Projects and Features

Robust shed for homebuilder

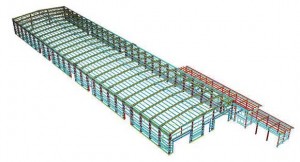

A new production facility for one of the UK’s leading manufacturers of park homes is under construction at Express Park in Northamptonshire.

FACT FILE: Homeseeker Homes, Express Park, Rushden, Northamptonshire

Architect: Tew and Smith

Structural engineer: Brian Cole Associates

Main contractor: Warwick Burt Construction

Steelwork contract: DGT Steel & Cladding

Steel tonnage: 380t

Project value: £4.5M

Homeseeker Homes currently builds its range of portable homes for residential parks in Irthlingborough, but this facility has been out grown and the company will move into its new premises in September.

Its new home will be Express Park, a large business park in nearby Rushden and this develop-ment occupies one of the last vacant lots on the site.

Main contractor Warwick Burt Construction began work at the end of last year and initially it had to level a sloping site with a large cut and fill operation.

“We had to strip out a lot of soil before compacting everything,” explains Warwick Burt’s Contracts Manager Jonathan Smith. “This left us with a levelled site which was then suitable for the steel erector’s cherry pickers to work on.”

Steelwork is founded on pad foundations which are 3.5m deep in some places, while the overall project is surrounded by concrete retaining walls.

DGT Steel and Cladding started the steel erection in March this year and all 380t was up by the end of April.

The job comprises of a 150m-long portal framed production building, an adjacent (but not attached) office building and timber store, and a separate material storage building.

The production building is a duo-pitch portal frame, with a 35m clear span and a height of 9m to the underside of the portal rafter haunch. Frame stability is provided by portal action, and to reduce differential deflection effects between the gable and the penultimate frame, the gable frames are also portalised in lieu of the traditional braced gable.

Stability to the side elevations is by tubular strut bracing, which was designed to accommodate longitudinal surge from the building’s cranes and thermal expansion forces. This design approach also negated the need for an expansion joint within the frame construction.

Ryan Thurston, Project Structural Engineer for DGT, which has a design and build contract for the steel frame, says: “The main building had to accommodate four overhead gantry cranes each with a safe working load (SWL) of 5t, in addition to dead, imposed and wind loadings.

The design consequently accommodates two cranes working buffer-to-buffer and in tandem to lift a combined SWL of 10t.

“We had to design an economical structure which was robust and this required larger sections than would normally be used on a portal frame of this size,” adds Mr Thurston.

Any movement of the frame, during wind or because of snow piling up on the roof would prevent the cranes from operating properly. The columns which DGT erected, at 6m spacings, were consequently 762 x 267 x 134 beams, while the rafters were 533 x 210 beams.

Adjoining the main production building is the office block which was required to be structurally independent from its neighbour in order to minimise noise and vibrations from the cranes.

As such, the two storey building has its own stability system. “No internal columns were permitted so we adopted moment resisting connections at first floor and roof level to create rigid frames, which has the added benefit of reducing the floor beam deflections,” explains Mr Thurston.

Stability to the gable and side elevations is performed by vertical flat cross bracing concealed within cavity walls. Further frame stiffness was achieved by incorporating the precast concrete first floor within the design model to provide diaphragm plate action.

Due to the number of openings within the front elevations the corner gable columns were designed as vertical cantilevers from the first floor level. This was done to transmit the roof plan girder reaction into the first floor level diaphragm, and through to the vertical bracing within the adjoining timber store’s rear elevation.

The timber store is a smaller continuation of the office block and is also designed as a typical portal frame. However, as the structure has an open side the wind pressure coefficients needed to be modified from that of a typical enclosed building.

Meanwhile, the material storage building is a typical portal framed structure with a plane frame stability provided by portal action and stability to the gable and side elevation by tubular strut bracing.

Mr Thurston says due to the close proximity of the site perimeter, fire boundary conditions exist to the rear and gable elevation, and as such the steel frame was designed with a separate load case for fire collapse.

The structure’s columns were designed with moment resisting bases to resist the horizontal thrust of the rafter destabilising the columns and wall in a fire. Slotted bolt holes with neoprene washers have been provided in the side rails to permit thermal expansion.

“By designing the frame in this manner the costly alternative of applying intumescent paint to the steelwork was negated,” sums up Mr Thurston.

Warwick Burt are currently cladding the completed steel framed structures and it will hand over the completed buildings in September. Homeseeker will also erect a sales office on the site, this structure will be a large modular building from its sister company – within the Shepherd Group – Portakabin.