50 & 20 Years Ago

40 Years Ago: Progress Report on the Severn Bridge

Taken from Building with Steel, 1965

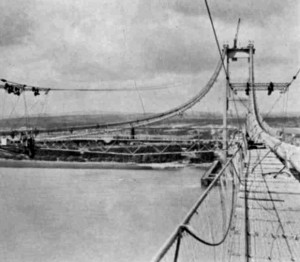

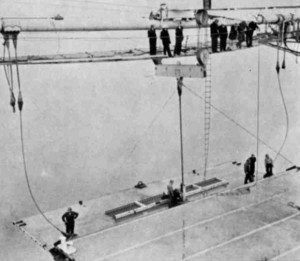

A bridge across the Severn has been thought about and talked about for do long that now, when it is approaching actual completion, one can hardly believe in its reality. Yet there it is in its sheer beauty of line and grace straddling the river, gathering up from the river itself the 88 steel deck units which combine to make the complete deck or roadway. Each of these units, which are in high stress steel, weighs 130 tons and the total weight of steelwork thus represented by the completed deck is approximately 12,000 tons.

Nearly everything about the Severn Bridge is unusual and original. Although a similar type of bridge to the Forth Road Bridge opened by the Queen last September (1964), the Severn has the advantage of development work carried out after the Forth Road Bridge design was completed: this work included additional aerodynamic testing which paved the way for an entirely new design to be created for the Severn Crossing.

Whereas the Forth Road Bridge has latticed stiffening girders and separate roadway decking, the Severn bridge is having a single all-welded steel box girder with the road running on the upper surface and the footways and cycle tracks cantilevered out at each side: this box girder is suitably shaped to minimise the effect of wind forces and to ensure aerodynamic stability. Saving in both weight and cost is achieved by these new methods.

The sequence of fabrication and erection operations is unusual – fabrication of elements, metal spraying and other anti-corrosion processes are being carried out in three separate works in the country then dispatched to a works in Chepstow where they are welded together, launched and finally floated down the river Wye into the Severn and so under the new bridge: each unit is then hoisted from the river to its position on the bridge.

There is here a considerable triumph for welding which contributes greatly to the slender beauty of the bridge.

The Severn Bridge design has created much interest in America where the Verrazano Bridge was opened last November. The British design, with its greater economy in the weight of steel used and consequent saving in cost, has produced lively comment and comparison, much of it favourable to the British design.

The Severn Bridge is part of the grand project which will save 50 miles on the journey from Southern England to South Wales: the project includes the Beachley Viaduct and Wye Bridge with eight miles of approach road and will be finished next year (1966).