Projects and Features

Intumescents reducing developers’ costs

Nick Barrett reports from a London seminar which launched the new design and contractual guidance for offsite application of intumescent coatings.

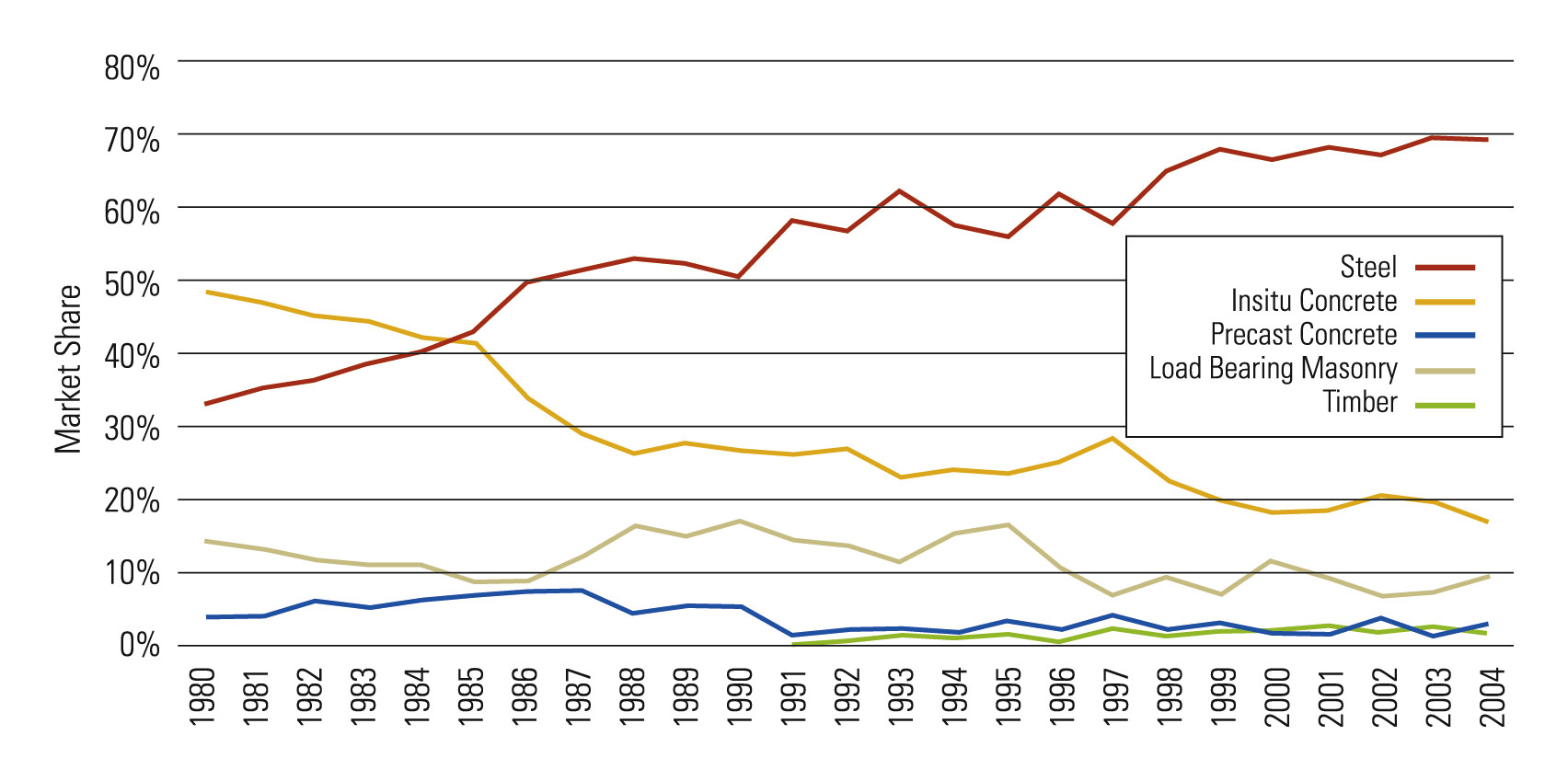

One of the big development successes of the past decade has been the growth in demand for offsite application of intumescent coatings. As recently as 1996 when the first edition of the offsite applied intumescents guide –Structural Fire Design: Offsite Applied Thin Film Intumescent Coatings – was published there was little offsite application to speak of. However a few pioneers were beginning to prove that it could be scaled up for large projects with significant savings in terms of the construction programme and quality of application. Now, over 50% of multi-storey fire protection in London is offsite applied intumescent coating.

Seminar Chairman John Dowling of Corus Construction and Industrial said some 75,000 tonnes of structural steel had intumescent coatings applied off site in 2004. The popularity is mostly a southern and south east phenomenon. ‘There is lots of scope for increasing market share in the north where only about 7-8% is offsite applied,’ said Mr Dowling. ‘The total market share is about 23%.’

The updated model specification is a new edition of SCI P160, launched by the Steel Construction Institute as the old one has been overtaken by the rapid success of offsite intumescents. Dr Ian Simms of SCI explained that the new guidance has been designed to more accurately reflect current standards, procedures and expectations of the structural steelwork industry. He said the first edition provided a new industry standard for the use of offsite applied intumescent coatings, and by presenting a model specification it was hoped that greater uniformity could be achieved in contract specifications.

In 1996 coatings were thicker, and bigger sections were sometimes specified to allow a thinner coating to be used. There have been significant advances in the technology since then, however, and coatings have been on a trend towards thinner and cheaper.

Barry Dobbins, Senior Associate Director of Waterman Partnership, told the seminar that most of his firm’s projects involved offsite application. A composite steel frame with intumescent fire protection is the preferred choice for most developments with a high degree of services coordination, he said. Maximum use of offsite fabrication processes had to be used to optimise on the construction programme. ‘The use of intumescents externally can assist in the expression of structural form. The structure can be integrated into the cladding zone. It can allow incorporation of a diagonal structure into a façade, for example. Internally it can be just as effective.’

Other benefits for developers included reduced construction cost, reduced frame size, reduced cladding and reduced fit-out costs. In sum, a better return on their investment for developers.

Clive Newman of Fire Safety Engineering Consultants said intumescents were originally developed in China in ancient times and were pioneered in the UK in the 1970s. The success of offsite application was virtuous circle, where growth in the market provided opportunities to develop better materials which in turn prompted more market growth.

Ian Wells, Commercial Director of Site Coat Services, said his company only does offsite application. On-site application should be executed by skilled craftsmen but in the wrong conditions the coatings could fail. Quality was more easily assured when application was in offsite factory conditions.

The guide is available to download as a Word document from www.steelbiz.org