Projects and Features

Up, up and away

Once Watson Steel had fully erected the intermediate tower, it then installed the cable car running gear.

The first of three signature towers for London’s newest river crossing has been fully erected.

NSC embarks on the Emirates Air Line.

FACT FILE - Emirates Air Line

Architect: Wilkinson Eyre

Main contractor: Mace

Structural engineer: Buro Happold

Steelwork contractor: Watson Steel Structures

Steel tonnage: 1,150t

A new and iconic addition to the capital’s infrastructure is under construction in east London. The Emirates Air Line will be the UK’s first urban cable car and form a vital link across the River Thames with a capacity to carry up to 2,500 passengers per hour in each direction.

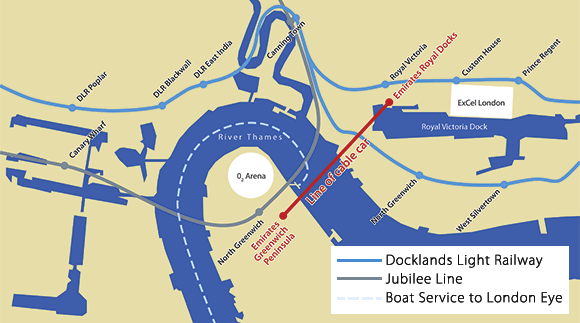

The cable car will stretch across the Thames between two terminals, one in North Greenwich, home of the O2 – Europe’s largest entertainment venue – and the other at the Royal Docks on the north bank, which is the location of the Excel conference and exhibition venue.

The number of passengers using the link will be equivalent to the hourly number of people travelling through the Blackwall Tunnel

Three steel towers will support the Emirates Air Line, one on the south bank and two on the north shore, including an intermediate structure. Last month (January), the North Intermediate Tower was the first to be fully erected. Although the smallest tower it still stands at over 65m tall and weighs more than 290t. The other two towers will top out at 90m and weigh in excess of 550t each. All three towers are due to be erected by late spring.

The first tower was built within days of its steel pieces being delivered to site. Every piece of steel for the project is being fabricated in Bolton by Watson Steel Structures. Over half of the two hundred employees at the factory are dedicated to this project and will continue to be until the last piece is manufactured.

As all of the towers are similar, the design, fabrication and erection of each structure will be the same. Innovation has been at the heart of the design and construction of the Emirates Air Line with the latest methods and technologies used to create this unique addition to London’s transport network. Watson Steel planners took the design for each of the towers and using cutting-edge 3D modelling created the accurate templates for each piece. This intricate modelling saw designs for each part drawn to within a millimetre to ensure every piece fits together like a jigsaw.

“Tower sections with a diameter of less than 4m are delivered to site fully complete,” explains Peter Miller, Director at Watson Steel Structures. “Above this size and up to the largest 10m diameter sections for the bases, these are fabricated and delivered in halves and site welded before being erected.”

All of the tower sections are lifted into place by crane, a 500t capacity mobile crane did the intermediate tower, while a 1,200t capacity crawler is being used for the southern structure. Once each tower section is lifted into place they are bolted to the steelwork below via an internal flange plate.

Worker access for the bolting up is from the inside of the tower, which negates anyone working on the outside of the tall structures. “During the design stage we had to take the erection sequence into consideration and as the towers will have permanent access for passengers we’ve used this as temporary access for our erectors. All of the splices have been designed to correspond with internal platforms,” explains Mr Miller.

Each tower will be made up of hundreds of separate pieces of steel plate that vary between 10mm and 50mm in thickness. A complex helix like structure, which has been specially designed for the inside of the towers, will provide the strength and stability needed to transport the thousands of passengers up the towers every hour.

Much of the steelwork is being fabricated in sections that can be delivered to site and then erected immediately.

The helix structure is already fully assembled inside of completed tower sections, but for those that need to be site welded, the helix is delivered as individual elements along with four separate ‘ribbons’ that form the vertical part. These complex pieces of steelwork are compound sections of tubular and flat plate which were doubly curved during fabrication.

The completion of the first tower comes as the Emirates Air Line achieved another first – appearing on the internationally renowned London Underground Tube map. It is the first time in the Tube map’s 78 year history that a commercial brand has been able to put its name to a transport link and station as a result of a partnership with TfL. The map also highlights how the new scheme will integrate into the wider transport network by providing an additional step free access interchange between the Jubilee line and the DLR – two key lines in east London.

Mayor of London, Boris Johnson, says: “The Emirates Air Line is a vital part of the regeneration of east London, providing a much needed river crossing in this part of the capital. Investment in infrastructure such as this is essential for London’s economic recovery, generating jobs and showing to the world that this city is looking to the future with vision and confidence. It is also showing off the ingenuity of the UK firms that are crafting these magnificent towers.

Danny Price, TfL Emirates Air Line Operations Manager, says: “The completion of the first tower for the Emirates Air Line is a major milestone in the project and helps everyone to visualise how unique and exciting London’s new travel experience will be. I look forward to seeing the other graceful towers rise up over the next few months. It’s a great source of pride that this crucial job is being carried out in the UK, providing a brilliant example of the best of British manufacturing.”

The Emirates Air Line will provide a new river crossing for east London, a key objective for the Mayor to help unlock further the economic potential of this part of the Capital. The scheme supports the Mayor’s vision to transform this area into a bustling metropolitan quarter with new businesses, homes and job opportunities. It will also draw tourists from across the globe adding to the ongoing regeneration of east London.

Once the towers have been completed, Watson Steel also has the steel erection of the two terminals to complete as well as a gondola storage building to be located close to the south station.

The Emirates Air Line is due to open later this summer.