Projects and Features

School work in the frame

Using steelwork as the framing material for a school project in south London has helped the team coordinate the programme around students and negotiate site constraints.

FACT FILE Prendergast Hilly Fields College, Lewisham, LondonMain client: Lewisham Council

Architect: HKR Architects

Main contractor: Costain

Structural engineer: Ramboll

Steelwork contractor: Caunton Engineering

Steel tonnage: 400t

The reconstruction of Prendergast Hilly Fields College forms part of the London Borough of Lewisham’s Building Schools for the Future (BSF) programme. One of four schools Costain is building for the programme, this project will be delivered through an £18M design and build contract.

Prendergast Hilly Fields College is said to be one of the most successful community schools in the UK. It operates across two sites, one known as Park Site, which consists of a Grade II listed building (currently being renovated) and the nearby Adelaide Avenue site, which accommodates the majority of the educational facilities and is the location for the steel construction work.

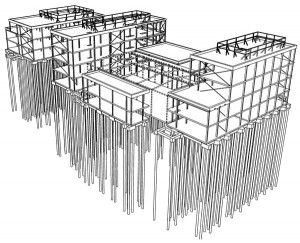

The Adelaide Avenue site previously consisted of four blocks, three of which have now been demolished, making room for three new buildings. A fourth existing structure (block E), accommodating classrooms and a sports hall has been partially demolished, with the sports hall retained and incorporated into the new scheme.

Pupils continued to use block E throughout the construction programme, only ceasing to utilise the classrooms once new blocks were finished, which allowed the students to decamp.

This meant a phased demolition and construction process had to be employed, whereby the partial demolition of block E was only undertaken once two of the three new blocks were completed.

“Coordination around the school’s activities was a key driver in choosing steel,” says Eddie McKenna, Costain Project Manager. “Steelwork has played a crucial role in keeping the project on schedule.

Blocks 2 and 3 contain a single row of class rooms on each floor and a corridor positioned along one elevation

“Its early procurement meant we were able to start on time, while Caunton’s expertise, particularly on the interfaces with the existing structure, has allowed the steel frames to be erected to a strict methodology.”

Known as blocks 1, 2 and 3 the new buildings are principally finished in blue brickwork with punched timber windows and curtain walling. They are structurally independent steel braced frames, featuring cross bracing – located in perimeter walls, stairwells and lift shafts – for stability.

Internally, the buildings are constructed from blockwork which is said to provide a robust facility capable of withstanding the heavy foot loads of pupils and staff.

Flexibility was another important consideration when choosing steel as the framing material.

“The teaching areas of the blocks could be reconfigured if the school’s needs changed in the future. Partition block work walls and steel columns could easily be removed to create larger classrooms,” says Barry Reynolds, HKR Project Architect.

Blocks 1 and 3 were erected in 2011, while the centrally located block 2 was erected either side of last Christmas. Block 2 wraps around the retained sports hall on two sides and part of this structure infills the space previously occupied by block E’s teaching wing.

Blocks 1 and 3 were erected in 2011, while the centrally located block 2 was erected either side of last Christmas. Block 2 wraps around the retained sports hall on two sides and part of this structure infills the space previously occupied by block E’s teaching wing.

Block 2 is the highest structure with four levels and contains a single row of classrooms on the upper floors. The L-shaped building’s front elevation facing Adelaide Avenue contains the new main entrance and two large dining room/ assembly/drama spaces.

Containing slightly different grid patterns, due to their varying classroom sizes, blocks 1 and 3 both have three levels, including ground floor. Block 1 is wider and contains two rows of classrooms separated by a central corridor on every floor, while block 3 accommodates single rows of classes.

All three structural frames form independent standalone blocks, although block 2 does have access into the retained sports hall.

A movement joint across this entrance space means the new build structure is completely isolated from the older existing building.

“The sports hall was built on pad foundations while the new blocks are constructed on piles. Without isolating the structures we would have had a movement issue,” explains Scott Lewis, Ramboll Project Engineer.

The overall project is due for completion this August, with the new premises fully open to students for the autumn term.

Steel goes up

Caunton Engineering erected all of the steelwork using a 50t mobile crane. The company also installed the precast floor planks, a procedure which speeded up the construction programme.

Caunton Engineering erected all of the steelwork using a 50t mobile crane. The company also installed the precast floor planks, a procedure which speeded up the construction programme.

“We erected a couple of grid lines at a time, installed the planks and then moved onto the next area,” explains Adrian Downing, Caunton Engineering Project Manager. “The site is very confined with very little available space so it was much quicker for us to do both jobs.”

The largest steel element to be erected was a 19m long × 3.8m deep truss (pictured) situated at first floor level in block 2. The large element helps create the open spaces for the halls and entrance area.

The truss was brought to site in small pieces, assembled on the ground and then lifted into place as one large element. “The site’s lack of space meant this was the only practical way of installing the truss,” adds Mr Downing.

Steelwork has also played its part in making the project cost efficient. Caunton suggested using RHS box section floor beams along all perimeters to support stainless steel angles onto which the cladding is fixed.This design not only proved to be cost efficient, it also helped the cladding contractor complete its installation more quickly.