Projects and Features

Furnace ready for blast off

Modular off line construction of large steel components is playing a central role in Tata Steel’s multi million pound project at Port Talbot to rebuild a blast furnace. Martin Cooper reports.

FACT FILEBlast Furnace No.4 rebuild, Port Talbot steelworks

Main client: Tata Steel

Principal contractor: Tata Steel

Designer: Siemens

Steelwork and prime contractor: Rowecord Engineering

Steel tonnage: 2,500t

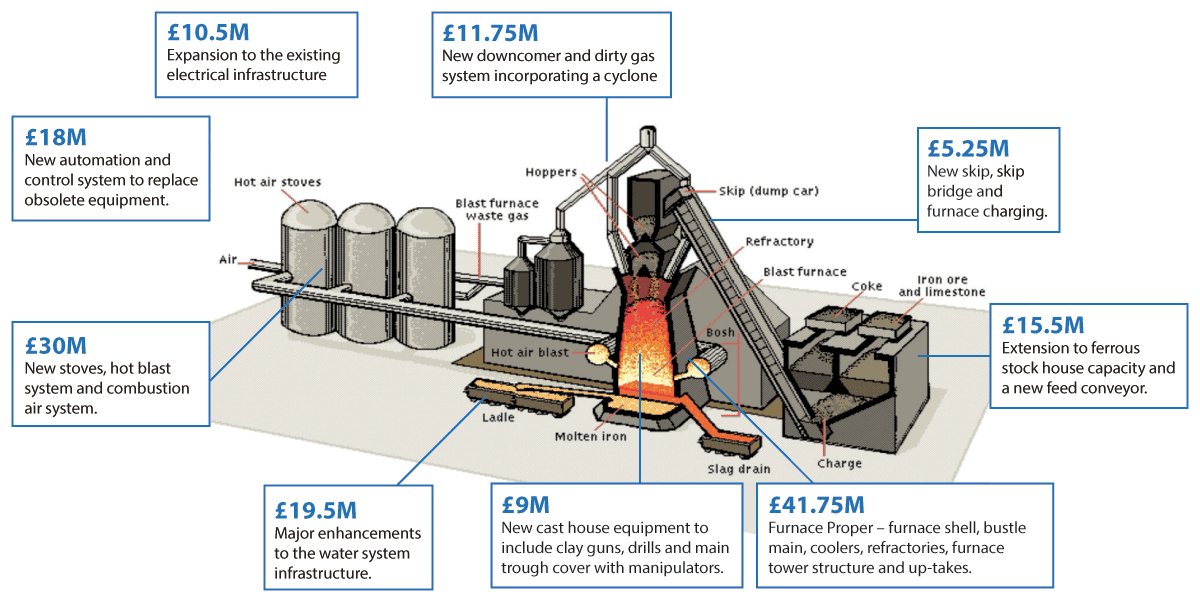

Tata Steel is investing £185M to rebuild blast furnace No.4 at the Port Talbot steelworks. The project will not only safeguard the industry in South Wales, but it will also increase capacity as the new blast furnace will have a number of enhanced safety, efficiency and environmental features.

A blast furnace is the iconic structure that defines the steel industry. It is a vessel into which raw materials are charged with the furnace reaching temperatures of over 2,000 degrees celsius. From the furnace pure molten iron is conveyed to the steel making plant around the clock.

The furnace will be CE Marked and because of its location it is apt that steel construction should be taking the lead on this huge engineering project.

There have been a number of furnaces at Port Talbot in the past and the current units are known as No.4 and No.5, dating back to 1992 and 2002 respectively.

Furnaces nowadays have a campaign life of approximately 15-20 years and No.4’s operating life has been carefully nurtured to extend it to 20 years. Initially it was planned to reline the furnace, but a few years ago the decision was taken to request investment to rebuild it completely.

Work on site began in earnest earlier this year with the shutting down and dismantling of the old No.4 furnace. The substructure and lower supporting columns were left in position and have subsequently been integrated into the new structure.

While this planned 130-day dismantling and construction programme is ongoing, Port Talbot steelworks has only one operational furnace. With 50% of the Works capacity shut down, getting the new blast furnace up and ready as quickly as possible is vital.

“The new furnace will not only restore our Works to full capacity, it will actually increase capacity by up to 500,000 tonnes a year due to its new design,” explains Tony Thomas, Tata Steel Rebuild Manager.

Most of the project team for this job were in place for the previous furnace rebuilds in 1992 and 2002. A lot of experience has been gained from those projects as Mr Thomas adds: “We’ve refined our construction methodology and learnt important lessons from those jobs which has helped us immensely.”

During July and August the dismantling of the old No.4 blast furnace was completed and the thousands of tonnes of steelwork from this structure are being recycled by going back into the steel making process.

Civil works on the retained furnace foundations were then carried out before the steelwork for the new blast furnace shell and its surrounding and supporting tower structure could be installed.

All of the new blast furnace’s steelwork has been assembled offsite into modules, which were then lifted into place in a series of heavy lifting operations.

“We used modular off line construction on the previous furnaces, but we have further developed and fine-tuned the procedure working closely with Siemens and Tata Steel,” explains Ian Hoppé, Rowecord Engineering Contracts Director.

“The modular approach was chosen to provide a reduced build time, improve the quality of the work and to allow the follow on trades to complete their work off line.”

The steelwork modules were being assembled and kitted out with ducting, pipework, cladding, electrics and other ancillary equipment while the dismantling process was being undertaken. This ensured they were ready to be installed as near complete units, almost immediately after the old furnace was gone.

Space is at a premium at Port Talbot so modular elements had to be assembled at numerous points around the site

The Port Talbot steelworks cover a vast site. However, because of the nature of the industry, the site is busy and there is very little unused space. This has meant the project’s steel modules have had to be erected and assembled at a variety of locations all over the steelworks’ site.

“Basically on any available space,” says Mr Thomas. “Once temporary foundations were in place the modules were erected and then transported to their final position by self propelled mobile transporters (SPMTs).”

The longest distance any module was transported was three quarters of a mile. Moving each of the modules to site and then lifting them into place was usually completed in one day. The site is a 24 hour working environment and lifting and transporting could take place at any time. However, the project team always endeavoured to transport modules outside of the busy shift change times.

The furnace structure modules are typically based around 18.175m column centres, with the heaviest unit weighing in at more than 505t.

The modules all vary in height and weight, depending on their final position within the project and how much pipework and equipment was installed. Rowecord has fabricated much of the installed pipework from plate, as the diameters required are so large that no tubes of this size are readily available.

All connections between each module and the interconnecting pipework are welded onsite.

Because of the size of these units, a giant 1,600t capacity crawler crane was used for all of the project’s heavy lifting operations. The crane was delivered in numerous truckloads and took several days to assemble.

The entire furnace structure consists of ten modular elements. This includes four main sections (with lift weights of 505t, 295t, 342t and 377t) and six ancillary pieces. These include the topmost part of the structure known as the ‘Breeches & Candlesticks’ and the skip bridge, a large sloping trackway leading to the furnace’s top that allows carriages to tip raw materials into the furnace.

The 700t furnace shell, when complete, stands at 39m tall with a maximum diameter of 12.7m. It comprises of a top cone and 13 tiers of plate rings, varying in thickness from 25mm up to 90mm. Each ring was delivered to site in either six or eight segments, depending on diameter and weight. The steelwork at this part of the project was manufactured at Tata Steel’s Workington facility.

On delivery, Rowecord welded the segments into tiers and assembled the tiers into three modules, giving lift weights of 402t, 143t and 161t. The modules were fitted out with safety decks and a gondola in the assembly area to allow for refractory bricking.

As well as the furnace itself, the project also includes a number of other connected parts, all of which have been completed with steelwork.

Rowecord has been responsible for dismantling the old gas cleaning plant and fabricating and erecting a new one. The new gas plant comprises a state-of-the-art vertical cyclone vessel, standing 24m tall with a diameter of 6.5m, and a scrubber vessel standing 32m tall with a diameter of 8m. Installation of the gas plant was carried out via nine module lifts, to complete this 1,500t element of the works.

A new stockhouse for raw materials has also been supplied and erected, a structure incorporating bunkers, hoppers, tipper cars and a conveyor system. This part of the project alone has required 1,650t of steelwork.

In addition, a new 43m high stove, with a diameter of 8.6m, has also been erected. “Due to the highly restricted footprint, the stove could not be erected conventionally with a crane, it was jacked up tier by tier,” explains Mr Hoppé. “We have two more stoves to dismantle and replace over the next 18 months.”

The new blast furnace is due to be up and running by the end of December, increasing the steelworks’ capacity and competitiveness.

Summing up the project, Dr Karl Köhler, CEO of Tata Steel’s European operations, says: “The investment will not only make this Welsh steelworks one of the most competitive steelmaking operations in the EU, but it will also provide a strong foundation for the whole of UK manufacturing through the supply chains this location serves.”

Testament indeed to a project that has been heavily reliant on the UK’s highly innovative steel construction industry.