Projects and Features

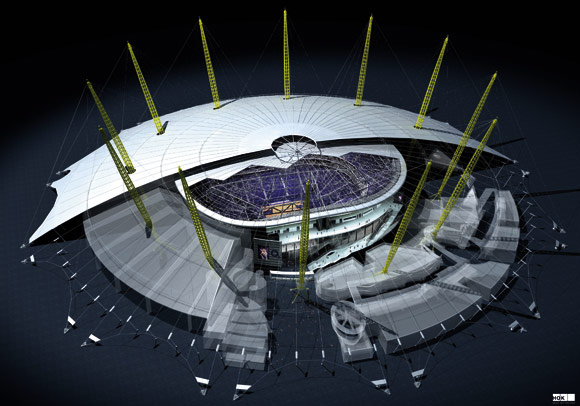

A roof within a roof

Formerly known as the Millennium Dome, London’s giant big top is set to be reborn as a US-style entertainment centre with a 23,000 seat arena, bars, restaurants and exhibition and theatre spaces. Martin Cooper reports.

FACT FILE: The O2 , London (formerly the Millennium Dome)

Main client: AEG Europe

Architect: HOK Sport

Structural engineer: Buro Happold

Main contractor: Sir Robert McAlpine

Steelwork contractor: Watson Steel Structures

The structure previously known as the Millennium Dome is finding a new lease of life as The O2 , a major entertainment and leisure complex taking shape at Greenwich, London.

This will be a new American-style entertainment complex, born from a collaboration between US based developer Anschutz Entertainment Group (AEG) and corporate sponsors O2. The Dome as we knew it will be no more, and the entire site has now officially been dubbed The O2.

Central to the whole redevelopment of the dome is the 23,000 seat enclosed arena which is being created inside the original dome structure, set to open in early 2007 to host both sporting and music events.

Constructing an arena inside an existing structure is certainly unusual and the design threw up a number of unique challenges. Not least being the 2,500t steel roof (which weighs 4,000t when fully clad) for the arena, which has only 4m clearance below the dome’s fabric roof.

Using tower cranes within the dome to erect the roof was out of the question, says Ken Jones, Associate Director at structural engineers Buro Happold. “There just isn’t the room.”

So the roof was initially assembled on trestles on the dome’s floor and then jacked into position. Putting a roof on the arena also means it is ‘future proofed’ and could stand-alone if the enclosing dome structure was ever dismantled.

Mr Jones says the design and construction of the arena’s roof has driven the early stages of the project.

Watson Steel fabricated the roof’s steelwork at its Bolton facility and transported sections to the site in pieces no larger than 3.5m wide or 22m long.

Paul Hulme, Watson’s Project Manager, says approximately 600t of steelwork that has been used for the arena roof was made up of two primary trusses, each of tubular construction and 130m long, which were brought to site in sections and welded together on the ground.

Spanning the void between the primary trusses are 16 central trusses with spans ranging from 30m to 60m. Each of these members has a depth of more than 5m. Radiating from the primary trusses are four secondary trusses which are 5m deep and nearly 40m long.

And finally, stretching around the entire roof there is a perimeter truss, again made up of tubular sections.

As Mr Jones explains, this is no ordinary roof, as the spherically-shaped structure is 11m deep at its apex and very deep trusses were required because of its 150m maximum span.

This roof space is needed for a vast array of equipment. Up to 50t of equipment can be hung from the roof such as lighting and sound equipment and a huge scoreboard – dubbed the Gondola – that will be lowered for sporting events. There are also large ducts for the environmental control of the arena and acoustic cladding.

Eight concrete bearing cores, housing everything from stairs, lifts, air ventilation shafts and risers, were, however, the first part of the arena to be constructed. The steel roof was then constructed around these cores at ground level.

The two primary trusses were then laid out and all other trusses were bolted around these, including the secondary and perimeter trusses.

Four opposite cores were designed and constructed with inlaid grooves to accept the primary trusses. These grooves, as Mr Jones explains, were then used to facilitate the final jacking process.

“We also designed four quadrapods to sit on each of these cores. These supported the main trusses during the jacking process and were then twisted and lowered down once the trusses were resting on the cores.”

During the early part of March, the entire roof was jacked into an intermediate position approximately 11m above its previously supporting trestles.

Then, at the end of March, the final process of raising the arena’s roof took place over two night shifts. Computer controlled strand jacks installed in the roof inched the structure up cables, attached to the tops of the eight cores.

“Once the roof was in position we then in-filled the missing elements of cladding over the tops of the cores,” Mr Jones explains. “And once the roof was raised, a clear space was opened up and work could then begin on the rest of the arena.”

Steel construction will also play a pivotal role in the erection of other elements within the complex. The majority of the arena’s frame will be steel, while the mezzanine floor has also been designed as a steel framed structure. Watson Steel is supplying approximately 1,200t of steel for this part of the project, including cigar-shaped rakers with a tapered depth of 550mm to 900mm and back to 550mm. These will support the upper tier seating, while a variety of UBs will be used on the lower tier.

Another large steel framed structure, situated adjacent to arena, sits on top of a large and already complete service yard and will require Watson Steel to supply 2,200t of steelwork. This building will be constructed with 14 x 3m deep primary trusses formed into an arched configuration.

“Once the frame of the casino has been built the 50m span steel roof will be bolted together while resting on the frame. It will then be lifted into position by two cranes and bolted to another section of roof attached to the arena building,” Mr Jones says.

What’s in O2

The 23,000 seat arena is the overall centrepiece of the redevelopment. However, there is vast space to fill inside the dome and other developments include a large casino, depending on Government legislation. Main contractor, Sir Robert McAlpine also has a contract to build a 32,500m² entertainment zone, known as the waterfront development. This will include a 2,200 capacity music club, 6,000 seat exhibition centre housed in a glass-framed bubble and an 11-screen cinema. The area will have an array of restaurants, bars and other leisure facilities.