Projects and Features

Steelwork completes full circle

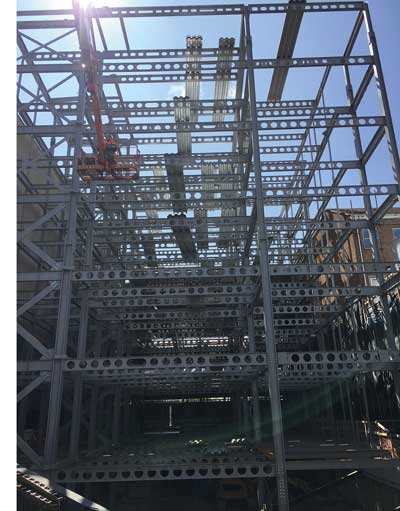

A 15-storey steel-framed speculative office block represents the final piece of Manchester’s multi-million-pound Circle Square development.

FACT FILE

No. 3 Circle Square, Manchester

Main client: Bruntwood SciTech

Architect: Bridge Architects

Main contractor: GMI Construction

Structural engineer: Curtins

Steelwork contractor: Billington Structures

A sought-after new city centre neighbourhood in Manchester, known as Circle Square, is nearing completion as the steel frame for the final commercial scheme has now been completed.

The £750M mixed-use development offers office space, retail outlets, serviced apartments and private residential accommodation as well as a large centrally-positioned public space, known as Symphony Park.

The plot, which is close to Oxford Road station, was once the home of BBC North West, a facility which hosted the filming of many TV favourites, such as Question of Sport and Mastermind.

Today, the site is aligned with the wider Oxford Road Corridor Innovation District, which is already recognised as a leading European home for technology and research-based companies. Businesses based at Circle Square benefit from being part of this growing tech community as well as the city’s extensive network of higher education institutions, including the University of Manchester and Manchester Metropolitan University.

Known as No. 3 Circle Square, this is the fourth large steel-framed structure to be built for the scheme, following on from No.1 and No.2 Circle Square and the 1,031-space multi-storey car park (see NSC June 2019).

Targeting BREEAM ‘Excellent’ and EPC A ratings, sustainability is said to be at the heart of No.3 Circle Square’s design. Helping to reduce the embedded carbon of the project, much of the steelwork was sourced, by Billington Structures, from Electric Arc Furnace (EAF) production facilities.

Bruntwood SciTech was keen from the outset of the design process to have a significant recycled steel content within the building’s frame.

Using 100% recycled steel, instead of iron ore, EAF production is also considered to be much greener and more efficient in terms of energy consumption.

Once complete, the building will benefit from an all-electric heating and cooling system with state-of-the-art air source heat pumps, as well as smart metering, roof mounted solar panels, a smart BMS and local MVHR units to maximise efficiency and fresh air control to occupants.

“As well as offering sustainability benefits, the structure was always going to be a steel-framed building, as the material offered the quickest programme and the best way of forming the desired long internal spans,” says Curtins Director David Sandbrook.

Using the site’s two tower cranes for all lifting duties, the steel frame was erected quickly and efficiently. The erection was carried out in a sequential programme, three floors at a time.

“For the erection of the lower floors, we were able to use some of our largest MEWPs positioned at ground level,” explains Billington Structures Project Manager Russell Davies. “Further up the building, the sequential programme gave us the benefit of allowing our smaller MEWPs to be landed on the ENP-nailed decked floors.”

Creating the desired open-plan floorplates, the steel frame has perimeter columns spaced at up to 7.5m centres, while internally there are spans of up to 15.5m long. Helping to create these long spans and maximise the office floorplates, the concrete core, which provides the stability for the steel frame, is offset and located along the southern elevation, instead of having a traditional central position within the building.

Supported on piled foundations, which are up to 14m-deep, the steelwork starts at ground level as the building has no basement. The ground floor is a double-height space with a 6m floor-to-ceiling height. It accommodates a mezzanine, covering roughly half of the structure’s footprint and the reception lobby.

Located on the north-west corner of the building and directly opposite the development’s centrepiece green space (Symphony Park), the main entrance is framed by two V-shaped columns. Extending to the underside of the first floor, these feature elements divert the loads from above and allow the entrance to be column-free.

This latest addition to the Circle Square neighbourhood will pay tribute to Manchester’s Victorian and Edwardian architecture. To this end, the building will feature high quality and traditional red brick façades for the upper levels. The ground floor will have brick arches, a similar design to the adjacent multi-storey car park. The arches will be formed with precast units that will connect to brackets that have been shop welded to the ground floor columns.

Internally, the steel frame consists of cellular beams that accommodate the building’s services within their depth, and support metal decking and a concrete topping for a composite flooring solution.

Specialist firm, SMD supplied and installed 31,105m² of metal decking, which required 86,000 shear studs.

Working on behalf of main contractor GMI Construction, Billington Structures fabricated the project’s bespoke cellular beams from UB sections for the majority of the floors. The exception was the building’s uppermost two levels that have been designed to incorporate a communal lounge, event space and two roof terraces, at either end of the building. Because these features impose additional loadings, plate girders have been used for these floors.

Summing up, Bradley Topps, Commercial Director at Bruntwood SciTech, commented: “With No.1 and No.2 now fully let, and a successful consultation period complete, it’s exciting to see work progressing at No.3.

“Our goal for Circle Square has always been to provide the perfect synergy between sustainable, high quality workspaces and first-class amenities, and this latest development is in keeping with that ethos.

“Bolstering the digital ecosystem within the Oxford Road Corridor will add vital capacity to Manchester’s knowledge economy and showcase the wider region as a diverse international base for innovative science and tech firms to thrive.”

No. 3 Circle Square is due to be complete in early 2025.