Projects and Features

Tata Steel proves ‘Very Good’ responsible sourcing

Tata Steel can prove its raw materials are sourced from suppliers with high environmental procedures in place

Tata Steel’s UK manufactured products have achieved BES 6001 ‘Very Good’ providing proof that they have been responsibly produced.

Construction industry clients are increasingly asking suppliers to prove that their products have been responsibly sourced.

Main contractors, architects and engineering designers are in turn asking their supply chains probing questions about this vital element of sustainability, and the onus is on manufacturers to prove that their products have been responsibly produced and their constituent materials responsibly sourced.

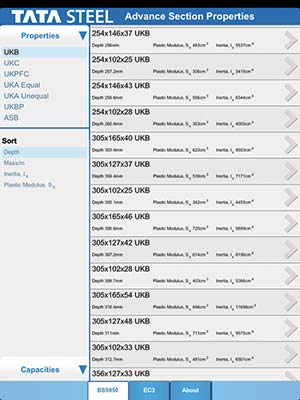

All of the responsible sourcing questions can be answered with confidence for steel construction using Tata Steel products manufactured in the UK, thanks to the company’s pioneering efforts in becoming one of the largest companies, with a very complex supply chain, to have achieved certification to BRE’s sustainability standard, BES 6001. Designers can specify Tata Steel products with confidence that they are now certified ‘Very Good’ under the standard. The certification includes all structural products such as Advance steel sections, Celsius structural hollow sections, RoofDek and ComFlor decking, and also covers building envelope products such as Trisomet, Trimapanel and Catnic building products. Colorcoat branded products from Tata Steel, Colorcoat Prisma and Colorcoat HPS200 Ultra, have been certified to the standard since 2010.

Colorcoat products manufactured at Tata Steel’s Shotton plant were the first BES 6001 certified pre-finished steel manufactured products available to the market.

A major plus for developers and builders of steel framed buildings is that BES 6001 provides, at no extra cost, a route to obtaining the maximum number of credits available in the Responsible Sourcing of Materials section of BREEAM for materials that are not being re-used. They can also assure their clients, who are looking for independent third party certified assurance, that the supply chains they are using are responsible. Products certified to BES 6001 are made in facilities pursuing environmental programmes covering, amongst other things, greenhouse gas emissions and waste reduction. Moreover, BES 6001 requires that the constituent materials in construction products have been traced to known responsible sources, in the case of steel, as far back as the point of mineral extraction.

Government funded projects in the near future will increasingly demand the use of BES 6001 certified products and private developers are keen to show their commitment to sustainability, so Tata Steel is providing its own customers, mostly steelwork contractor members of the BCSA, with a competitive lead as the insistence on using BES 6001 products grows.

Achieving responsible sourcing certification might be relatively straight forward for some construction products, particularly those that use only local materials, but for a major, integrated multi-national steel manufacturer like Tata Steel, supplying a wide range of construction products, the task is of a greater magnitude than has been attempted before.

Tata Steel Europe Head of Environmental Policy and Strategy, Peter Quinn said achieving the certification over a six-month period has been a highly complex task that has involved a multi-functional approach within the company.

“Tata Steel is leading the way with responsible sourcing and takes its environmental and social responsibilities very seriously. It is not always easy to validate green credentials, but BES 6001 is an independent standard recognising companies that go that step further to achieve sustainability. The standard not only assesses the sustainability of our own operations, it also requires us to demonstrate confidence in the responsibility of our raw material suppliers as far back as mineral extraction.”

Tata Steel’s certification helped Speller Metcalfe achieve the highest BREEAM ‘Outstanding’ rating in the world

This is a particularly onerous task for Tata Steel as its predominant raw material, iron, comes from a number of sources globally, in the form of iron ore fines, lump and pellet as well as scrap. In the case of ore, this is brought into the UK via a number of ports and then travels on to integrated steelworks to be made into steel. Extensive calculations were carried out to determine the contribution of each source of supply to an average tonne of construction steel. From this Tata Steel was able to prove that 100% of traceable materials came from suppliers with high standards of environmental stewardship, human rights adherence and health and safety management.

Having assessed the raw material supply, the next area of focus was on Tata Steel’s own internal policies and processes.

Mr Quinn continued: “The auditor from BSI had access to the robust environmental, quality and health and safety management systems we have had in place, albeit subject to continuious improvement, for many years. This helped us hugely in securing certification, and indeed there was no need to introduce any new management systems.”

Tata Steel has a comprehensive range of sustainability related policies and practices in operation across all of its plants and operations. Underneath a comprehensive policy framework setting out its commitments, and the management systems described above, it has implemented processes such as a new energy efficiency governance mechanism across its operations, investments to ensure compliance with government zero waste policies, strategies for monitoring and reviewing water use, policies to reduce transport impacts, a focus on the health and safety and the skills development of employees, and a company-wide focus on having a positive impact on their local communities.

Kids of Steel, part of Tata Steel’s Community Partnership Programme, has given nearly 60,000 children the opportunity to have a fun, positive experience of sport.

Mr Quinn added: “What it all means is that when our customers ask us questions about responsibility in the supply chain and our own manufacturing systems we have strong, independently verified proof to back up our answers.”

Jonathan Clemens, Tata Steel’s Head of Marketing, Construction & Infrastructure, said: “Having our construction products certified to BES 6001 enables us to benchmark our sustainability performance in the construction sector and demonstrate that we are continually improving in this area. We now supply the widest range of construction products certified to BES 6001 and in the case of certain construction products, such as Celsius structural hollow sections and ComFlor composite floor decking, we are the first company to have acquired this certification. As a result, more than any other steel supplier, we can offer specifiers, contractors and building owners the reassurance they need when meeting the UK Government’s requirements for sustainable development. Many of our customers will be on their own journeys towards achieving BES 6001 and they will be reassured to learn that we have already done much of the hard work for them.”

To obtain a copy of Tata Steel’s certificate please email construction@tatasteel.com

or call +44 (0)1724 405060

The responsible standard

BES 6001 has been developed by BRE to enable construction product manufacturers to demonstrate their commitment to sustainability. Responsible Sourcing of Construction Products is described by BRE as providing a holistic approach to managing a product from the point at which component materials are mined or harvested, through manufacture and processing.

BES 6001 has been developed by BRE to enable construction product manufacturers to demonstrate their commitment to sustainability. Responsible Sourcing of Construction Products is described by BRE as providing a holistic approach to managing a product from the point at which component materials are mined or harvested, through manufacture and processing.

The standard provides a framework for the organisational governance, supply chain management and environmental and social issues that need to be addressed for construction products to be properly regarded as having been responsibly sourced.

BES 6001 provides an independently assessed standard demonstrating a specific level of sustainability performance, making it one of the key ways that manufacturers like Tata Steel can validate their sustainability claims.

Responsible sourcing is demonstrated through an ethos of supply chain management and product stewardship encompassing social, economic and environmental dimensions – it is the Triple Bottom Line of sustainability applied to responsible sourcing.

The certification process involves looking at stakeholder engagement, labour practices and the management of upstream supply chains. Requirements of certification include organisational management, supply chain management and environmental and social issues. Some elements must be satisfied for any certification to be granted, and higher levels of compliance can result in higher performance ratings being awarded.

Tata Steel Europe has led the way in the steel sector, with Colorcoat products manufactured at its Shotton plant being the first BES 6001 certified pre-finished steel manufactured products available to the market. Initial certification was secured in 2010 and they have since been recertified to a ‘Very Good’ rating in 2011, 2012, and 2013.

BREEAM and the Code for Sustainable Homes grants extra credits in their assessments for products that achieve BES 6001 ‘Very Good’ or ‘Excellent’ ratings.