50 & 20 Years Ago

Non-Industrial buildings

A large number of schools today are built using some form of catalogued building. One of these is SCOLA, the commercial member of which is Sanders & Forster Ltd. Mr R. S. Brocksom, a Director of that company, describes the use of systems in schools, hospitals and commercial buildings with special reference to the SCOLA method.

The educational field is where system building has achieved its greatest degree of success by any standard of measurement. Founded on the work of Hertfordshire in the fifties and then the formation of the large consortia of local authorities, CLASP (1957), SCOLA (1961) followed by SEAC, CMB, ONWARD, CLAW, MACE, etc, the position has now been reached where about two thirds of all schools started in 1971 will be system-built schools. The SCOLA system will, in fact, be starting its 1,000th project in 1971. Most of the above systems are fully steel-framed, whilst the remainder have steel roof structures

All of these systems are client sponsored, designed by architects for the use of architects, and have been constantly developed through the years since their inception, so that they are, in the main, quite sophisticated, with a wide range of options using both ‘system components’ and building materials and products available in the open market. They are therefore a mixture of the ‘closed’ and the ‘open’ systems, depending on architectural choice, a situation that is helped by the provision of a basic steel frame following the accepted rules of dimensional coordination and acting as an accurate matrix for all the other building elements.

A ‘closed’ system, using only the range of components laid down by the system designer, may well be in the right cost bracket, but leaves little architectural scope to the job architect, whilst the ‘open’ or ‘half open’ systems allow him a much higher degree of architectural freedom, still within the allowable costs.

The economics of the client sponsored systems are based on competitive tendering at two levels. At the level of building components, the consortia seek tenders based either on performance specifications or enquiries for specific products. This results in bulk purchasing arrangements at keen prices for a large proportion of each building project. Then, at the second level, each separate building is usually offered in the normal way to the competitive tendering of builders, either singly or in serial.

The local authorities who are members or associate members of consortia (e.g. 54 out of 59 English and Welsh counties) build in their systems for a variety of reasons:

- (a) Within the limits of expenditure laid down for them, and respecting the principles of competitive tendering, their systems give them better value for money than ‘one-off’ construction.

- (b) Their systems give much more dimensional flexibility and many more architectural options than any ‘closed’ or ‘proprietary’ system at the same price level.

- (c) The job architect, relieved from the chore of detailing every element and assembly in his project, has much more time available to spend on the design and planning of his building- his total time commitment being much reduced.

- (d) The preparation of bills of quantities and other documents and drawings needed for competitive tendering all become less time consuming, whilst the provision of building information to the successful contractor is simply a matter of extracting and issuing the appropriate sheets from the system manual – allied to the layout and elevation drawings prepared by the architect for the particular project.

- (e) The saving in time in the constructional process itself varies appreciably with the circumstances of each job, but many school building authorities have cut their old traditional building times by one-third.

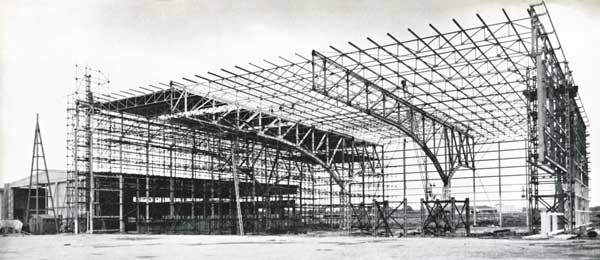

The design, detailing and fabrication by batch production of the steelwork components for system building needs a specialized knowledge and experience that only a few members of the constructional steelwork industry have accumulated.

Sanders & Forster Ltd, who are now providing the steelwork for four schools per week in the SCOLA system, have to date designed the structural components for six consortium systems for educational buildings, plus one system for hospitals and one system for supermarkets and warehouses, and a comprehensive range of standard buildings for industrial and commercial use.

These standard industrialized buildings, computer designed to plastic theory in a very wide range of spans and building lengths, have so far been portal frames of varying types, complete with several varieties of wall and roof coverings, both for the home market and already exported to over sixty countries overseas. This type of pioneer work, together with the development and introduction of new types of plant, new works procedures and processes, has resulted in Sanders & Forster Ltd being, so far, the only firm of constructional engineers to be awarded the Queen’s Award to Industry for technological innovation.

Additionally, Sanders & Forster Ltd is now launching the Multiplan range of flat-roofed buildings for industrial and commercial use, which have alternatively steel or concrete columns as the architect may require.

As the commercial member of the Second Consortium of Local Authorities, Sanders & Forster Ltd are authorized to offer complete SCOLA buildings outside of the SCOLA membership and to arrange for the export or the licensing of the SCOLA system overseas.

In the field of hospital building, a number of structural systems are available to Hospital Boards under the I H B scheme sponsored by the then Ministry of Health in 1968, and based upon the official performance specification prepared by the Ministry and their advisers.

Bearing in mind the traditionally lengthy periods spent in planning, design and construction of almost all hospital buildings, it is remarkable that these I H B systems have, up to now, received so little support from the Hospital Boards.

In considering the very large part played by steel as a material in system building, both in structural and non-structural components, one can recognize that the prime advantages of its high strength/weight and strength/cost ratios, together with its potential for consistently accurate fabrication, are factors that meet the basic need of all ‘open’ or ‘closed’ building systems. That is, the accurate assembly of diverse components from many sources and the elimination of the traditional building skill of getting over dimensional inaccuracies in site work.

The basic steel frame of a system, assembled from jig-tailored components, can give on site an extremely accurate skeleton that controls and simplifies the proper assembly of all the other building elements – in other words, it is an essential part of any system.