This month's featured stories

Tackling the residential market

The use of steel in multi-storey residential projects is increasing. It offers economic and fast solutions.

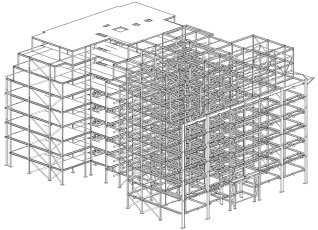

No. 60 Vauxhall Bridge Road.

TEAM

Client Wates Construction

Architect PRC Fewster Architects

Structural engineer Peter Dann Consulting Engineers

Steelwork design Bourne Steel Ltd

Steelwork contractor Bourne Steel Ltd

.

COST

Project value £14 million

Steelwork value £1.6 million

Tonnage 790 tonnes

Floor area 9,500m²

Roof area 1,100m²

.

TECHNICAL

Design code BS 5950

Structural analysis CSC S-Frame

Steel grade S355J0 & S275JR

.

APPLIED PROTECTION

Corrosion Epoxy zinc phosphate

Fire Off-site intumescent to bottom flange only

There are strong positive trends in the UK market for residential construction. This market fulfils the need for accommodation units in the “four H’s” – Hotels, Hostels, Hospitals and Housing – with the latter being the most vigorous currently as the nation’s demography changes and the number of new households continues to grow rapidly. This demand is met by steel frames, which provide fast, accurate and reliable solutions with off-site prefabrication. The solutions are also well suited to the incorporation of the latest thinking in terms of modular and volumetric service pods that are becoming increasingly common across Europe.

STEEL SOLUTIONS

Design solutions for steel-framed multi-storey accommodation units must address four criteria: structure, fire, vibration and acoustics. It is a well publicised fact that steel frames offer economic and fast solutions for multi-storey office construction, and this is also true for multi-storey residential units. There are differences, and whilst residential units do not demand such large spans and are less regular in terms of layout, limiting the width or depth of the construction zones is crucial. Over the last six years, Bourne Steel has undertaken 27 projects for residential housing frames with the largest having a value of £1.6 million. Using this experience, Bourne Steel has developed some particular design solution.

Structure

The structural zones for columns and beams need to be limited to a nominal 200 mm dimension. The maximum column size is thus a 203 UC. Vertical bracing can be centralised in this zone by using crossed flats, and then blockwork can be built up either side of the bracings to form an external or internal division wall.

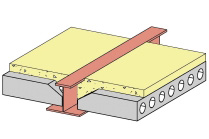

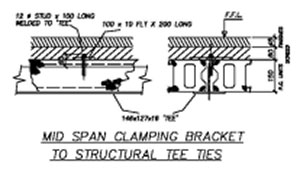

To meet the requirement for a limited-depth floor zone, Bourne Steel has developed the BourneBeam® which is a plated asymmetric section specifically tailored for such situations. The steel section is buried within the floor which utilises precast units, with an in situ topping if required. Bourne Steel offers a service to specifiers for the design of the BourneBeam, and it is most often the case that the construction stage determines the beam dimensions. This service also extends to edge beams, which are often critically loaded in torsion.

To meet the requirement for a limited-depth floor zone, Bourne Steel has developed the BourneBeam® which is a plated asymmetric section specifically tailored for such situations. The steel section is buried within the floor which utilises precast units, with an in situ topping if required. Bourne Steel offers a service to specifiers for the design of the BourneBeam, and it is most often the case that the construction stage determines the beam dimensions. This service also extends to edge beams, which are often critically loaded in torsion.

To meet the requirements for robustness, designs based on the BourneBeam offer the ability to bury the horizontal ties within the nominal 200 mm zone of the structural floor. The ties can be cambered to suit any camber in the precast units.

To meet the requirements for robustness, designs based on the BourneBeam offer the ability to bury the horizontal ties within the nominal 200 mm zone of the structural floor. The ties can be cambered to suit any camber in the precast units.

Fire

By burying the steel frame within the other elements of construction, the requirements for fire resistance are largely catered for without the need for any applied fire protection materials. If necessary, the exposed face of the BourneBeam can be coated with intumescent paint.

Vibration

Relatively small spans are typical of residential units (6.0 to 7.5 m between division walls, with rooms generally 3.0 to 3.5 m wide up to 4.5 m maximum). With such spans, and using a solution such as BourneBeam, meeting floor vibration criteria is not a problem.

Acoustics

The popular myth is that steel frames require special attention in terms of acoustic transmission, whereas in situ concrete frames do not. The fact is that both choices of framing material require that the acoustic transmission characteristics be formally addressed to demonstrate compliance with the regulatory requirements in Part ‘E’. Bourne Steel is participating in the tests being undertaken on structures built using its steelwork, and these show that economic steel-framed solutions readily demonstrate compliance with the regulations.

THE FUTURE

The dynamic nature of the construction market means that every project demands new thinking. However, there are considerable advantages to be gained by using proven solutions from previous experience.

AUTHOR

Alan Pillinger, Technical Director of Bourne Steel Ltd