Projects and Features

Extension cleared for take-off

FACT FILE

London Southend Airport, haul baggage shed

Main client: London Southend Airport part of Stobart Group

Architect: CPMS

Main contractor: XYZ Rail & Civils

Structural engineer: Waldeck Consulting

Steelwork contractor: Border Steelwork Structures

Steel tonnage: 50t

London Southend Airport is forging ahead with its expansion plans that include an extension to the terminal building’s baggage area.

Prior to the aviation downturn caused by the ongoing COVID-19 pandemic, London Southend Airport was reported to be the UK’s fastest growing airport and in 2017 there was a 29% increase in passenger numbers taking the figure to more than one million.

It is said that the Essex airport has capacity to comfortably handle five million passengers in the near future and take up the slack over the next decade before a prospective third runway opens at Heathrow.

As part of a multi-million-pound ongoing masterplan, the airport owner Stobart Group has lengthened the runway to enable larger aircraft to use London Southend Airport, as well as carrying a number of alterations and expansions to its main terminal building.

The steel-framed terminal building was constructed nine years ago, as the Airport geared itself up as a convenient gateway for the London 2012 Olympic Games (see NSC March 2011).

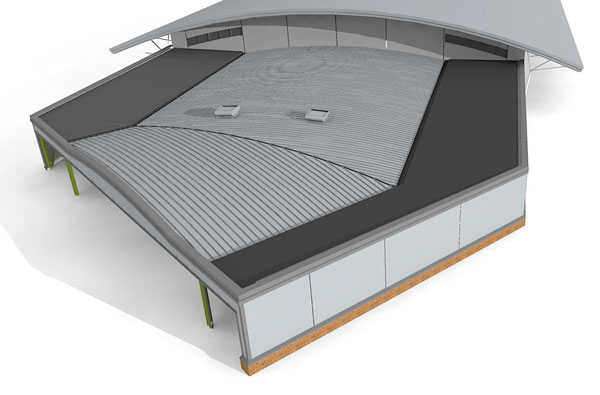

One of the important elements of the Airport’s plans for its terminal building is an extension to its haul baggage shed (HBS).

“The extension is required in order to comply with Department for Transport regulations to screen luggage using Standard 3,” explains XYZ Rail & Civils Senior Project Manager Roy Hill.

“As the Airport grows it needs to have the latest Standard 3 security X-ray equipment in the HBS, so we are building an extension that wraps around the existing area on three sides to house these new machines as well as an extension to the conveyor system.”

The existing terminal building is a steel portal frame structure, and so is the extension, which consists of moment connection portal frames constructed from 254 UCs and 406 UB main rafters.

The extension structure abuts the existing terminal building, but there is no connection between the two steel frames, which are both structurally independent.

“Once the cladding has been installed the two will blend and look like one complete building,” adds Mr Hill.

Before the steelwork erection for the extension could begin, a groundworks programme had to be completed. The work included the installation of approximately 50 piles, up to 15m in depth, and the casting of ground beams and the main concrete slab.

The subsequent steelwork programme was divided into two phases, with the first, which accounted for around four fifths of the overall total, erected prior to the first COVID-19 lockdown in March 2020. The project’s steelwork contractor, Border Steelwork Structures (BSS), also installed the extension’s cladding, 80% of which was also complete before the lockdown.

With easing of restrictions, the phase one cladding was completed in August.

The phasing of the steelwork and cladding installation was necessary as the Airport had to maintain its baggage capacity throughout the works. A temporary baggage carousel, installed to boost capacity before the extension comes online, had to be removed prior to the phase two works beginning.

The HBS wrap-around extension measures approximately 47m-long × 39m-wide with a maximum height of 5.2m. Although it is independent of the main structure, it does connect to the existing baggage handling structure’s canopy.

The main portal span is 22m-long, while column bay spacings vary due to the shape of the structure, but they are mainly 6.85m.

One side of the frame has a large opening for baggage vehicles. This part of the extension will have exposed columns, which need to be protected against vehicular impact load.

Explaining the stability system for the standalone extension, BSS Technical Manager Ian Elliott says: “The lateral load induced by the wind will be transferred to the columns via the external cladding and then down to the piled foundations situated in the bearing strata.

“Lateral stability is provided in-plane by the moment resisting connections of the portal frame structure. Out of plane lateral stability is provided by vertical bracing located on two sides of the extension structure.”

The installation of the steelwork and the cladding was done using the site’s tower crane and one mobile crane.

Because of the proximity of the functioning airport, the cranes had to be positioned so they did not over-slew any areas outside of the construction site, while a maximum height of any lifting operations was also enforced.

“We are continually liaising with the Airport authorities, to iron out any potential problems,” says Mr Hill. “We have a security fence around our site which effectively seals us off from the airfield and the ‘live’ environment, keeping all of our operations landside.”

Phase two of the steelwork and cladding was completed during December, and construction work on the extension is due to complete in March.

A fit-out programme is then due to begin in June, with the new and enlarged HBS coming into full operation later this summer (2021).