Projects and Features

Vital Greenwich link installed

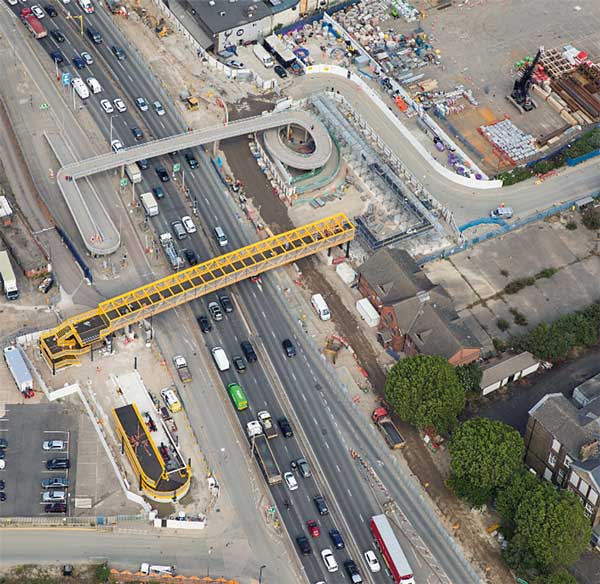

Crossing the Blackwall Tunnel Approach Road, a new steel footbridge forms a vital, as well as the only, means of pedestrian access between the two halves of the North Greenwich peninsula.

FACT FILE

Boord Street Pedestrian and Cycle Bridge, North Greenwich

Main Client: Transport for London (TfL)

Architect: dRMM

Main contractor: Riverlinx CJV

Structural engineer: Arup

Steelwork contractor: Briton Fabricators

Steel tonnage: 380t

Forming part of the wider Silvertown Tunnel project (see below), which will deliver London’s first new road tunnel under the River Thames in more than 30 years, a replacement steel footbridge has been installed.

Spanning the busy A102 Blackwall Tunnel Southern Approach Roads, the Boord Street Pedestrian and Cycle Bridge is positioned 40m south of an existing 1960s-built concrete bridge, which was recently demolished.

As well as providing an important role in connecting walking and cycling routes across the Greenwich Peninsula, the new bridge is also needed as the road layout of the A102 is changing.

The new layout will be needed as the road will lead to, and serve, the southern portal of the new Silvertown Tunnel, as well as maintaining its existing route to the Blackwall Tunnel.

The overall scheme, including the new bridge, is being delivered by Riverlinx, a construction joint venture (CJV)between BAM Nuttall, Ferrovial Construction and SK ecoplant.

Working on behalf of the CJV, Briton Fabricators has fabricated, supplied and erected the bridge.

Founded on CFA piled foundations, the 57m-long main span of the bridge is formed by a pair of Warren trusses with 200mm × 200mm × 12.5mm SHS diagonal members that connect the top and bottom chords of each truss.

Supporting the 4.5m-wide deck and spanning between the bottom chords of the two Warren trusses is a series of cross member deck transoms, which are 200mm × 200mm × 8mm SHS sections, while the top chords of the trusses are braced by the same sized SHS members spaced at 4m intervals. Stainless steel bird deterrent wiring is positioned across these top booms.

Providing a fully accessible bridge, the structure is designed to modern standards and incorporates lighting embedded within the main span’s parapet posts. Briton Fabricators also supplied and installed stainless steel mesh cladding to the sides of the bridge and its access ramps and stairs.

The choice of stainless steel mesh was made as this product will prevent anti-social behaviour and allow inspection and cleaning of the steel structure.

According to architects dRMM, the lighting design has been developed to provide appropriate functional lighting, while enhancing the form, texture and tone of the bridge and associated ramps, stairs and public realm.

Lighting is used to represent the direction of travel of users as they traverse the footbridge, using diffuse lines of light to create a varied but complementary and cohesive design which strengthens the structural form of the bridge.

The lighting will aid users at night, but during daylight hours, people will be able to fully observe the project’s steelwork, which has been painted yellow as this colour is said to be uplifting and welcoming.

A steel structure was chosen as it enabled the bridge to be prefabricated offsite, which minimised disruption to the busy A102.

In design terms, the selection of a steel through truss solution provided a structure capable of spanning 57m, while minimising the structural depth below footway level. This, in turn, minimised the length of the approach ramps required at each end of the bridge and the land area required for those ramps and stairs.

The bridge’s main span was fabricated at Briton’s Nottingham facility as a complete section. It was then painted and a non-slip surfacing was applied, before it was cut into three pieces, bolted connections formed and then delivered to site.

Once the three pieces were onsite, they were re-assembled into a complete section and lifted into the final position using a single 800t-capacity mobile crane. This procedure was undertaken over a weekend closure of the Blackwall tunnel.

With the main span in place, the ramps and stairs on either side of the bridge, which are structurally independent, were erected over the following weeks. In total, 314 linear metres of steel-framed ramps have been installed.

Silvertown Tunnel

Following a similar route to the alignment of the IFS Cloud cable car, the Silvertown Tunnel project has been designed to ease congestion around the adjacent and existing Blackwall Tunnel.

Tunnelling work for the 1.4km-long twin-bore tunnel has recently been completed, using just one tunnel boring machine (TBM), with a diameter of approximately 12m.

Helen Wright, Head of the Silvertown Tunnel programme for TfL, said: “The completion of tunnelling works on the Silvertown Tunnel is a massive milestone, and to complete it in under a year shows the hard work and close collaboration of everyone working on the project.

“Engineers are working around the clock to deliver this project with minimal impact to those living, working and visiting the local area and we remain committed to delivering a project that supports growth in the local area and provides new public transport connections across the river.”

Juan Angel Martinez, Project Director at Riverlinx CJV said: “This is such an important milestone for the Silvertown Tunnel construction and I would like to congratulate everyone involved in delivering it. The technical expertise, focus and collaboration of this team have enabled us to safely complete the main tunnel drive to programme. Riverlinx is now focusing on the next stages of construction to successfully deliver this vital piece of infrastructure for London.”

Structural steelwork is playing an important role in the tunnel works. A total of 247 CHS props, ranging in length from 9m to 41.5m, are being supplied by Severfield to support the 600m of access ramps at both ends of the tunnel. Overall, the company is supplying 4,000t of steelwork for the project, including 600t of waler beams.

The Silvertown Tunnel is expected to be completed in 2025.