Projects and Features

HS2 precast manufacturing facilities

FACT FILE

HS2 precast manufacturing facilities

Main client: HS2

Main contractor: ALIGN JV (Bouygues Travaux Publics, Sir Robert McAlpine, and VolkerFitzpatrick)

Steelwork contractor: Caunton Engineering

Steel tonnage: 2,400t

Structural steelwork is playing a pivotal role in the HS2 project, forming the all-important facilities that will enable the construction of the Chiltern tunnels and the Colne Valley Viaduct.

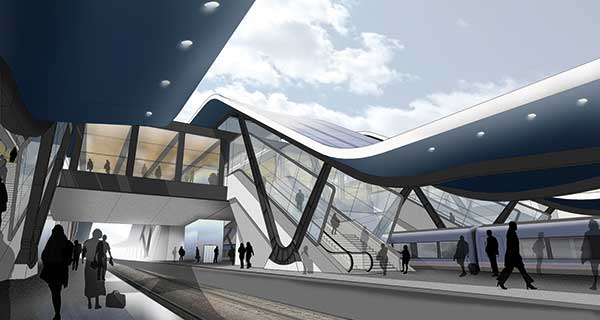

Europe’s largest infrastructure project, High Speed 2 (HS2) is a publicly-funded scheme which is kick-starting a major upgrade of the nation’s rail network.

Phase one of the project will link London and Birmingham on 140 miles of dedicated track. It will pass through more than 51km of tunnels and over 16km of viaducts, delivering quicker journeys on more trains with more seats. Phase one is scheduled to open between 2029 and 2033.

The initial phase of construction for this huge project includes the work currently being undertaken north west of London and just inside of the M25 motorway. Here a number of temporary steel-framed buildings are being erected, which will produce precast sections for the nearby 16km-long Chiltern tunnels and the 3.4km-long Colne Valley Viaduct.

Working on behalf of Align JV – a joint venture made up of three companies: Bouygues Travaux Publics, Sir Robert McAlpine, and VolkerFitzpatrick – steelwork contractor Caunton Engineering is responsible for designing, fabricating, supplying and erecting a total of 15 buildings.

The largest structures are a precast factory that will produce the concrete lining for the Chiltern tunnels and another facility, which will manufacture large precast sections, weighing between 100t and 140t, for the construction of the viaduct.

“Our large site for these new facilities is conveniently close to the tunnel’s south portal and the northern end of the viaduct, and we also have our own dedicated slip road off the M25,” explains Align Head of Communications Rob Hutchison. “This means we will be able to cast all the precast segments on site and avoid putting extra HGVs onto local roads, while the delivery of the required 2,400t of steelwork is also relatively straightforward.”

The steel-framed precast tunnel lining factory is a large U-shaped structure on plan, with two 125m-long outer parts, that feature 35m-wide clear spans, reaching a maximum height of 15m. Completing the U-shape is a 30m-long link building, that will be used as a storage area.

Structurally the factory is a portal-framed building, that supports two overhead cranes – one in each side of the U-shape. Consequently, it needed to have a sturdy design as the frame supports crane beams.

“Because of the crane movements in the completed building, we needed to keep deflections under control, so we designed the frame with larger columns than we’d ordinarily use and bigger base plates with more holding-down bolts, all of which provided the required stiffness,” explains Caunton Engineering Project Designer Ervin Sisak.

More than 100,000 precast segments, weighing up to 8t will be produced in the factory.

The facility will feed two giant tunnelling machines – named Florence and Cecilia – which are due to launch next year. The 170m-long, 2,200t machines will spend more than 3 years underground using the segments to line the tunnels and moving at a speed of approximately 15m a day.

A second precast plant will be used to produce sections for the nearby Colne Valley Viaduct. This structure is rectangular in shape, measuring 105m-long × 40m-wide × 28m-high. Internally, the building features a clear span of 35m, for the main production area, which is serviced by two overhead cranes.

As the steel frame of this structure also supports crane beams and will also be subject to deflections, due to the movements of the lifting equipment, the perimeter columns are attached to a second series of crane beam-supporting members, forming a stiff vertical truss around the entire structure.

As well as these two main factories, the remaining steel-framed buildings are also quite substantial and sizeable buildings.

For instance, there are three aggregate storage sheds, measuring 80m × 20m, 36m × 20m and 28m × 20m respectively. All three of these braced frames, consist of steel columns sat on top of 5m-high concrete bunker walls. Each has three clad sides, leaving one elevation open to allow trucks to enter and exit.

Other portal-framed structures serving the precast facility and its tunnelling works, are a TBM warehouse measuring 35m-long × 9.5m-wide × 8m-high; a general warehouse measuring 30m-long × 20m-wide × 7m-high, which also includes a 10m-wide lean-to structure; and one TBM workshop which also includes an overhead gantry crane.

Completing the total of 15 structures are three further warehouses and four large sheds for de-sanding operations, filter presses and other spoil treatment activities. The portal frames for the latter are all single-span 20m-wide structures with a combined length of over 400m.

Explaining the choice of steel for the temporary buildings, Laurent Auvinet, Align Package Manager, Precast says: “We looked at a couple of options, including the use of supported tarpaulins, but steel-framed buildings are the most effective, because once the work is complete, they can be disassembled and reused or sold.”

Once the precast plants are no longer required and have been disassembled, the whole site will be landscaped with material excavated from the tunnels and trees planted in order to blend it in with the surrounding countryside.

Summing up, Matthew Shimwell, Caunton Engineering Managing Director says: “We are thrilled to be working with the Align team in helping to deliver this key part of infrastructure work. The project is an excellent example of how early engagement with the supply chain brings real value to a project.

“This collaborative approach has helped to optimise the design of the buildings to more fully benefit from an informed DfMA (Design for Manufacture and Assembly) approach.”

The buildings for the tunnelling works will be operational by May 2021, while the viaduct precast facility will start up production in October 2021.