Technical

AD 330: Open top box girders for bridges

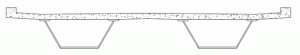

Recently there has been an increase in the use of ‘open-top’ boxes for the creation of composite box girder bridges. Typically, they are employed where the span is in excess of about 50 m and a pair of trapezoidal sections are used with a common deck slab, as shown in Figure 1. The open boxes are erected first and the slab is then cast in situ.

To stabilise the narrow top flanges during construction, cross bracing is provided at moderate spacing (4 to 7 m spacing). The guidance given in SCI publication P140 suggested that such bracing provided effective lateral restraint to the top flanges and that the effective length of the top flange (for lateral buckling) could be taken as 0.85 times the spacing of the bracing (considering the flange as a chord to a truss). However, this presumption relied on there being sufficient warping stiffness of the channel-like section to prevent an overall lateral torsional buckling developing before local buckling between bracings.

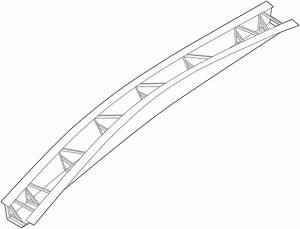

With the use of inclined flanges, the bottom flange of such box sections can be quite narrow and this means that the warping stiffness is quite low. Overall lateral torsional buckling, with a half wavelength equal to the span, can then occur, in the form shown in Figure 2. This can occur at relatively low loads (i.e. with only a small factor between the elastic critical load and the load at the wet concrete stage) and at a much lower load than would cause buckling of the top flanges between bracing positions. Even when there is sufficient factor between design load and elastic critical load, the low warping stiffness could permit significant twist, sufficient to allow unacceptable rotation at midspan

(the slab surface would have an unacceptable transverse slope).

Designers should therefore consider this mode of buckling during construction and determine its elastic critical buckling load. If the open top section is too sensitive to that mode

of buckling, either a wider section should be used (although it may be impractical to choose a suitable geometry) or plan bracing should be provided at top flange level.

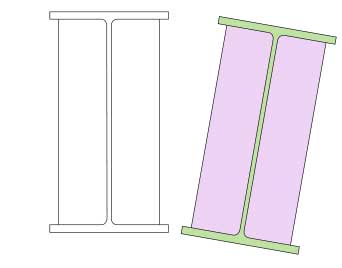

Plan bracing at or near top flange level creates a ‘pseudo-box’ and thus develops a torsional stiffness comparable to the St Venant torsional stiffness of a closed box. This torsional stiffness is much greater than the warping stiffness of the open section. However, plan bracing at top flange level is very inconvenient for slab construction (its presence conflicts with permanent formwork and the slab reinforcement). Bracing can be provided just below top flange level (and connected at cross bracing positions) but the designer must them consider its influence in the permanent condition. Such bracing will be stressed by overall bending of the composite box and, since the members are slender, they may tend to buckle in midspan regions, although such buckling is not critical (the contribution to bending resistance is not needed) and the load they carry will simply be shed. Perhaps more significantly, the fatigue effects at the connection of the bracing need to be considered. Alternatively, the plan bracing could be removed but this would require access inside the box and is very undesirable for health and safety reasons. Plan bracing need not be provided along the whole length of a span. It may be sufficient to provide plan bracing at support regions and at midspan regions but in such cases further modes of buckling will need to be considered – a 3D elastic buckling analysis would be essential.

Contact: D C Iles

Tel: 01344 636525

Email: advisory@steel-sci.com