Projects and Features

Steel forms City’s sustainable tower

FACT FILE

8 Bishopsgate, London

Main client: Mitsubishi Estate with Stanhope

Architect: WilkinsonEyre

Main contractor: Lend Lease

Structural engineer: Arup

Steelwork contractor: William Hare

Steel tonnage: 8,500t

An evolving design and high sustainability credentials have both been key ingredients for 8 Bishopsgate, the City of London’s latest landmark high-rise development.

Rising up on a plot bounded by two of the City of London’s busiest thoroughfares, the latest steel-framed high-rise scheme in the square mile’s eastern cluster is quickly taking shape.

Featuring a host of sustainability credentials, the EPC A rated building is set to be the UK’s tallest structure to achieve a BREEAM ‘Outstanding’ rating. With 30% less structural embodied carbon than London tall building benchmarks, 8 Bishopsgate is a stand-out development in many ways.

The construction programme for this prestigious commercial project has unfortunately coincided with COVID-19 lockdowns, which led to some uncertainty as to when office workers will return, full time, to their regular places of work.

With the onset on the first lockdown last year, many commentators were suggesting that working practices would be radically altered, with working from home becoming the ‘new’ normal on a permanent basis.

However, property analysts are now suggesting the opposite and once the pandemic is over and the vaccination programme has been widely rolled out, the commercial property sector could be set for a significant boost.

According to Savills, every survey that has been done of office workers suggests that most will continue to spend the majority of their working week in traditional offices. Coupled with an end to (or at least a diminution of) Brexit-related uncertainty in the investment market, this could all be good news for the commercial sector.

Consequently, the construction of commercial developments has continued throughout the pandemic, with a view to better times ahead. The 50-storey 8 Bishopsgate, which on completion will be the square mile’s fourth highest building, is the most prestigious office scheme currently under construction.

It will offer 52,900m² of office space in what is said to be the UK’s most sustainable commercial tower.

According to WilkinsonEyre Director Oliver Tyler, sustainability has been a key design driver from the project’s inception and one of the main goals was to achieve material efficiency.

“We’ve used bespoke fabricated steel sections throughout, which have been optimised for individual unique loads. By rationalising the building’s frame, we need 25% less steel, which saves approximately 5,000 tonnes of carbon.”

Another initiative to make sure the steel frame meets the project’s high sustainability goals is to leave the majority of it exposed within the completed structure.

“The steelwork is painted offsite and once it is erected we only need to do some minor touch-up work,” says Lend Lease Project Director Paul Gransby.

“The exposed steel frame provides the building with a modern industrial-looking office environment, but importantly we use less materials, which is good for sustainability, to enclose the columns and beams.”

As the steelwork will be on show, a lot of care was taken with the choice and design of the connections. Two splice arrangements for the columns and bracings have been used by steelwork contractor William Hare. They are: an internal splice plate connection, with countersunk bolts that minimise protrusion from the outer section diameter; and a recessed end plate connection, which butt the connecting member’s webs and flanges up against each other.

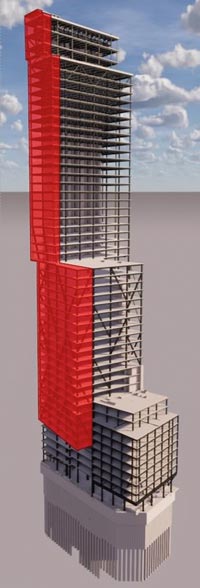

Starting at ground floor level, the steel frame incorporates three distinct blocks that are stacked-up to form the overall building.

Each has a unique identity related to the cladding module, the addition of fins to the mullions or how the structure is seen through it. While predominantly glazed in a double skin curtain walling, the lowest block is clad in stone to respond to the street level context.

The stacked design is the best shape to maximise the site’s development potential and helps the structure step-down in a southerly direction to address View Management constraints associated with St Pauls.

A low-rise block extends up to level 11, a mid-rise one, which actually sits behind the lower block, starts at sixth floor and goes up to level 26, and then a slim high-rise block tops out at floor 48. A three-storey pavilion is then positioned above this floor, incorporating a public viewing gallery and plant zones.

The primary internal grid for the low and middle blocks is based around a 12m × 9m column pattern, using 620mm-deep plate girders with circular and rectangular openings to accommodate the building services.

“The column positions have been selected in order to mitigate any column transfers, whereby the internal columns in the low-rise block continue upward to become perimeter members on the mid-rise part of the project,” explains Arup Project Engineer Jeremy Edwards.

Using the same column grid pattern, the high-rise block has no internal columns as beams span directly between perimeter steel columns and the core, creating 21-storeys of column-free space.

Providing the stability for the 50-storey building are two concrete cores. The north core extends from the basement up to level 51, while the south core terminates at level 24.

Providing some extra stiffness to the structure, the mid-rise block is a braced box, featuring perimeter steel bracing that connects the two cores together and mobilises the perimeter columns to resist horizontal loads (see box story). This stiffens up the low and mid-rise blocks and allows for a narrower north core for the uppermost block.

Helping to further maximise available floor space, the building cantilevers out along its western elevation, over-sailing the pavement along Bishopsgate.

This overhanging west face reinforces the architectural concept, while providing 15% of the Net Internal Area, thereby improving the viability of the scheme and enhancing its identity.

“For the transfer of vertical loads, the west face can be viewed as a 20-storey truss, which is supported on its north edge by a series of raking columns that connect to the north core and by a series of further columns on the southern edge,” adds Mr Edwards.

The western elevation overhang commences at level six and initially extends up to floor 26. This is the truss, and it forms a 5.5m-wide cantilever on the north, which increases to 9.5m wide at the south.

Further cantilevers begin at level 26 and 48, with the former overhanging by up to 3.8m. This feature is formed by three inclined columns, sat atop the truss and extending up to level 30 (four floors), where they are tied into the steel frame and anchored into the diaphragm.

Finally, the uppermost overhang at level 48 is created by two inclined columns, which extend up to floor 50, where they are also tied into the frame.

The stacked design also means the development has three main terraces facing south and west, at level 11, 26 and 48. Approximately 10% of the building is dedicated to shared space, both indoor and out. This includes 1,400m² of terraces, which will be adorned with evergreens and seasonal blooms.

Communal amenity space for tenants extends to a 200-seat auditorium, a double-height space that is located at second floor level.

“This is a complex area and, because of its location, we had to install a temporary logistics deck of precast planks spanning across the auditorium, which will be removed to allow the fit out to commence once the structure above is complete,” explains Mr Gransby.

8 Bishopsgate is due to be complete by the end of 2022.

Developing design

The history and evolution of the 8 Bishopsgate scheme goes back to 2015 when WilkinsonEyre won planning permission for a 40-storey centrepiece office development featuring a ‘stacked’ three block design.

“Following the approval of a number of other towers in the City’s eastern cluster that impacted on our original proposals, we submitted a revised planning application in 2017,” says WilkinsonEyre Director Oliver Tyler.

“Keeping the stacked design, which is best suited to the constrained site, our approved revised plans added 10-storeys to the tower, totalling an extra 11,000m2 of office space.”

The 50-storey tower encompasses three basement levels, ground floor retail and a public viewing gallery at its summit.

West face bracing

According to Arup, a stochastic search algorithm was used to assess hundreds of bracing arrangements on the building’s west face, with the most efficient arrangements developed further for the design.

The bracing sections span four floors and node out with the edge beams and the perimeter columns. The columns are tied into the floorplates they pass through. The stochastic arrangement utilises the diaphragm to resolve the horizontal component of the forces at bracing ends. Careful assessment has been carried out to ensure the horizontal loads generated on each braced box floorplate have been worked through and that no component is over-utilised.

The columns and bracing on this face are typically 450mm × 450mm fabricated H-sections with plate thickness ranging from 30mm to 80mm. Where larger forces exist, the section depths have been increased and in isolated locations double webbed H-sections have been used.