Weekly News

Voortman launches new punching and shearing machine

The new Voortman V505-160T punching and shearing machine has been designed specifically for the steel fabrication sector and is said to offer high-speed processing and less wastage.

The new Voortman V505-160T punching and shearing machine has been designed specifically for the steel fabrication sector and is said to offer high-speed processing and less wastage.

With the all-new Voortman V505-160T, the time required to complete a full production cycle is shortened by up to 25% in comparison to equivalent punching and shearing machines according to Voortman.

This significant performance benefit is calculated from the complete process, starting from infeed of the first angle profile to a fully processed end product and readiness to feed in the next profile. Voortman says the results were confirmed by extensive tests and detailed customer feedback.

As well as fast punching and shearing, high-speed processing is accomplished by an automatic infeed, which comes as standard equipment on the Voortman V505-160T. The servo driven gripper truck is equipped with a material sensor for full-speed approach and it runs at a maximum speed of 110m/min, making it one of the fastest gripper trucks on the market.

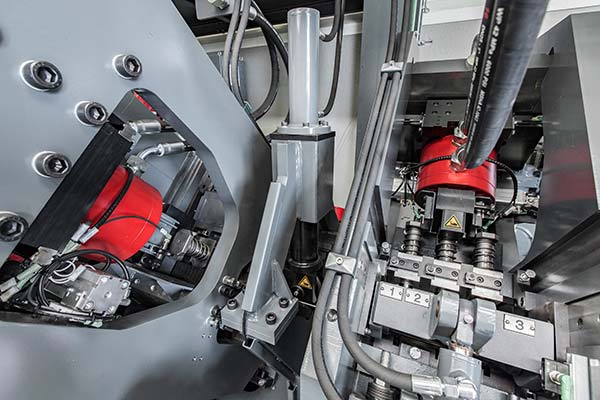

The two rigid punching frames, each holding three punching tools, are mounted on a sliding frame with a hinge and a spring load to prevent vibrations in the machine while punching. The positioning of the punch frames on two linear guidance rails is done with a spindle and a servo drive, reaching a high maximum speed of 15m/min.

On each punching frame, an 80t hydraulic cylinder is mounted which punches angles up to a maximum thickness of 19mm. The punching cylinder is mounted on two linear guidance rails and driven with two pneumatic cylinders for fast tool selection. Each punch block weighs 7kg, enabling easy tool changing for the machine operator.

The machine’s shear is equipped with a 245t cylinder for cutting and with a material holder just in front of the shear to keep the material steady during the cutting.

The shearing blade itself is optimized on all four corners to cut every angle in the range from 35mm to 160mm with the right radius.