it meant the erection of the stands could be done quickly and efficiently,” says Mr Eddleston. “As there were many awkward interfaces between the steelwork rakers and precast terrace units the use of BIM allowed the design team to ensure co-ordination in the 3D environment using the fabrication models for both pre-fabricated elements.”

The offsite lead-in period was condensed further by a detailed value engineering process, involving Severfield, ISG and the design team, which ensured the contract was as effective and cost-efficient as possible – and ultimately ensured that MCC provided final sign-off for the project to go ahead.

Summing up, the judges say the new twin stands have an apparent easy symmetry that belies the many difficulties of planning sensitivities, timetable, site and ground constraints that were overcome.