50 & 20 Years Ago

From here to infinity

This article was originally conceived as a fantasy on long spans. Although it was intended as light relief it was thought that it might encourage lateral thinking. While the original intention has not changed, the author, Eric Hindhaugh, submits that some of the thoughts that developed as the idea was pursued might be worthwhile considering for bridges of somewhat more orthodox construction.

There are two major obstacles to the design of very long bridges. The first lies in the properties of available materials to permit long uninterrupted spans. While the 3,000m or so suggested by Dr Flint is a very useful distance, there are times when a greater opening would be advantageous. Following from the first difficulty comes the second, which is that supports are necessary and for very long crossings they are apt to get in the way of shipping. While there seems to be no reason why ships can’t be brought through openings two miles wide when it is borne in mind that they ultimately have to negotiate much narrower channels at port approaches there does seem to be a fear that modern ships, tankers in particular, are so unmanoevrable that aiming through a bridge is beyond their abilities. So much for progress.

From these two points it follows that the ultimate in bridge design should have zero spans so as to eliminate the restrictions of the available materials and simultaneously infinite spans so as to eliminate the supports.

These apparently incompatible and irreconcilable requirements can be met however. While the following proposals might not be economic, might not even perhaps be practically possible (the author has no idea how much helium can be obtained), they are feasible and are interesting for what develops from them. As every reader must have gathered by now from the illustration the roadway is hung from balloons, or perhaps it would be more accurate to say from static airships. For lightly loaded structures, such as footbridges, there would be no difficulty in providing the necessary buoyancy but working on the principle of ‘in for one pence in for one pound’, I have examined the possibility of providing a multi-lane super highway capable of crossing (dare I mention it?) the English Channel.

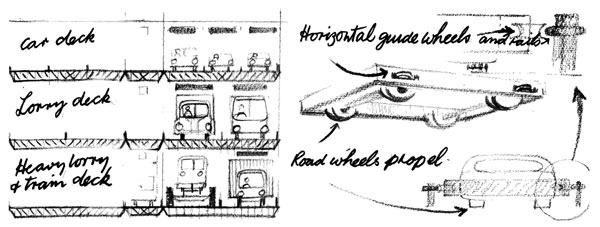

The basic proposition is to carry three decks of traffic. The upper includes three lanes in each direction for cars and light vehicles only – say up to about two tons each. The speeds in each lane would be controlled and would be 40, 55 and 70mph. The middle deck would be for medium weight commercial vehicles – say up to about 10 tons each – and would have two lanes in each direction with speeds controlled to 40 and 50mph. The lowest deck would be for heavy lorries and trains and the speeds would be 30 and 50mph.

It would be difficult, of course, to drive a long distance in a relatively narrow lane and the consequences of a driver falling asleep are not to be contemplated. For this reason it is proposed that all vehicles are totally controlled in direction and speed by the bridge itself. The modus operandi is quite simple. On arrival at the toll gates each vehicle receives a framework of standard size for its deck so that for cars, for instance, it might be about 25ft long and 10ft wide. The inside of the frame would be softpadded to prevent damage to the car. The frame would have its own running gear for the road deck and horizontally for the guide rails. In effect then the driver has only to maintain a light hold on the steering wheel, sufficient to keep the wheels approximately straight, and a foot on the throttle to maintain his speed. The guide rails would be arranged in sections about 50ft long such that the forward end can be moved inwards to narrow the gap while the rearward end is simply hinged. The normal and failed positions of the guides are open, i.e. narrowing the track. As a car travels through, the tracks in front open to give a clear run. However, they cannot open at speeds different from the control speed for the lane unless overridden manually by the bridge staff in the event of an emergency. Should a driver attempt to exceed his set speed he would find himself being braked by the guide rails. Similarly if his speed falls below that set, he will find himself being braked. Only at the correct speed would life be comfortable. The guide rails would also be programmed to prevent vehicles getting too close to each other and the bridge would be perfectly safe to use in thick fog. In addition to the automatic braking the bridge would have sets of traffic lights shining only red or green. This would enable the driver to control his speed by keeping a set number of lights ahead on the correct colour. In addition, should there be a break-down in his lane he can apply his own brakes as well as relying on the guide rails and thus avoid pressure on the front of the car. If a car breaks down all cars behind would automatically be braked in safety. Meanwhile the rescue and break-down crew would soon be in position and would override the guides, enabling the obstruction to be bypassed and also removed rapidly to return the lanes to normal running. The middle deck would operate in much the same way.

The lowest deck would be similar but it is not thought that exceptionally heavy or bulky loads could be carried except by special arrangement, probably at night and by using both lanes.

Whereas the upper two lanes are for road traffic only, the lowest is for both road vehicles and for trains. In complete reversal to proposals for a Channel Tunnel, I suggest that for a bridge the trains are carried by road vehicles. The reasons are several and are attractive. Loading a train with road vehicles must take considerable time as each has to be driven on, parked, braked, checked and locked. Loading a road transporter with a train is only one movement and would take much less time. No special tracks are required and normal road vehicles can run between the trains, thus there is no ‘dead’ highway.

Because the train is now running on pneumatic tyres it can be braked as quickly as a lorry – in fact quicker, because the guide rails would help out also. It would run silently compared with the noise of a normal train running on an all-steel bridge. Since braking is superior trains could be run at much higher intensities. The impact loads on the structure would be much less than with normal trains and this would help to reduce the bridge weight.

There is no shoulder on this bridge, as with most bridges. Nonetheless, break-downs will occur and must be dealt with quickly to prevent congestion. For this purpose there is a middle lane on each deck reserved exclusively for rescue operations. Running on each deck would be a number of combined vehicles including fire-fighting equipment, vehicle servicing of the ‘get-you-home’ type, cranes to remove vehicles unable to run, first-aid and ambulance and perhaps an emergency operating theatre, although since accidents are virtually impossible the last might not be required. These vehicles would be drivable from either end and should be able to reach say 100mph. In this way they could service any part of the bridge within about three minutes of being called.

Although the above operating systems were evolved for the ‘infinite-span’ bridge, most, if not all, would be equally applicable to any large capacity bridge of great length and might warrant further development.

Passing now to the structure it can be seen that it is suspended from the ‘air ship’. Since the hangers are in pure tension their total weight is constant and independent of the number employed. This is distinct from struts where the weight will vary depending on the chosen proportions. We could therefore have one set of hangers for each cross-beam and, in effect, eliminate longitudinal beams entirely, except for alongside the central track where access to the lanes will be necessary. The cross-beams should be of lightweight construction and open lattices are suggested but other forms might be preferable. It might be worth while employ-ing a type of space frame for better load distribution.

Unlike suspension bridges, the deck system would not have to provide longitudinal stiffness, consequently no girders are included along the length. The cross girders are continuous and have high tensile wire diagonals, crossed in the central zones, so that moments are catered for in either direction. Great use is made of high tensile steel wire in the interests of weight saving.

The running surface also needs to be as light as possible. Steel plates with non-skid surfaces might be suitable or perhaps thin layers of granite-like material could provide a useful working life. In fact wear should not be very excessive – after all there should be little acceleration or braking, no cornering, no impact, no frost or rain and no sun – few roads have had it that good.

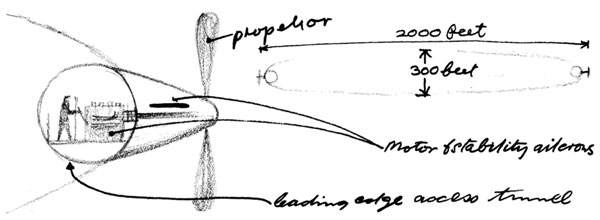

I can no longer dodge the issue of how to hold it up. Frankly, I don’t know whether this would work in every respect but it seems to me that the following ideas are feasible.

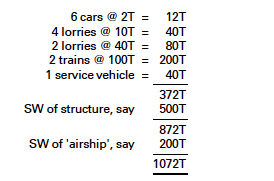

The load per lineal foot of the bridge under the most adverse conditions is probably almost 11 tons. This is made up as follows: for every 100ft length there could be 3 cars, 2 medium lorries, 1 heavy lorry and 1 train (excluding locomotive) in each direction, plus central lane service vehicles. Allowing 2T per car we get:

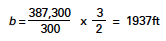

So for 100ft length, weight is 1,072 tons and weight in lbs for 1 ft length

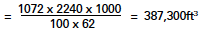

The lifting power of helium allowing for a reasonable level of efficiency is 62lb per 1,000ft³; so cu.ft required per lin.ft

Assuming that the volume of the ‘airship’ is given by

then for a height of 300ft, the breadth is given by

The problem now is how to keep the structure stable and in position. The height would be monitored by a number of photo-electric cells mounted on the upper surface and related to fixed installations on the cliff tops or on towers at each end. As soon as any deviation from normal is registered one of two methods could be employed to maintain height, depending on the condition. The first would be by adjusting the ratio of helium to air in the gas tanks. Since the balloon would be divided into compartments selective adjustment would be possible. The second method would be to alter the shape of the structure so as to create more or less lift from the passing airstream. There would be very few days in which there would be no wind blowing so this source of adjustment would usually be available. A combination of the two methods should cater for all needs with aerodynamic control for sensitive instantaneous correction and gas control for long-term adjustment, necessary perhaps for seasonal or night/day variations. These two methods should cater for height.

Lateral drift would be caused by wind and over the distance it could be blowing in several directions. However, if airships can fly through the wind and achieve actual movement relative to the ground, then equally with a little less power they could remain exactly in one position. The proposition is that motors (I’m not sure which type – diesel, electric, gas turbine) would be mounted along the edges of the structure and would drive airscrews. Immediate adjustment of force would be effected by blade pitch variation with longer term control by changing the motor speed. Pitch control should cater for local gust effects and motor speed with basic wind velocity. There would be a degree of stiffness in the structure and considerable inertia, so no potential movement is likely to be rapid and control mechanisms should be able to apply corrections quite easily.

The third type of movement would be pitching of the gas container by gusts hitting one edge. Again it should be possible to effect control aerodynamically by moving the edge blades. Taking into account the inertia of the structure and consequently the slowness of any movement, it seems quite feasible to expect modern control systems to maintain the position and stability of the structure within very close limits. Assuming this to be so, the bridge would have the unusual properties of being the longest span in the world and yet being free from deflection both vertically and horizontally!

The roadways would never be wet as the gas container would provide a very adequate roof. Snow would not probably get near the roads but perhaps this might be possible in a blizzard. The amount would be little, however, and could probably be deflected from the roads by quite simple means. Snow on the gas container would be most unwelcome and ice even more so. However, the skin could contain heating elements to ensure that ice would not form. Perhaps it would be possible to have a double-layer skin with hot air circulating in the cavity. This type of bridge has no span limits and could circle the earth. We could have motorways linking all countries and all continents. Strictly speaking, of course, the title of the article isn’t correct, but perhaps I can be allowed a little licence as a span of 24,000 miles is not bad going.

At the present time, crossings are made by dynamic means with boats, hovercraft and aircraft, or statically by tunnels or fixed bridges. In the past these two principles were blended in pontoon bridges and the proposals in this article could be said to be a modern version of the same idea. It was good enough to get Xerxes across the Hellespont – could it be also good enough to get John Bull across the Channel? If it should be thought that the control systems would be unable to cope, I can only suggest that since it is possible to pilot automatically a fully-loaded jumbo jet across the Atlantic and land it at up to 200mph on a relatively narrow track after controlling its position three-dimensionally for 3,000 miles, it should be possible to maintain a relatively fixed structure in one position without too much trouble. Finally – how would it look? Well, this is a subjective area and it would be silly to claim that everyone should like it. But, vast though it is, the proportions are slim and I can’t help feeling that this flattened silver sausage, spanning freely across the Channel and catching the myriad lights and colours from the sky, would be one of the most exciting structures known to man.

From Building with Steel, May 1973