Projects and Features

Alternatives to Portal Frames

Steel sheds are usually portal frames. This is a well-established form of construction, but there are reasons for other types of frame to be considered. John Rushton reports.

FACT FILE: Centennial Park

Architect: EPR Contractor: HBG

Steelwork Contractor: Graham Wood Structural

The dominant form of steelwork structure used in UK single-storey buildings is the steel portal frame. Columns and rafters rigidly jointed at the eaves provide a more regular distribution of loads than is achieved with “simple” jointed steel frames. Two sizes of rolled sections are traditionally used with a haunch welded at the eaves joint. Familiarity of building professionals with this structural solution has made the term “portal frame” synonymous with single storey steel construction in the UK.

This contrasts with the ‘other parts of Europe’ where simple jointed precast concrete columns and beams compete strongly where spans range up to 30m.

The success of the steel portal frame is a tribute to the design and construction methods developed by the UK steel industry over the past 40 to 50 years. Similarly a strong precast concrete industry has influenced continental construction practice.

Drawbacks of portal frame construction

A layman`s criticism of modern steel portal frame construction might be:

- Why put the deepest part of the frame, a haunch, at the lowest part of the roof, it increases the overall building height? And the extra unusable roof space may need heating

- Why use columns too large to be accommodated within wall thicknesses. This generates either a buttressed external appearance with high cladding costs or reduces useable internal space

- Why disguise the roof shape and gables by mimicking the appearance of a flat roofed building? Parapet upstands are not only costly but gutters are needed which can leak inside the building

These drawbacks are implicitly accepted as the norm in shed construction even to the extent that it is standard surveying practice for the measurement of internal shed space to ignore the area lost by perimeter columns. This contrasts with offices where column areas are deducted.

If a modern steel portal frame was introduced as an “innovation”, in a market dominated by other materials or structural forms, it might not be the automatic choice. This applies in particular to smaller buildings which form the bulk of the shed market.

Current portal frame configurations are at an intermediate stage in an ongoing dynamic progression of steel construction over the last 50 years.

Early portal frames did not have haunches and their columns could be set within wall thicknesses. A review of the factors which have influenced change can help us consider future developments.

Early portal frames

In 1945 the first edition of McKays Building Construction noted that “wood is still preferred to steel for unceilinged roofs”. Large spans in steel are acknowledged and it illustrated trusses spanning 20 to 40 ft using 2in x 2in angles, typically with riveted joints. A slate or asbestos cement roof sloping 30 degrees is supported off timber purlins spanning 12 ft.

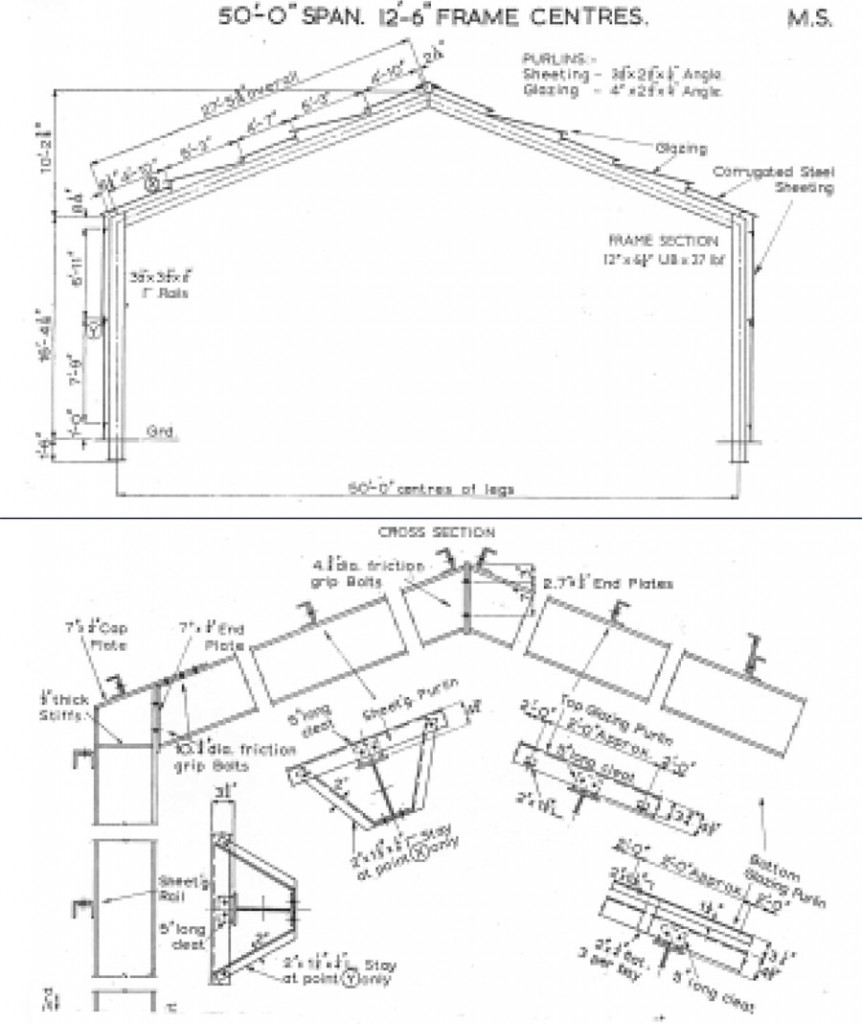

Fifteen years later a greater range of cladding types was available. Trusses with simple spans of 30 to 70 ft (9 to 21m), had roof slopes of about 15 degrees controlled by the minimum slopes of such materials as “Everite” double six asbestos cement roof sheets. Frame spacing would have been approximately 12 feet 6 inches (3.8m) consistent with the spanning capacity of 3in x 2in (90 x 65mm) rolled steel angle purlins. Steel was in short supply in the 1950’s; the solution has a minimum material weight and a high fabrication content.

In the early 1960’s portal frames were gaining general acceptance. McKay’s Building Construction again provides a snapshot of construction practice at the time. The 1961 edition suggested that a portal frame may be cheaper than simple construction dependent “on the frame number required to offset the cost of welding jigs”.

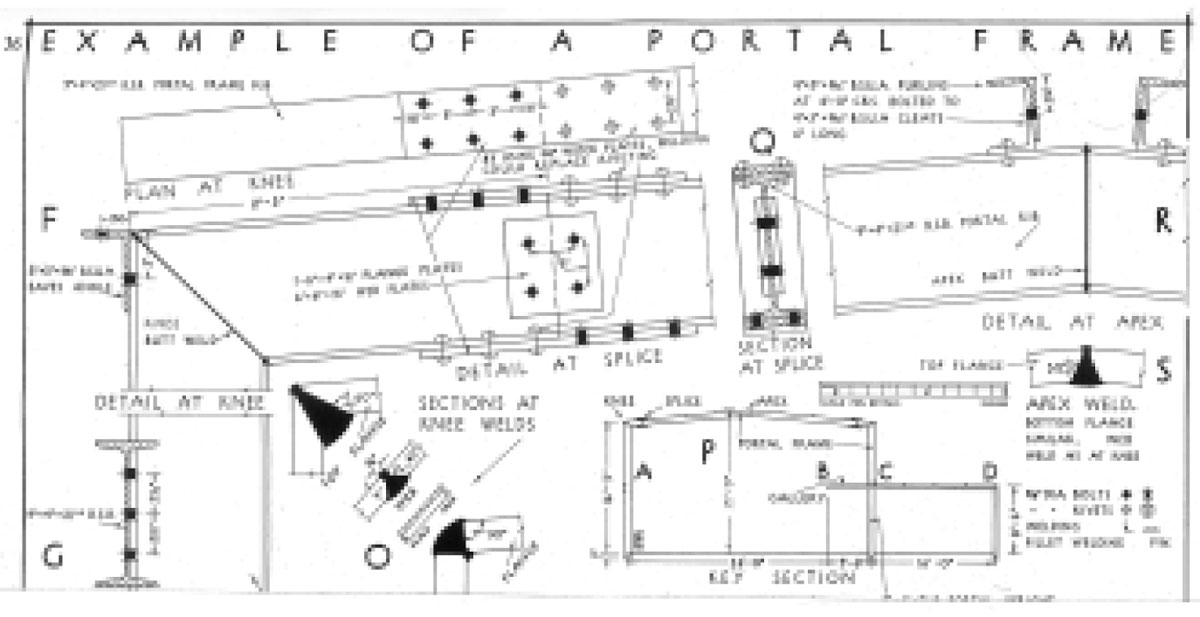

In this early example (fig. 2) of portal construction, spanning 31 feet 6 inches (10m), the roof slope has been reduced to 5 degrees by using 22 gauge steel decking. The frame uses butt welding at the eaves without a haunch. A riveted and bolted rafter splice is used with an apex butt weld. Columns are 9 inches (225mm), purlins are rolled angles limiting the frame spacing to 12 feet 6 inches (3.8m).

In the same publication cold formed steelwork is offered as a potential solution where “loadings are not too heavy”. Light gauge trusses at 9 feet (3m) spacing span 36 feet (12m). The purlins are 10 gauge (3.2mm) 4″ x 2″ box channels. Another portal frame example is described in BCSA Publication No. 24.1964.

Fig. 3 shows an example which has a 50 foot (15m) span, a roof slope of 22 degrees, and hot rolled angle purlins limiting frame spacing to 12 feet 6 inches (3.8m). Bolted apex and eaves connections are detailed with high strength friction grip bolts, no downstand haunch is required and 12 inch (305mm) deep columns are used.

“Shed” buildings today

Storage, repair and manufacturing were the traditional activities in sheds. Now low-rise single-storey buildings include supermarkets, retail parks, call and data centres and offices with light manufacturing space.

The office content in portal frame buildings can be 30 to 40% of the available space built as an office. Storage area mezzanines can further increase the office content.

Typical shed clear spans are now two or three times greater than 40 years ago.

A review of recent building projects, excluding sheds built for specialist use such as highbays and vehicle depots etc, showed portal frames being used in 14 buildings with less than 20m span; 33 in the range 20 to 30m; and 7 in the 30 to 40m range. Some rafter/haunch depths on these spans approach 1.5m with frames at 9m spacing and deep columns in the perimeter space.

Steel construction developments: the positives

Technological and manufacturing changes over the last 40 years have directly influenced the frame designs we now have, making some old construction practices obsolescent:

Developments in cold forming of steel strip into light structural steel sections led to the replacement of hot rolled steel purlins and rails. The spanning capability of the new sections has been progressively increased and main frame spacing of 10 to 12m is achievable. New forms of purlin/decking systems, standing seam, composite panels etc. have been developed and roof slopes can be reduced to 3 degrees.

By lowering the ridge height the unusable volume above the bottom of the haunches is reduced. The parapet height required to conceal the ridge at gable ends can be lowered reducing the height of the building elevations. Between 1960 and 1990 the cost ratio of labour and material changed from 1.0 to 2.88 (ref.3). This change has encouraged the use of fewer frames. Deeper steel rafter and column section sizes derive from this change. There is a greater reliance on standard approaches to design and detailing to maximise repetition and minimise design office time.

Steel construction developments: the negatives

Computer design programmes now permit analysis of options and section design to be rapidly performed on portal framed buildings by frame designers dedicated to frame cost reduction. Evaluation of alternative frame solutions to a similar level of technical rigour is relatively costly and time consuming.

The design of the building can become component-led and issues such as longer term building value, flexibility and innovation through change can be neglected.

Lowest cost frame solutions, if generated in a culture holding the view: “What did we do last time? It’s only a shed”, are not consistent with the high costs associated with site development. Construction projects are more complex, usually requiring planning contributions and environmentally sensitive, sometimes costly, substructure solutions.

Future

Buildings required to meet air leakage criteria and lower energy use could generate the next stage in the development of shed framing. Steel decking spans have been increasing steadily in the composite floor industry; more use of deep decking and cassette systems to span between frames, perhaps exploiting diaphragm action is likely.

Plate girders, Cellform and Fabsec sections can be tapered. A change from a portal, with rigid eaves joints, to braced simple construction, demands mid span strength which can be provided at the apex with a deeper section. At the eaves haunches are eliminated and overall building height reduced.

With a change in structural form shallower column sections can be flush with the perimeter walls and column positioning is no longer dictated by rafter location. The positioning of door framing or the economics of the cladding spanning characteristics can then control perimeter column setting out.

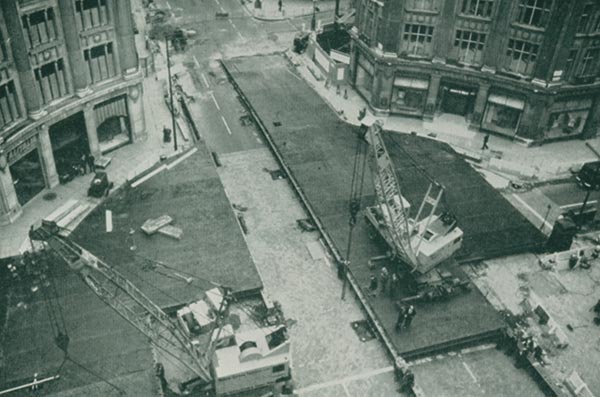

For example, at Centennial Park Phase 2, (figs. 1 and 4) for Slough Estates, a change from portals was cost justified as height was reduced and cladding saved. As the use and demands on shed buildings continue to develop, approaches to the design and manufacture of structures meeting the current challenges need to acknowledge the potential for new solutions.

It may be that the building you are financing, designing, or manufacturing might not “only be a shed”.

John Rushton is a Partner of Peter Brett Associates.