50 & 20 Years Ago

Luton Airport Hangar

Readers of ‘Building with Steel’ will recall that the back outside cover of No 1 featured a picture of a new hangar being built at Luton Airport. This building has been completed and in use for some while now and these notes and photographs describe the main features of the structure.

The hangar was commissioned in 1967 by the Airport and Transport Committee of the County Borough of Luton to be erected at Luton Airport where YRM had previously designed the Intermediate Terminal Building and the Airport Fire Station.

The building is provided for Britannia Airways who lease it from the local authority, and it was designed to accommodate the housing, servicing and operational requirements of the airline’s Boeing and Britannia fleet.

As this is the airline’s main base, the hangar has to cope with all aspects of the aircrafts’ maintenance up to and including complete engine overhaul together with work on the electrical and electronic systems. Two large store areas are also provided for the differing requirements of the Britannia and Boeing equipment. Substantial office components form part of the brief plus the usual amenities associated with this type of accommodation.

The site was established by the Authority as being adjacent to the existing Terminal Building, and is bounded on three sides by roads and on the air side by a new concrete apron ( not part of the hangar contract), connecting the building to the main Terminal apron.

As the major portion of the floor area is used to park aircraft, the special shapes, manoevrability and dimensions of the aircraft to be housed here becomes the prime factor in consideration of the configuration of the building, and this together with the office and workshop requirements produce the final building form.

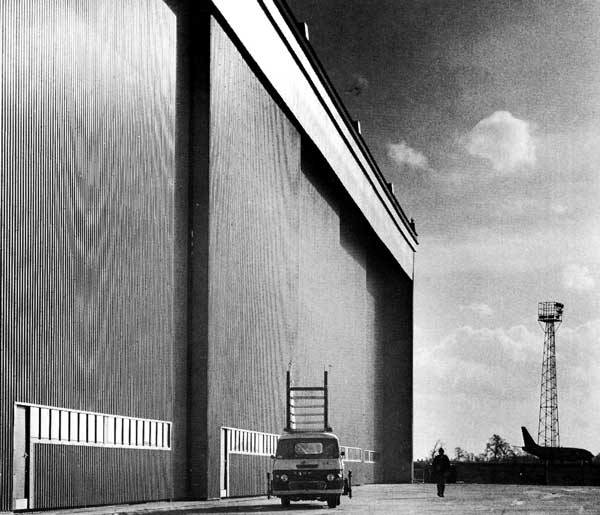

The main plan of the building forms a rectangle 378ft by 200ft, the long sides of which face the apron and the main road access.

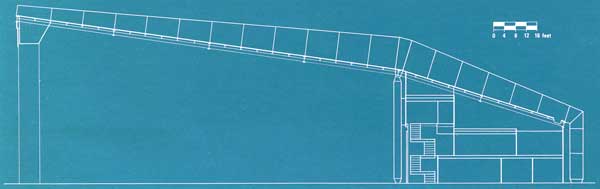

The structure to achieve this consists of 8 primary girders at 200ft long and this includes a cantilever of 140ft over the main hangar area rising from 40ft above ground at its root to 56ft above ground at its tip. The rear 60ft portions of the girders cover the workshop at ground level and the offices suspended from the main structure at 20ft above ground level. The centre 54ft bay also contains a mezzanine on which the toilet and canteen facilities are located. This structural system allows a completely column-free hangar and air side elevation.

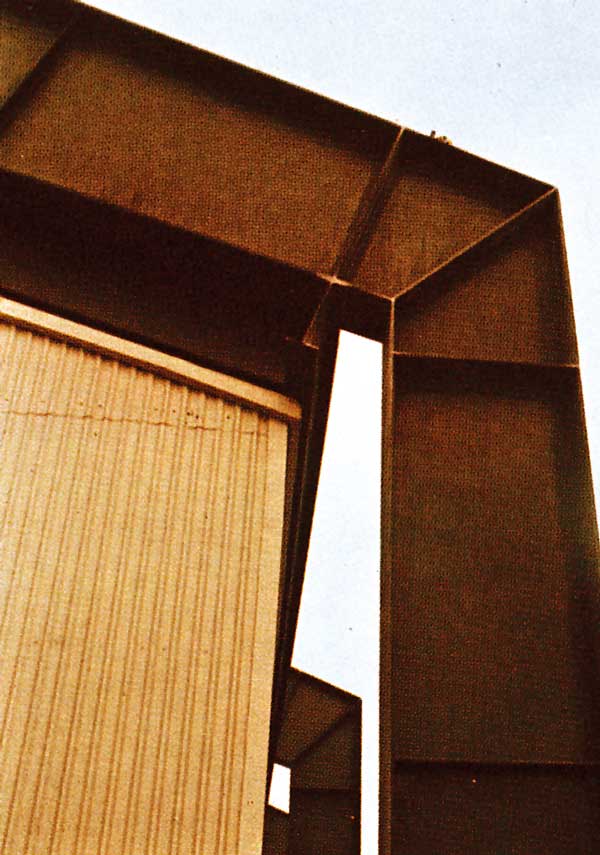

The structure below ground which includes a boiler house and electrical transforming system room is built in concrete, while that above ground is in structural steelwork. The primary girders are of welded construction, the plates varying in thickness from 1in to 3in and a secondary beam and purlin system is suspended from the main girder.

The main construction problem was the erection of these primary girders, and the solution devised by the design team in conjunction with the steelwork fabricators was to build the girders in sections on the ground, lift them to their intended location and weld the sections together in the air while they are supported on temporary trestles.

The seven hangar doors are of the sliding slab type 54ft sq. and also constructed in steelwork. They are electrically operated independently of each other, and in this way 70 per cent of the air side elevation can be opened at one time.

The cladding is a sandwich consisting of profile steel sheets externally, an insulation panel and a lighter profile steel sheet inner lining. This sandwich is used to clad all walls, the hangar doors, and is continued over the secondary beam and purlin system as the roofing.

In order to allow daylight into the hangar area, the roofing includes some sections of acrylic sheet profiled to the same section as the cladding.

The contract, value £621,000, was started in October 1968 and work was completed in August 1970.

Client

County Borough of Luton Borough Engineer

K. Seymour Esq Town Hall, Luton, Beds

Architects

Yorke Rosenberg Mardall Greystoke Place

Fetter Lane, London EC4

Quantity Surveyors

Steeds, 7 Clinton Terrace, Derby Road, Nottingham

Structural Consultants

Felix J. Samuely & Partners,

231 North Gower Street, London NW1

General Contractor

Tarmac Civil Engineering Ltd, Ettingshall,

Wolverhampton

Steel Work Fabricating and Erecting

Modern Engineering Bristol Ltd

Emery Works, Emery Road, Brislington

Bristol BS4 5PJ