Projects and Features

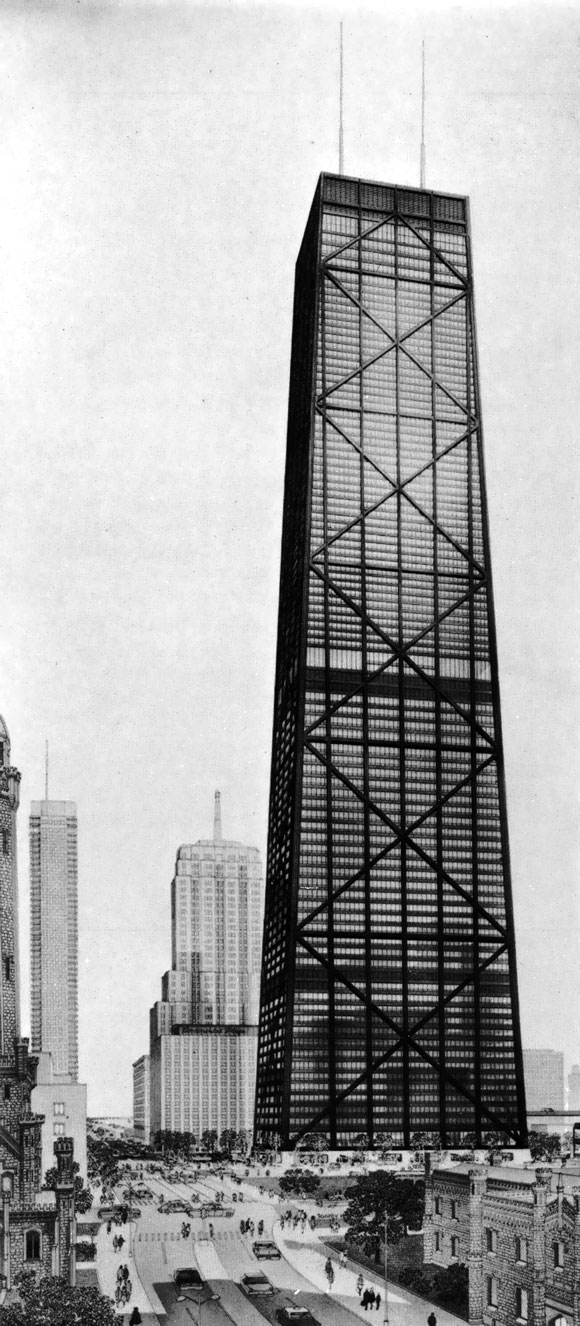

40 Years Ago: The world’s tallest residential-office building begins to climb

Taken from Building with Steel, 1968

The John Hancock Centre in Chicago has to climb to a height of 1,107ft above ground level before it is complete and stands, a giant on a two acre site – see left for a lilliputian’s conception of its stature. Salisbury Cathedral spire soars to 404ft and that used to be considered tall!

This journal is vitally interested in the architectural structure about which the following information has been released:

A tower tapering on all four sides, from 50,000 sq ft at the base to 16,000 sq ft at the summit.

Exterior

The exterior appearance will feature a structural steel frame clad in black and bronze aluminium and bronze-tinted glare reducing glass.

Structure

The structure will be an integral part of the exterior, with diagonals providing stability and strength.

The Centre will afford the most economic space in steel construction: in effect it will be a bridge type structure consisting of a trussed box. The twofold use of the building for public and residential needs will create an architectural landmark, alive an in use 24 hours a day.

Steelwork facts

Tonnage – 42,000 tons: site connections (a) Weld metal 165,000 lb total: (b) Bolting – 105,000 high strength bolts: height of structural frame, 1,125 ft from top of base plates to top of roof: taper – for each 100ft of height the sides taper in 5 ft, the short sides 3 ft.

Erection – basement to 6th floor – crawler crane: 6th floor to 76th floor – 4 stiffleg derrick creepers: 76th floor to roof – 2 stiffleg derrick creepers.

Scheduled time to erect structural steelwork – 16 months.

Base plates – 12 in thick – 7 ft 10 in by 7 ft 10 in. weight – 15 ton max: exterior plates set out of level (perpendicular to column): 2-in dia. anchor bolts. Maximum Creeper lift – 38 tons.

Column tiers extend for 2, 3, and 4 floors: 15 tons of erection bracing are required at each working location. Each creeper receives steel at ground level and hoists its own steel, the receiving areas decreasing as Creepers ascend the building.

Creeper connection to permanent structure – 2-in thick hitch plates are welded to the outside face of columns, the welding of column plates being extensively tested. The creeper support platform is connected to column plates by using two 41/2 and two 5-in pins.

Exterior framing weights – (a) horizontal ties – max weight 1,735 lb per ft; (b) diagonals – max weight 1,779 lb per ft; (c) columns – max weight 2,859 lb per ft; (d) gusset plate complex at building corners have max weight of 33 tons. Crawler cranes will erect creepers complete.

Lifting with derrick creepers, normally a bridge building technique, was decided upon because all the walls of the centre taper inwards.

Orthodox cranes atop the rising building would have required enormously long booms to reach out beyond the slope of the structure and pick up their loads of steel from the ground.

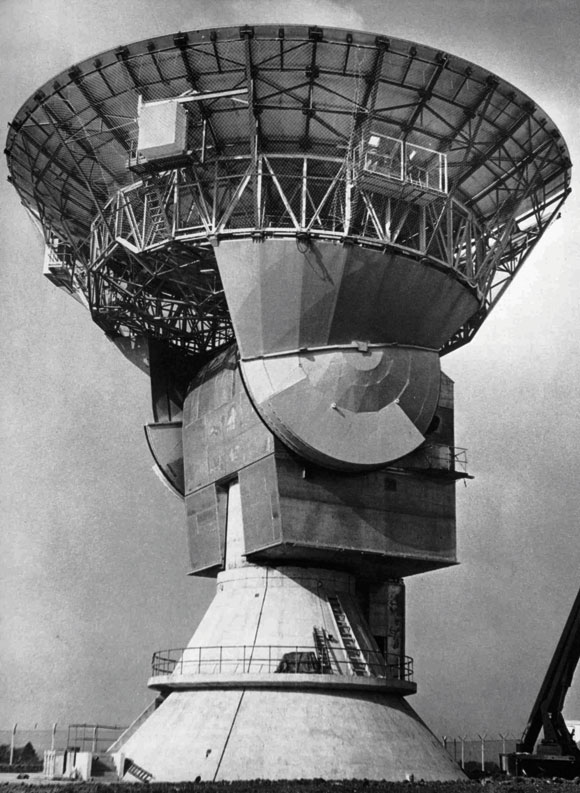

Each creeper consists of a support platform, a tower and a stiffleg derrick with a 105-ft boom. The rig is 110 ft tall, not counting the boom. The entire unit fits to the side of the building, fastened securely in place with high strength connecting pins (see bottom photo).

The creepers began their work after they were installed at the 6th floor level (ground cranes handled steel up to that height). Their booms are long enough to permit erection of three floors of steel before the next three storey upward ‘jump’ is made.

Powerful electric hoists pull the cranes up to each new position. A system of guide beams and rollers ensures smooth travelling.

The time needed to hoist a fresh load of steel from the ground to the topmost construction level will increase to a maximum of about 10 minutes when the job nears completion.

Creepers climbing up the east and west sides of the Centre will be hoisted 31 times. Those on the north and south faces will be raised 21 times. At the 75th floor the north and south cranes will be removed. The east and West creepers will complete the job after they have been equipped with longer 120-ft booms.

The heaviest steel members in the structure are the four corner columns which reach from the basement to the second floor. Only 39ft long, they weigh 100 tons each. They were erected by crawler cranes.

Architects – Skidmore, Owings and Merrill.