Projects and Features

Steel answers sustainability

In the first article of a two-part series, NSC publishes five frequently asked questions on sustainability for the steel construction sector.

The British Constructional Steelwork Association and Steel for Life have produced a series of 11 frequently asked questions (FAQs), with the support of the Steel Construction Institute (SCI), that aim to tackle several specifier questions focussed on steel, sustainability, and climate change. Here are the first five FAQs, and the remaining six will be featured in the next issue of NSC. Within this article readers can view the shortened answers to the FAQ’s, however longer and more detailed answers to each of the questions can be accessed on the BCSA website at: www.steelconstruction.org

1 Should I specify a high percentage of recycled material?

Recycling is good for the planet because it reduces waste and conserves (or substitutes) primary resources, furthermore recycling generally saves energy and reduces carbon emissions.

Specifying a high recycled content is a good driver for products where the aim is to encourage and establish a market for recycled materials that are otherwise limited, uneconomic or immature. This is not the case for steel however, which is already highly recycled (> 95% in the case of structural steel). Specifying steel with a high recycled content drives no positive climate impact at a global level, can have adverse consequences within the broader sustainability context and create market distortions.

It should be remembered that both major steel production routes use scrap. The primary or Blast Furnace-Basic Oxygen Furnace (BF-BOF) route up to 30% recycled content and the secondary Electric Arc Furnace (EAF) route 100%.

2 Why is European steel lower carbon than UK steel?

The lower average carbon footprint of European steel production is simply a function of the steel production split within Europe compared to that in the UK.

Steel is predominantly manufactured by either of two process routes, namely the primary or basic oxygen steel-making route (BF-BOF) and the secondary, electric arc furnace (EAF) route.

In Europe the production split (for all steel) is around 60:40 (BF-BOF:EAF). In the UK the production split is currently 80:20 (BF-BOF:EAF).

Typically, the EAF steel-making process has a carbon footprint around 20% that of BF-BOF steelmaking. Therefore, the European and UK average carbon footprint values for steel reflect these different production splits.

As a globally traded product, a UK average production mix for steel sections is meaningless. Instead, and where the steel supplier is unknown, for example at the early design stage, the BCSA recommends the following average UK consumption emissions factors for embodied carbon assessments of structural steelwork:

• For Modules [A1-A3], 1.74 tonne CO₂e per tonne of sections.

• For Module [D], −0.93 tonne CO₂e per tonne of sections.

3 Should I rationalise my design?

Rationalisation of steelwork design is common practice on most projects in the UK. The main drivers for this are constraints on design fees and time and efficiencies in procurement, fabrication and erection of the steelwork.

Reviews of steelwork designs have shown that some material efficiency savings are achievable by not rationalising designs but these studies also conclude that the main cause of over-specified steelwork is conservative engineering assumptions to retain a degree of flexibility or reserve in structural capacity.

4 How strong is S355 really?

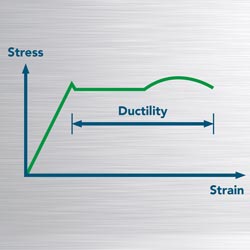

S355 steel is a European standard structural steel grade which has a minimum yield strength of ReH,min = 355 N/mm² for the smallest thickness range covered by the product standard. This is the nominal value of the yield stress, as opposed to the actual measured yield strength (which is usually higher). Steel structures designed to Eurocode 3 adopt nominal values of the steel properties as characteristic values in design calculations.

The new Annex E of prEN 1993-1-1:202X gives statistical data of properties for materials currently available on the European market, satisfying the relevant European product standards. For steel grade S355, the mean value Xm is 1.20ReH,min = 426 N/mm² with a coefficient of variation of 5%. The values currently adopted for partial factors γM are calibrated on this statistical data, considering a reliability index of 3.8 for a reference period of 50 years. This means that for design purposes, the nominal value cannot simply be substituted by, for example, a mean value without proper re-calibration of the partial factors in order to satisfy the reliability requirements from Eurocode 0.

5 How does the circular economy help today’s emissions?

There are many different facets to the circular economy including material efficiency, reuse and recycling. Steel has excellent circular economy credentials both as a material which is strong, durable, versatile and recyclable and, as a structural framing system, which is lightweight, flexible, adaptable and reusable.

While the focus of the circular economy in construction is on how to transition from a linear to a circular model, because of steel’s excellent recycling credentials steel is already circular with very little ‘leakage’ out of the system. Recovery rates for structural steel, for reuse and recycling, are over 95%. Globally, these high recovery and recycling rates translate into savings of around 950 mtCO₂ per year.