Projects and Features

Steel creates Cyclone

Structural steelwork is playing a leading role in the creation of a new and exciting addition to the available attractions at Center Parcs Whinfell Forest.

FACT FILE

Center Parcs Whinfell Forest, Cumbria

Client: Center Parcs

Architect: Holder Mathias Architects

Main contractor: SDC Builders

Structural engineer: Stantec

Steelwork contractor: TSI Structures

Steel tonnage: 90t

A 125m-long ride, known as a Tropical Cyclone, where thrill-seekers, sat in inflatable rafts, are transported down a flume that incorporates twists, turns and drops is currently under construction at Center Parcs Whinfell Forest near Penrith in Cumbria.

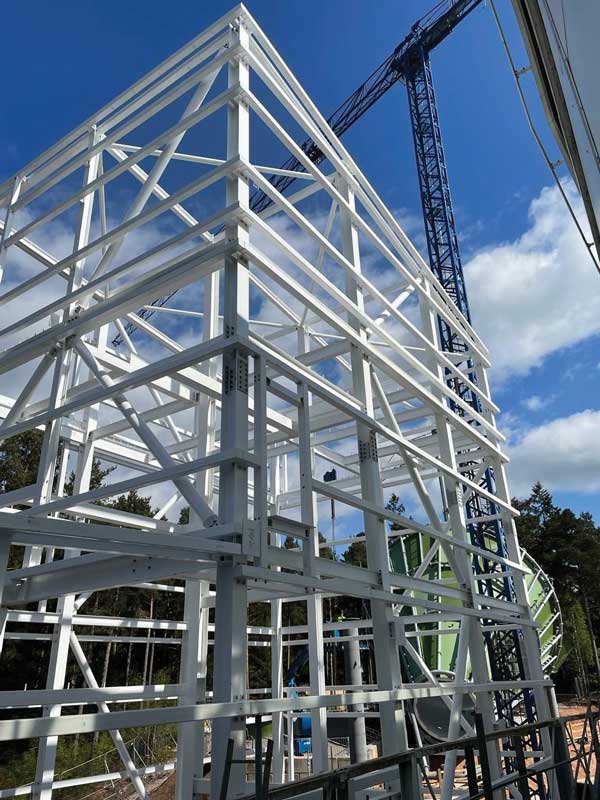

This latest attraction is being realised with the aid of steel construction, as the giant flume is supported by a steel tower, that also includes a link bridge to an adjacent Subtropical Swimming Paradise building, as well as areas for the ride’s associated plant equipment.

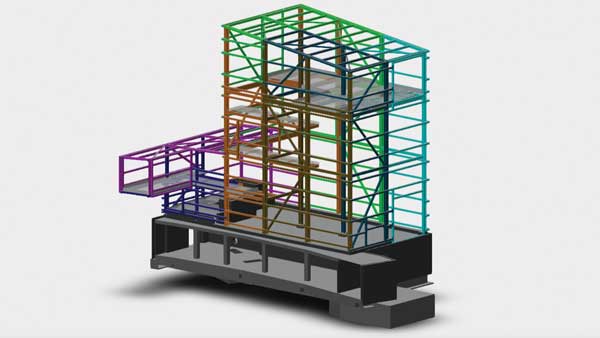

Including its plant areas, the steel-framed structure is 14.5m-wide at the base, 10m-wide at the tower and has an overall height of 20m. It is formed with 305UC columns that are connected by a series of 150mm × 150mm box section cladding rails.

A structural steel frame was the ideal choice for the project as Holder Mathias Architects’ Associate Director David Gallimore explains: “Due to the confined nature of the site, surrounded by trees and areas still occupied by guests and staff, speed and safety of construction was of paramount importance.

“Consequently, steel has been used for the structure of the envelope above the level of the concrete plant room water tanks. Meanwhile, galvanizing and organic coatings are necessary to protect the steel from the pool chemicals in the atmosphere and provide the appropriate levels of fire resistance.”

Working on behalf of SDC Builders, TSI Structures fabricated and then supplied the steelwork in small transportable loads before commencing the erection programme.

Due to the restricted nature of the site, the reduced size loads had to be meticulously planned on a just-in-time basis, which also needed to ensure there was no impact to the regular operation of the village or guest experience.

“The work site is quite confined, while access to the Center Parcs project is predominantly along small and winding roads, which are unsuitable for large trailers,” further explains TSI Technical Director Adrian Betts.

“This meant the steelwork had to be delivered piece-small, including the main 20m-high columns, which were delivered in two pieces and have a bolted splice connection.”

Hand-in-hand with the steel erection, suitable lifting locations had to be selected, which removed the need for any over-lifting or oversailing of the surrounding facilities.

“This facilitated an erection sequence to be developed by the project team that allowed the works to continue safely while the pool was in use,” adds SDC Builders Contracts Manager Mike Hodges.

Another of the main challenges for the onsite erection team was the fact that some of the steelwork was specified to be painted with Sherwin-Williams FIRETEX intumescent paint, while the remainder was coated with a high-gloss finish.

All of the painting was done offsite at TSI’s paint shop so, once on site, the steel members, which are duplicated on many parts of the frame, had to be sorted and then erected in the correct sequence.

“Because of the nature of the structure, only certain parts need to be coated with intumescent fire protection,” adds Mr Betts. “This included the areas used by customers, such as the footbridge, staircase, floors and fire escape routes.”

The new steel-framed structure is supported by foundations cast into the top of existing reinforced concrete walls. The steel-frame is structurally-independent and gains its stability from cross bracings strategically positioned between the columns. The only location where the new steelwork connects into the adjacent swimming pool building is the link footbridge.

The footbridge is 7m-long × 4m-wide and is 3.2m-tall. The low-level walkway beams connect to an existing reinforced concrete beam, which is positioned under the floor within the main pool building, while the upper footbridge beams abut the adjoining structure, but do not connect to the swimming pool building.

“The steel-framed footbridge has been designed so it can be connected to the existing RC framed swimming pool without breaking through into the pool area,” adds Mr Hodges.

“Once complete, the actual break-through works will take place behind a sealed construction screen, which will be erected overnight, when the pool is not in use, which will then allow the break-through to continue safely behind it.”

Working alongside the steel erectors, SDC is also assembling the funnel and flume for the ride. Once the steelwork is in place and the cladding nearing completion, the final flume element will be installed to the tower and a weathertight seal made around the joint.

Center Parcs Whinfell Forest’s Tropical Cyclone is due to be operational by early 2023.