Projects and Features

Campus construction boosts local economy

Built on a prominent hillside, the Alloa campus will overlook the town and the surrounding countryside

A new campus at Alloa represents the initial phase of Forth Valley College’s ambitious plans to upgrade its three main centres. Martin Cooper reports.

FACT FILE: Forth Valley College, Alloa campus

Architect: Reiach and Hall Architects

Main contractor: Miller Construction

Structural engineer: Halcrow Yolles

Steelwork contractor: Hescott Engineeering

Steel tonnage: 350t

Project Value:£21M

Forth Valley College is the fifth largest college in Scotland and currently undergoing a large scale modernisation programme consisting of the construction of two new campuses at Alloa and Stirling.

At both locations, the work involves the building of new premises to replace ageing town centre campuses. The new structures will provide students and local business communities with state-of-the-art facilities, while also giving a boost to the region’s economy.

The first of the two projects to get underway was Alloa and here the job is helping students gain vital work experience as well as creating more than 130 jobs in a sector under pressure in the current economic climate.

Keith Brown, Minister Scottish Parliament (MSP) for Skills and Lifelong Learning said: “We must continue to stimulate the economy when and where we can in order to support a strong recovery.”

The new Alloa campus is a 6,000m² structure being built on the site of a former council office. Once complete this summer the college will relocate from its existing Alloa premises into its new modern and eye-catching campus.

The most noticeable feature of the site is its topography and this has presented main contractor Miller Construction with its biggest challenge. In order for the new structure to overlook the adjacent main road and town centre and maximise the site’s footprint, the structure has been built into a slope that dominates the site.

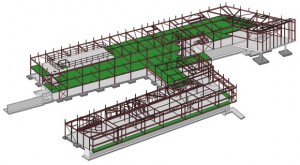

Featuring a workshop block at the front, the building rises up the slope via concrete retaining walls. A two-storey link block straddles the walls and allows access into the main teaching block which sits at the top of the slope and overlooks the main road as well as the workshop area.

“We initially had to remove an existing retaining wall and then construct new retaining walls for the college’s stepped levels,” explains John Downey, Miller Construction Senior Project Manager for both the Alloa and Stirling sites.

Building new retaining walls, earthmoving and then backfilling took approximately 12 weeks to complete. The lower level of the project was then vibro compacted prior to pad foundations being installed, while on the upper level – which consists mostly of stiff clay – the pad foundations were able to be immediately installed.

Locally based Hescott Engineering was then able to begin its 10 week steel erection programme for the main frame.

Speed of construction as well as cost drove the decision to go with a steel frame. On this project time is of the essence as the campus is due to be open in the autumn.

“Steel was selected as the primary construction material for two main reasons. The cost was a key factor, however with a challenging programme it was clear that the flexibility to incorporate design changes as the scheme developed would be essential,” explains Gary Farquhar, Halcrow Yolles Senior Engineer. “With the steel procurement process changes can be incorporated right up to fabrication.”

The steelwork configuration for the main teaching block is based around an irregular grid pattern, as the block consists of various sized rooms. The longest spans are however in the 10m region supporting hollow core floors spanning up to 9m. Stability for the frame is provided by conventional cross bracing placed in corridor partitions and external walls.

Because of the sloping site, the teaching block has a partial basement, making the structure a three-storey building in places. This basement area can only be accessed from the rear and will be used for storage. The main entrance to the block is located on the first floor along with some teaching rooms, while the uppermost second floor is completely taken up with classrooms.

The floors of the teaching block have all been constructed with conventional rolled sections in conjunction with Deltabeams.

Deltabeams are one of a number of steel shallow floor solutions.

“For the teaching block a relatively clean soffit was considered attractive by the design team. Minimising storey heights also provided a beneficial cost balance by reducing the height of the feature and very high specification masonry cladding,” says Mr Farquhar.

In order to speed up the erection of the Deltabeams, Hescott installed the beams in regular 9m long continuous lengths, erecting the teaching block’s columns on top of the beams and in storey high sections.

The western end of the teaching block culminates in a feature library which overlooks the town and has an 8m-high glazed elevation. This block is supported on a large flat slab with only two minimal RC columns supporting it. The designers also had to be mindful of horizontal deflection because of the full height curtain walling.

For the single-storey workshop a more open plan arrangement was required and a rectangular grid of up to 12m x 10m was used throughout. A more traditional beam and column steelwork frame was erected for this part of the project.

One of the main design challenges centres around the workshop which overlooks and cantilevers out over the adjacent main road. Although the cantilevers are only 2.5m, each is heavily loaded, supporting up to 12m lengths of brickwork façade and long span concrete floors.

“While the tall cantilever façade was heavy, the workshop roofs were relatively light, which gave us an interesting dilemma,” adds Mr Farquhar.

To overcome this, Halcrow Yolles designed long span compound sections. The projecting cantilevers continued as ground level concrete encased compound sections running 10m back to the internal column base. The composite action helped limit deflections in the cantilever tip, while the 10m lever ensured the self weight of the lightweight roof and related pad foundations was sufficient to resist the uplift force generated by the cantilever.

“One of those hidden details which are rarely appreciated by the end users, but give the structural engineers enormous satisfaction”, said Mr Farquhar.

The new campus development will have space for up to 2,900 students per academic year, across all modes of attendance, and will include high tech-specification teaching rooms, workshops, gym and cafeteria. The campus will offer provision in subject areas such as construction, engineering, motor vehicle maintenance, science, business, computing, childcare and education, creative industries, hairdressing and beauty therapy.

Forth Valley College’s Alloa campus is scheduled for completion during the summer of 2011.