Projects and Features

Power to the Olympics

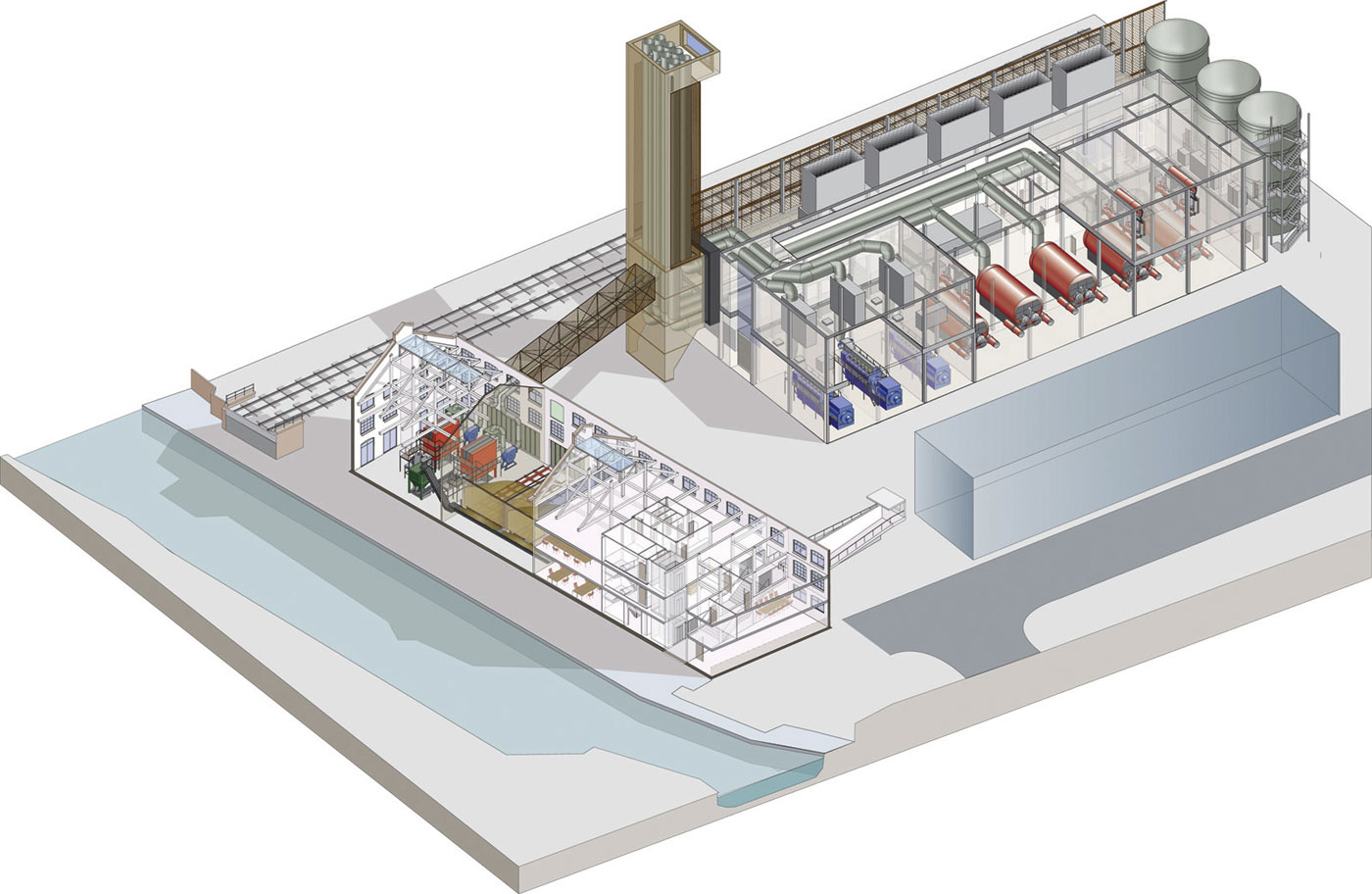

The venues and buildings on the London 2012 Olympic site will require power and to supply this need one of the most sustainable energy centres in the UK has been constructed.

FACT FILE: London 2012 Olympic Energy Centre

Owner and operator: Cofely

Architect: John McAslan & Partners

Main contractor: P J Carey

Structural engineer: Adams Kara Taylor (AKT)

Steelwork contractor: The AA Group (TAAG)

Steel tonnage:500t

The London 2012 Olympics is drawing closer by the month with many of the larger venues now either completed, such as the Velodrome, or entering the final stages of construction.

Providing the power to these buildings on the Olympic Park is a state-of-the-art Energy Centre, the largest such scheme to be built so far in the UK and certainly one of the most sustainable.

The facility will provide an efficient low carbon heating and cooling system across the site and will contribute towards the Olympic Delivery Authority’s (ODA) overall target to reduce carbon emissions by 50% across the Olympic Park.

Once the Games are over, the Centre will provide the energy for new buildings and communities that will encompass the site. To this end it has a flexible modular design allowing further capacity and new technologies to be added, as and when they are developed.

“The building’s future-proofing and flexibility were two of the main criteria for the project’s design. If new equipment needs to be installed a number of key structural elements can be removed, without affecting its integrity,” explains Stelio Papastylianos, AKT Associate.

For stability the Energy Centre is heavily braced around its perimeter by cross bracing made from large hollow sections. The cross bracing members act as tension and compression sections and it is these stability giving members which theoretically can be removed.

For these reasons a steel framed solution was chosen for the project as steelwork lends itself to flexible design and a job where loadings were also likely to fluctuate.

Included in the structure is a gas-fired Combined Cooling Heat & Power (CCHP) plant to capture the heat generated by electricity production. It also includes biomass-fired boilers using sustainable biomass fuels (woodchip) to generate heat and deliver low carbon energy. Cooling is provided through a combination of electric, ammonia based chillers and absorption chillers which are driven by heat recovered from plant in the Energy Centre.

With so much large equipment installed inside the Energy Centre, and the likelihood of further items of power generation to be added, the two-storey steel frame is heavily loaded. Larger section sizes than normal were specified to take these parameters into account.

A lot of emphasis has been placed on the architectural design to ensure the Centre fits in with the wider Olympic Park. A key element of the ODA brief was that the facilities should add to the design legacy of the Olympic Park, and contribute strongly to the developing urban character of the Lea Valley as a whole.

Reflecting the heritage of the surrounding Victorian buildings also played a key role in the design as well as drawing inspiration from iconic London power stations such as Bankside (now the Tate Modern) and Battersea power station.

A structural steel tonnage of 500t was needed to erect the two-storey Energy Centre which also includes a 45m-high flue extractor tower.

As well as a very tight programme, in which to complete the project, the steelwork contractor, TAAG, had to contend with a very confined site.

“The project’s footprint is hemmed in by railway lines and a large water main,” says Kevin Nickson, TAAG Project Manager. “This meant we had to carefully plan in advance where our crane and cherrypickers could be located.”

During its three week programme TAAG used a small mobile tower crane for the majority of its steel erection, as no single piece was heavier than 5t and this crane was easily manouevred around the site. When it came to putting up the flue tower, the company had to use a 62m reach access unit.

As well as steel erection, TAAG also installed 3,500m² of concrete planks to form the floors and roof of the Energy Centre.

“Designing the flue tower required a lot of design studies to determine its constraints and possible movement,” adds Mr Papastylianos. “This was particularly relevant when designing the tower’s secondary steelwork which carries the cladding system.”

The Olympic Park’s Energy Centre actually consists of two further buildings, an electricity sub-station and a retained Edwardian building which will be linked to the main energy centre via a bridge carrying pipework.

Within the early Nineteenth Century retained façade, and also giving it stability, a new two-storey steel frame has been inserted. As well as accommodating further power generation equipment, this building will also house a visitor’s centre in the future.

ODA Chief Executive David Higgins said: “The opening of the Energy Centre was a significant milestone for the Olympic Park and demonstrated the sustainability features that underpin this project. The Energy Centre will deliver essential services throughout the Olympic Park well before the Games begin and ensure a lasting legacy of green power for generations to come. The delivery of this facility is a considerable achievement and sets a model for future urban regeneration schemes.”

Another similar energy centre has been constructed on the adjacent Stratford City development, supplying the power for Westfield’s large retail site. Both projects deliver new operational benchmarks for power generation and meet the client’s plant, maintenance, durability and expansion requirements.

Situated at opposite ends of the Park, both energy centres will act as signposts to the London Games’ site. The Olympic Energy Centre, is easily viewed from Victoria Park and all routes coming from the west, while the Stratford City Energy Centre will be easily seen from the surrounding eastern suburbs and transport links.