Projects and Features

Retain and rebuild

FACT FILE

1-4 Marble Arch, London

Main client: Portman Estate

Architect: Allford Hall Monaghan Morris (AHMM)

Main contractor: Galliford Try

Structural engineer: AKT II

Steelwork contractor: Bourne Steel

Steel tonnage: 1,150t

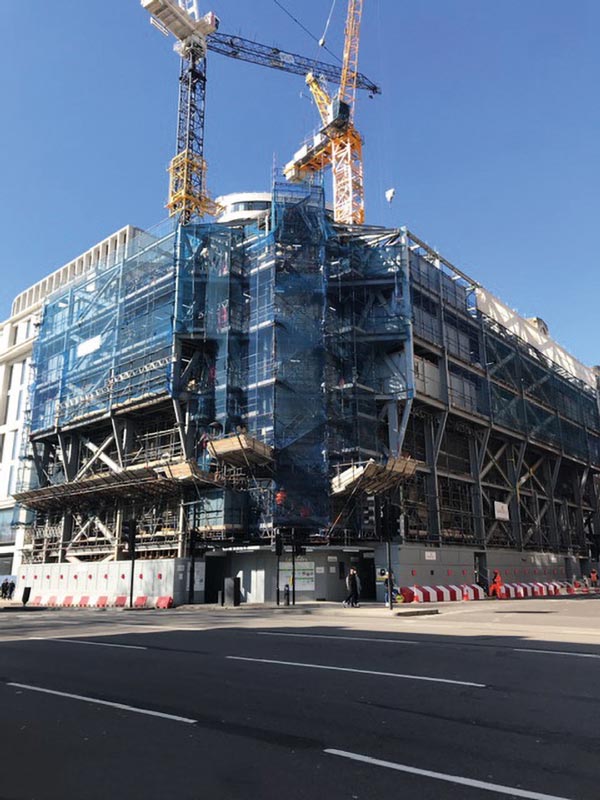

A steel-framed office and retail development in central London combines a retained façade with a new modern interior. Martin Cooper reports from London’s West End.

Protecting the capital’s historic streetscape and buildings is always uppermost in planning departments’ and developers’ minds when a new scheme is in the offing.

The march of progress cannot be halted and so one solution to the conundrum of accommodating modern and up-to-date buildings within a listed or much-loved street, is to retain facades and construct a new structure behind.

This solution has been successfully used throughout central London as well as other parts of the UK. It is a popular method, as once the construction project hoardings are removed, the general public see the same building elevations, pretty much as they were before building work commenced. The streetscape will have been preserved, but within the retained façade a new modern interior will have upgraded the address.

An ongoing example of this kind of work is 1-4 Marble Arch, which is a £55M central London rebuild project designed by leading architect AHMM.

“This is a key project for an important client, and follows are successful completion of a similar project in the vicinity,” says Galliford Try Senior Project Manager Barry Kingscote.

The nine-storey building, originally built in the 1920s, sits directly opposite the Marble Arch monument, in the heart of London’s West End. The project will see the existing façade retained from street level up to level six, while behind it a full demolition and a steel-framed rebuild is taking place. This will create three floors of retail space and above this a further seven floors of high-quality Category A office space.

Commenting on the decision to retain the facades, which run along the main Marble Arch elevation and Great Cumberland Place – the other two sides, to the north and west of the building are party walls – project architect AHMM says the work ensures the restoration, protection and reinterpretation of the existing historic architectural features.

The top levels of the façade were removed during the demolition programme and will be replaced with new stone-clad elevations that will match and complement the retained parts. Within the retained façade, new fenestrations will be added that consist of slimline steel windows.

One of the more complex parts of the project’s work, involves the ground and first floor parts of the retained facades. These are being demolished, while the structure above is fully-supported by the retention system, and replaced with new stonework and larger steel-framed shopfronts (see box).

Main contractor Galliford Try began onsite in 2019 and once demolition was complete, the temporary retention system in place and the existing basement enlarged into a two-level subterranean area, they and Bourne Steel were able to get the steelwork erection programme underway.

The new steel frame begins at the upper basement level, but the main columns are founded below this on the lowest concrete slab.

Based around a regular column grid pattern of 6.5m × 9m and stabilised by a single concrete core, the steel frame supports metal decking with a concrete topping to create a composite flooring solution for the new 10-storey building.

New steelwork connects to the retained façade steel columns via bolted connections and once complete, the new frame will support the old structure.

“They are two separate structures; the steel frame is founded on new raft foundations, while the façade is on pad foundations. So, in order to accommodate any differential movement, they are joined by a sliding connection,” explains Mr Kingscote.

The majority of the structure’s steel beams are fabricated plate girders with bespoke cells to accommodate the building’s services within their depth.

“The soffits will all be left exposed within the completed building, along with the steelwork,” explains Bourne Steel Project Manager Duncan Wyatt. “Consequently, we have applied a decorative intumescent paint finish to the beams and columns at our fabrication workshop. This has cut down onsite works, as we only have to repaint the connections and any knocks and scratches.”

The exposed interior of the office floors gives the building a modern and ‘industrial-looking’ environment. Flexibility is also at the heart of the steel-framed design, as each office floor can be occupied by a single tenant, or sub-divided into two. Flexibility also extends to level one, which has been initially designed as the upper retail floor, but can be changed into office space.

Adding some irregularity to the new steel frame, there are set-backs on each of the floors that are above the retained façade. Transfer beams are located on floors six, seven and eight in order to support the irregularly-positioned columns that help create the three steps in the building.

1-4 Marble Arch is due to complete in early 2022.

Façade retention system

While the project’s initial demolition programme was being undertaken, a façade retention system was installed along two elevations to support the retained walls that extend from ground floor up to the underside of level six.

This large L-shaped temporary steel structure is approximately 6m-wide, and extends 25m along Marble Arch and then 45m along Great Cumberland Place.

As well as acting as a temporary support, the retention system has also been designed to facilitate the removal of masonry and some steel columns (the original building was steel-framed) from the façade’s ground and first floor level. Many of the old columns have to be removed as they would have obstructed new and wider shopfronts.

“Once the main steel frame was completed, we inserted a series of steel needles (beams) through the façade to connect it to the retention system and second floor slab level,” explains Galliford Try Senior Project Manager Barry Kingscote. “They support the structure above and allow the lower part of the façade to be removed. We will then install new steel-framed windows and shopfronts.”

The needles remain in place once the work is complete, but their connection to the retention system is temporary. The installed shopfront steelwork is quite substantial as some support columns above. Weighing up to 4t and with a maximum length of 6m, the window frames are fabricated from 400mm x 400mm box sections.

The challenges of combining existing and new structures

David Brown of the SCI

The retention of the existing Marble Arch façade project highlights some of the practical issues with connections between old and new. Firstly, the existing structure may have some surprises – it would not be uncommon to find that the ‘as built’ structure differs from the construction drawings – if any construction drawings are in fact available. The materials, dimensions, locations and connections between elements may not be as expected, either when originally constructed or due to subsequent alterations. A thorough inspection is essential, although the degree of opening-up must be balanced by what is realistically possible and the resultant damage. As the original building was completed in the 1920s, the steelwork sizes might be rather different to today’s serial sizes (although many current metric serial sizes are simply the equivalent of the imperial dimensions). Tapered flanges would be one obvious difference. Section sizes and properties for historical structural steelwork can be found in a handbook freely available from the BCSA.

The second practical issue is to allow for the inevitable differences in position and level by making provision for adjustment in the connections between the existing and new. This may be as simple as detailing packing between elements, or by using slotted holes and preloaded assemblies, but adjustment is likely to be essential. The Marble Arch project involves bolted connections between the existing frame and the new steelwork, which may often be preferable to site welding. Bolting obviously involves site drilling, but avoids the analysis of the existing material, joint preparation and access issues associated with welding. Connection designers should note that thick packs reduce the shear resistance of bolts – as given by clause 3.6.1(12) of BS EN 1993-1-8.

The significance of differential settlement is also highlighted by the Marble Arch project. Any settlement of the façade will have taken place a long time ago, but the new raft foundations may settle over time, as the loading increases during the construction phase. Sliding joints have been provided, which also demand careful detailing. In combination with slots, so-called ‘shoulder bolts’ may be used, which have a part-threaded shank and an unthreaded length of a larger diameter. The nut can be tightened down to the ‘shoulder’ which is slightly longer than the plies to be joined, meaning the two plates can move relative to each other, but not separate.

In addition to the guidance in the BCSA Handbook, SCI publication P138 offers practical advice on appraisal, structural assessment, strengthening methods and corrosion protection when dealing with existing iron and steel structures.