Projects and Features

Steel tops sustainability study

Analysis of the emissions produced by steel and concrete in construction of an Oxford University building confirms the significant sustainability benefits of steel frames. The benefits are so substantial, says Dr Fergal Kelly of PBA, that design appraisals should place as much emphasis on CO2 as on cost or programme implications.

PBA were commissioned as structural and civil engineers for the design of a new departmental building in the Science area of Oxford in 2004. The building consists of four storeys above ground and two basement levels, with a total footprint of around 12,000m². See illustration below.

The University has a rigorous and knowledgeable approach to sustainability, encouraging the design team to set high standards. So in order to ensure a more sustainable structure for the building, PBA investigated three structural options in terms of CO2 emissions and embodied energy. The study also included emissions for haulage of materials and arisings.

Option one was a hybrid of the parallel beam system, utilising two levels of orthogonal steel beams, continuous in many locations, supporting a composite slab. Option two was a 350mm thick concrete flat slab structure. The third option was a conventional steel composite structure; however the results for this option were very similar to option one and the results are therefore not reported here.

Key Structural Considerations

Apart from typical structural drivers such as cost, programme, etc., the site location is in a congested area with poor transport access and adjacent buildings in constant use and this meant that number and size of deliveries was a key design consideration. Out-of-hours delivery was one advantage of a steel frame. Propping forces to the basement retaining walls and temporary works requirements during construction were also a factor in the choice of frame.

What is the benefit?

Under the previous set of Part L regulations, construction was typically responsible for around 10% of the energy used during a building’s lifetime. With the new Part L regulations, this value is expected to rise to around 25%. Therefore, the contribution from structure is becoming more significant. If the construction industry can reduce the construction CO2 emissions by up to say 25%, this creates more than a 6% reduction in emissions over the entire lifetime of the building.

Consider for example a renewable energy target of say 10% and its associated financial cost which may be a significant increase in the build cost. Now consider a structure which reduces emissions by 6% but achieves this without an additional financial cost and most likely at a saving. Clearly a structure that achieves an efficient reduction in emissions with little or no capital cost has a large contribution to make in sustainability terms.

Audit of CO2 emissions

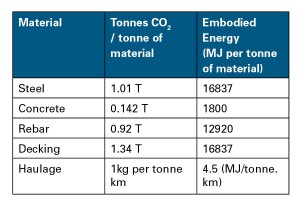

Data on CO2 emissions has been gathered from various sources and is presented below in Table 1. These values include ‘end-of-life’ considerations and therefore take account of the fact that steel will be recycled or concrete crushed and re-used for aggregate. The steel data from the International Iron and Steel Institute (IISI) represents global average figures for the products in question. It has been assumed that 85% of the steel in the building will be recycled after demolition of the building (the real percentage for a site might vary but the global figures represent the general case). Data for concrete was averaged from various web-based resources for concrete.

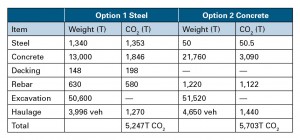

This data has been used to calculate the overall CO2 emissions and embodied energies of the two options described above. These overall values are shown in Table 2.

It can be seen in this particular case that the CO2 emissions for the steel-framed option one are 8% lower than the concrete option, resulting in a saving of 456t of CO2. (To put this into context, the average CO2 emission per person in the UK is around 10t annually). When the structure above ground was considered in isolation, the steel option had 22% lower emissions. This was a reflection of the heavier than normal steel weights in the basement structure due to propping forces.

In this case, the steel option was chosen on the grounds that the overall structural cost was comparable, the programme faster, and construction traffic to the site was reduced. It was an additional benefit that the cost and programme savings were achieved in conjunction with superior sustainability credentials.

Design development changes made since the inception of the project, such as a reduction in thickness of the basement slab have also saved around 410t of CO2 on the original design.

The values for CO2 emissions for each material were chosen to be as compatible as possible, in terms of reflecting current recycling practice. It is notable that a concurrent Life Cycle Assessment of the same building, which considers other greenhouse gases and particulates, produces a very similar result to this study.

Interestingly, embodied energy figures were similar for both options at around 6.6×107 MJ. This implies that embodied energy figures alone do not sufficiently express the sustainability of a structure, but need to be viewed in conjunction with CO2 emissions.

Conclusions

As a result of the new Part L regulations, structure has an increasingly important role to play in the overall sustainability of buildings. This brief study of the impact of a structure on CO2 emissions has demonstrated that there is significant environmental benefit to be gained from carrying out an audit of structural options. This can also be carried out on proposed design changes during the course of the project.

Ideally, an appraisal of structural options or design changes would place as much emphasis on CO2 emissions as on cost or programme implications. Reducing emissions during construction is in line with the ethos of ‘it’s easier to save energy than create it’ and can be achieved more efficiently and with less capital cost than many renewable energy measures. The study also shows that these benefits can be achieved in conjunction with cost and programme savings, which can only encourage clients and designers to adopt such policies on future projects.