Projects and Features

New guide’s subdued response factor

Use of the latest design guide on hospital floor vibration has allowed a new Treatment Centre to be constructed in steel to a very tight programme. Jon Masters reports.

FACT FILE: Chichester Treatment Centre

Client: Royal West Sussex NHS Trust

Project Architect: Nightingale Associates

Engineer: Gyoury Self Partnership

Main Contractor: Henry Jones

Steelwork Contractor: F H Dale

Rapid construction of a new Treatment Centre for diagnosis and surgery at Chichester’s St Richard’s Hospital is on schedule for the first patients to be admitted in April 2005. That the building is being delivered on time owes much to new knowledge of vibration which confirms steel is a viable option for hospital structures.

In designing the innovative structure, consulting engineer Gyoury Self was substantially assisted by the Steel Construction Institute’s Dr Stephen Hicks, who provided a pre-publication draft of the new ‘Design guide on the vibration of floors in hospitals’. The guide, officially published in February 2004, encouraged the use of steel at Chichester and allowed the centre to effectively demonstrate that steel structures can meet stringent vibration criteria for hospitals both efficiently and affordably.

“The timing was perfect,” says Partner Chris Self of structural engineer Gyoury Self. “We were facing a problem just as Dr Hicks was finishing the new design guide that would ultimately provide the solution. Concrete construction was ruled out early on because the given programme of just 15 months demanded a quicker method of construction. A steel frame was the answer but meeting the existing design criteria meant quite large section sizes.”

Vibration is the dominant criterion in hospital de-sign. It is measured by a response factor that com-pares acceleration on a floor with the ‘base value’ defined in BS 6472, which defines the threshold of human perception to vibrations. Response factors for hospitals, set to cause minimal disturbance to patients and sensitive equipment, are limited to 1.4 in wards during the night and 1.0 for day- and night-time use in surgical theatres. This compares with a typical response limit for offices of 8.0.

Gyoury Self was initially working to the 1989 vibration design guide SCI Publication 076 for the design of the Chichester Treatment Centre. The firm had selected Corus’ Slimdek steel and concrete composite floor system for the two and three storey structure.

“Slimdek enables fast track construction and its relatively thin overall depth, of 335mm at Chichester, gives a lot of flexibility for services, which was essential as a performance specification had been set for the M&E works,” Self says.

“It also requires no additional fire engineering for one hour fire resistance and Slimdek’s in situ concrete slab provided sufficient mass to meet the desired vibration response. On an elemental basis, though, the guidance current at the time demanded heavy asymmetric steel beams to adequately stiffen the floor.”

“We had a scheme that worked but did not present cost effective use of the steel,” says Gyoury Self Senior Engineer David Simmonds. “That was until Corus put us in touch with Dr Hicks who gave us a draft copy of the new guide. This permitted us to reduce section size by about 40% overall and get rid of some intermediate beams altogether.”

The timing dates back to the spring of 2003 when the new design guide was in draft form after five years of work at the SCI dedicated to updating Publication 076. The research included dynamic testing of existing hospital floors with various structural steel arrangements. After determining the walking pace that produced the biggest floor response, controlled walking tests were performed to assess principal response factors.

Comparison with acceptance levels in the NHS performance standard Health Technical Memorandum 2045 followed and the steel composite floors were found to be well within minimum vibration requirements.

Writing the new design guide was the next step, working back from the response test results to refine analytical modelling of the floors’ dynamic properties. The resulting guide was published in February 2004. Crucially, it advises assessment of whole floors as an extension of the traditional practice of checking individual elements.

This was the critical difference made to the Chichester scheme. Simmonds says: “Dr Hicks modelled the whole floor in one hit using some quite sophisticated finite element software. This took the analysis one important stage further and backed up what the guide produced, which was an affordable design that met the vibration criteria.”

Confirmation of Gyoury Self’s new design was the green light for the Chichester Treatment Centre. Work started on site in October 2003 with erection of the steel frame beginning in January 2004. “Main contractor Henry Jones was casting floors by the February, which shows how quickly the steel went up,” says Simmonds. “The load-bearing masonry of an adjoining catering building was still only just coming out of the ground.”

Construction had to progress rapidly. Client the Royal West Sussex NHS Trust wanted the Treatment Centre to be accepting patients by April 2005 to improve service and waiting times.

The £12M Chichester Treatment Centre is one of around 15 currently being built as part of a national NHS building programme aimed at meeting Government waiting list targets. Treatment Centres are a vital part of the drive for more reliable treatment programmes because they will only provide routine diagnosis and surgery, without interruption from the demands of accident and emergency.

With several months of fit-out and equipment commissioning involved before the Chichester Treatment Centre could be declared open, a main construction programme of just 15 months was set. Henry Jones’ contract includes fit out of services and the contractor was able to start this towards the end of 2004, with more than a little help from the result of five years of steel vibration analysis.

Project Architect Nightingale Associates was given a brief of making the Chichester Treatment Centre a new entrance and focal point of St Richard’s Hospital. The response is a dramatic design. The two storey building is a U-shape, 45m wide by 50m deep in plan, wrapped around a 15m wide central atrium. This also leads to the core of the main hospital via a naturally lit corridor that bridges across other existing hospital buildings.

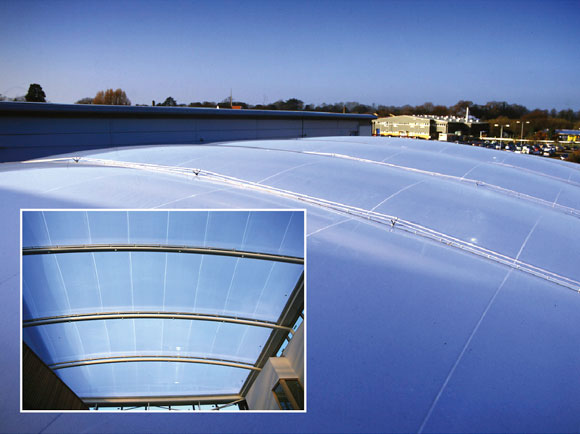

The atrium is an open space to the full height of the building, containing a new main reception area which is topped with a lightweight Texlon cushion roof supported by circular hollow sections. The roof has two skins of self cleaning Texlon, joined to create a pillow effect and inflated by a continuous supply of air to prevent condensation and create a naturally lit space protected from direct sunlight.

Another requirement was provision for future changes of building use. This has been accommodated by use of metal stud work for all internal walls with the exception of wet areas and lift shafts. Additional steel framing has been needed to support lead doors to X-ray rooms and bracing is provided by both diagonal cross-bracing and some portal frames to suit the architectural layout.

Vibration test

Results of real tests on real hospital floors have shown how well steel framed composite construction performs against the strict NHS vibration criteria. Limits set down in the Health Technical Memorandum 2045 are easily met by long-span composite beams of the type used so extensively in UK offices.

The longest span tested so far is 15m supporting a 175mm slab, which produced a response factor of 0.49 and a fundamental frequency of 7.6 Hz. This design provided enormous flexibility of the space below and a floor that comfortably met the required response factor of 1.0.

Steel frames are now the standard in the health sector and these are being chosen for their economy and efficiency. Now that it has become well known how easily standard steel floor designs meet vibration criteria, steel is being chosen for the speed and quality of build and the flexibility generated by long spanning solutions.