50 & 20 Years Ago

40 Years Ago: An architectural expression of structural steelwork with no conventional fireproofing

Taken from Building with Steel

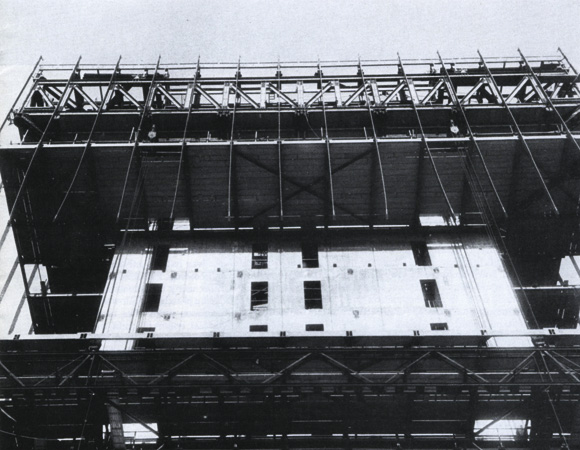

The exterior columns are connected to the main structure at every third floor, creating a series of 3-sto- rey buildings, each with its own framing, resting on the column connections.

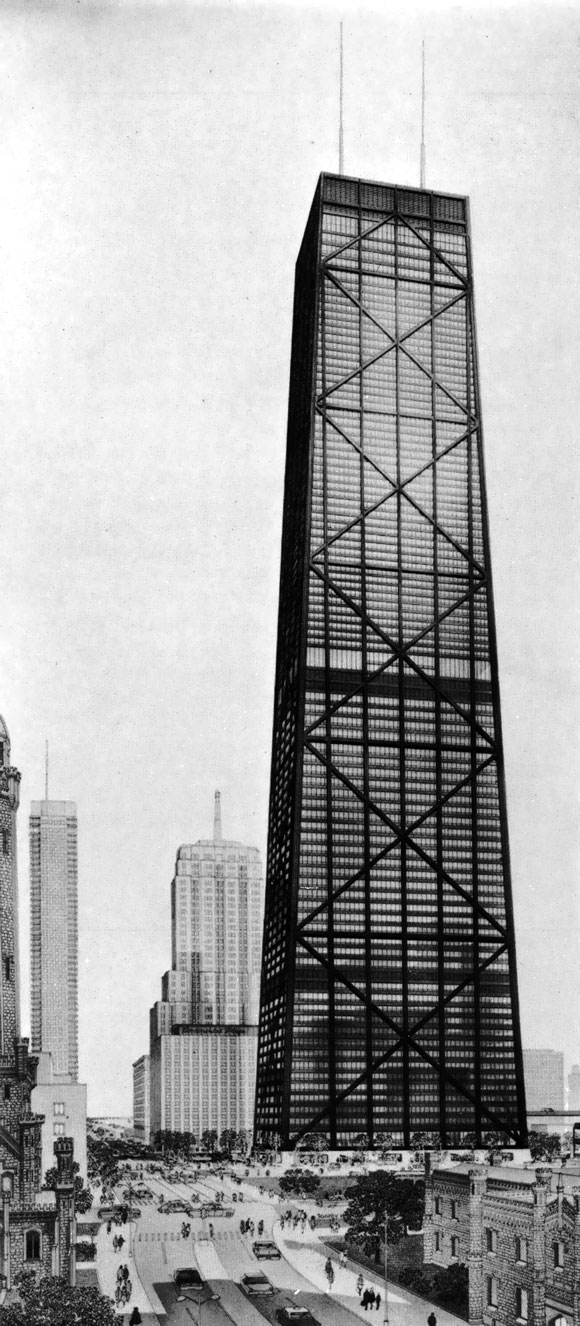

The bare and basic facts of this building are that it is triangular with 18 exposed supporting steel columns in weathering steel – six for each side – standing out three feet from the building wall. The core of the building is an equilateral triangle with sides 162 ft long. Inside the structure, which covers nearly an acre per floor, there are three rectangular office areas – resembling three separate structures sharing the same core. Each area is 221 ft long and 45 ft 6 in wide. There is a column free area of approximately 10,000 sq ft in each rectangular section.

The following statistics may be dull but they are singularly impressive – height of building will be 841 ft, single floor area 41,164 sq ft, gross area of building 2,900,000 sq ft, number of floors 64, lifts 54, elevators 9, windows 11,000.

Some of the innovations which are of interest to structural engineers are as follows:

Structural frame. The braced core works integrally with the exterior columns through a space frame (hat) at the top of the building which results in greater structural economy. The floors are attached to exterior columns every third floor, thus eliminating spandrel framing and heavy connections to these columns on two thirds of the floors. The two floors in between are supported by 2-storey high columns resting on the floors attached to the exterior columns.

Artists conception shows how the heliport which is to be built at the top of the building may look. Designed for fu- ture possible use by vertical take-off aircraft, the heliport will be used initially by conventional helicopters.

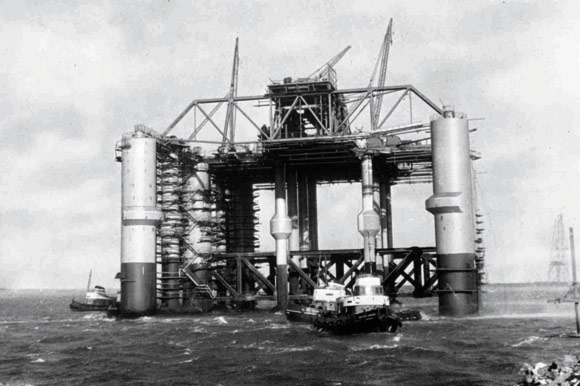

Columns. Exterior Cor-Ten columns – 36 in deep, 24 in wide – are free of conventional fireproofing and are positioned 3 ft in front of the building wall, thus providing an architectural expression of steel structure. These box columns are

fireproofed by filling with a treated water solution that circulates without mechanical aid if fire should occur. Approximately 500,000 gallons of fireproofing liquid will be in the columns. These columns are divided into four vertical zones, each approximately 200 ft high. In each zone – containing the 1⁄4 segments of each of the 18 columns – a piping system with inlets at the top of the chambers, outlets at the bottom, interconnects the columns and a 2,000 gallon treated water tank. Each zone contains 125,000 gallons of this liquid. Storage tanks are located on the 16th, 34th, 50th and 64th floors.

Exterior columns are being fabricated from Cor-Ten plate, varying in thickness from 3⁄4 in to 4 in and with a high yield stress of 50,000 lb/sq in.

Modular system. The total modular (4 ft 4 in square) system with constant dimensions from the core wall to the outside wall, 45 ft 6 in (101⁄2 modules) – together with related mechanical and electrical systems – provides the possibility of relocating partitions without altering lighting, air conditioning, architectural finishes or typical structural elements. For the office floors the floor-to-floor height is 11ft 10 in and the floor-to- ceiling height is 8 ft 6 in.

Curtain walls for cladding the building will be constructed of weath- ering steel that turns to a deep russet colour when left exposed to the weather, and never needs painting.

Exterior walls. Cor-Ten steel wall framing with horizontally pivoted stainless steel windows is to be used for the exterior wall. The vertical mullion will have a 51⁄2 in depth and will frame the 6ft high by 2ft 4 in wide windows. The panel area between the vertical lines of windows will be 2 ft wide by 32 ft high. Each window and adjacent panel measures 4 ft 4 in which corresponds to the interior office module.

A very significant innovation comes under the heading ‘Heliport’. Design is adequate to accommodate vertical take off aeroplanes in accordance with data furnished by aircraft companies. They indicate that these aircraft will be used in the next few years. Conventional helicopters will use the heliport in the meantime. One of the architects of the building has stated that in collaboration with engineers, all types of plan form were studied and analysed before the triangular plan was finally adopted.

He says that the triangular plan is amazingly efficient as a structure, the form most fitting to the functional requirements of a major high rise building. The basic structural and wall elements are articulated clearly and produce an interesting play of form and shape, displaying the vitality of the structural system. “We feel we have a building which illustrates the excitement and glamour of steel.”

Architects: Harrison & Abramovitz & Abbe;

Structural engineers: Worthington, Skilling, Helle & Jackson.