Technical

The case for steel – Sustainable steel aims at Olympic gold

Our Case for Steel series continues with an overview of the strong sustainability benefits that flow from selecting steel. Demountability is one of the key benefits, which featured in the winning bid that secured the 2012 Olympic games for London.

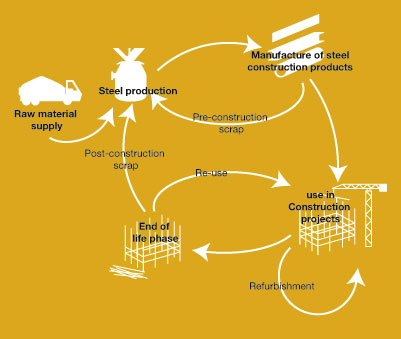

The sustainability case for steel is the strongest of any construction material. Unlike other building materials steel is multicyclable, meaning that it is available to be recycled and used in building projects as the structural element again and again.

Regardless of the number of times it is recycled, steel’s performance as a structural material is not impaired. The basic raw material is the most plentiful element on our planet – and given that steel can be recycled indefinitely little of it will ever be truly wasted.

Virtually no steel ever ends up in a landfill site – it always has a value and some construction materials, reinforced concrete for example, only have value because of the steel that can be recovered from them.

Some 99% of structural steelwork used in the UK is recycled, as is 94% of all steel construction products. Recycled material comprises 40% of steel manufacture globally. The amount of steel that is recycled each year – almost 500Mt – could be used to make 180 Eiffel Towers every day. The UK’s steel- framed buildings and other structures represent a strategic material resource that will benefit future generations when they reclaim it for reuse or recycling.

Sustainability demands balancing the social, economic and environmental benefits of developments – this implies, among much else, careful design, care in selecting materials and approaches to construction that minimise impacts on local communities. Steel solutions score highly on all these criteria while increasing the likelihood of projects being delivered on time and within budget. The steel sector provides a great depth of technical advice and other market support to enable designers to capitalise on these potential benefits.

Sustainability is a strength of the entire supply chain that creates the steel framing solutions that are the first choice of UK architects and structural engineers. Raw materials are sourced in an environmentally responsible way, and steel manufacturing processes have a continuous improvement culture built in.

All steel construction products benefit from off-site manufacture, which creates many sustainability benefits. Steelwork contractors’ fabrication plants allow production in factory controlled conditions, removing activities from the potentially hazardous conditions of busy construction sites. There is very little waste arising and all steel that is not used is recycled.

Steelwork contractors employ trained workforces in factory conditions. There are benefits to the welfare of the on site workforces involved in steel construction as well. There are fewer journeys to work than would be the case with in-situ produced alternatives. There is less requirement for construction workers to spend extended periods away from home. On site, experienced and trained specialist steel erectors quickly and safely assemble pre engineered, quality assured steelwork. The outcome is high quality, low defect construction with minimal waste.

Steelwork contractors are skilled at just in time delivery, which means there is little need for on site storage of materials, and deliveries to site can be timed to avoid peak periods of congestion. Local communities appreciate the reduction in deliveries by heavy lorries that is achieved, with less noise and dust overall than would otherwise be possible.

Developers value the fact that steelwork construction is fast and predictable; construction programmes are reduced and there are fewer delays to production caused by adverse weather. Steel is also the sustainable option when whole life costs are considered. Steel structures are durable and low maintenance. This means that building owners can rely on seeing a return on their investments sooner. Cost effective steel buildings generate higher initial returns, and as steel buildings are easily updated to stay looking modern and welcoming long term returns are higher.

Steel frames lend themselves to easy demountability – a key element of London’s winning bid to stage the 2012 Olympic Games. Re-using a steel frame means that a new facility can be created with very little addition to the carbon footprint.

Steel buildings provide inherently flexible clear-span spaces that can be easily and economically expanded to meet changing needs of building owners and tenants, whether it is hospitals, factories, offices, schools or shopping and leisure developments. This future proofing is especially valued by building users in rapidly developing sectors like healthcare.

As attention switches away from how to heat buildings towards recognising the carbon impact of keeping them cool, designers increasingly value the ability of steel-framed buildings as efficient stores of thermal energy, containing sufficient mass to allow designs to maximise fabric energy storage. This means excess energy can be absorbed during the day and expelled at night, which reduces the need for energy to be used to heat and cool buildings.

The steel sector has taken a lead in demonstrating its commitment to the sustainability agenda by developing a Sustainability Charter for British Constructional Steelwork Association members. The Charter sets out a coherent strategy of prioritised sustainable development objectives, against which progress is annually reviewed. Signatories commit to a wide range of sustainable practices across their operations and agree to an annual audit of their performance against the commitments made.

A multicycled material

There is virtually no such thing as waste steel – all steel has a value and it will never be knowingly sent to landfill. There is never any degradation in the quality of the material when steel is recycled.

This multicycling ability means that steel has a sustainable economic life cycle that is unrivalled by any other construction material.

Off-site on top of Mount Snowdon

Sustainability conscious clients increasingly demand off-site construction. All steel construction involves off-site construction. On some projects this virtue is a necessity however, as was the case at the new visitor centre on the summit of Mount Snowdon in North Wales.

The summit of Snowdon can be very inhospitable so the benefits of off-site fabrication, like speedy and safe erection and creation of a weather proof working area, was appreciated by the entire construction team.

All structural elements had to be brought up on the mountain railway in 14m long ‘packages’. Steelwork contractor EvadX undertook trial erections to ensure that all the elements would fit together easily once brought to site. The Hi-Point modular roof was trial installed at the Corus Shotton facility, and delivered to site in 35 segments.

Re-use designed in

Steel-framed structures can be easily disassembled and the sections re-used elsewhere. This demountability is a major sustainability virtue of steel framed structures that clients value more and more. Being able to avoid creation of white elephant structures by taking them down, completely or in part as required, and reassembling them elsewhere in the country was a key part of the winning London bid for the 2012 Olympic games.

Steel-framed structures can be easily disassembled and the sections re-used elsewhere. This demountability is a major sustainability virtue of steel framed structures that clients value more and more. Being able to avoid creation of white elephant structures by taking them down, completely or in part as required, and reassembling them elsewhere in the country was a key part of the winning London bid for the 2012 Olympic games.

Industrial buildings are now designed and built to accommodate easy re-use when buildings reach the end of their working lives, or a valuable site is needed for a new activity. Barrett Steel Buildings for example worked closely with client ProLogis Developments to design a building with eventual disassembly and re-use in mind.

The highly sustainable building, a 99m long, 10m high, 50,000ft² warehouse at ProLogis Park, Heathrow, also includes a 5,000ft² office as well as goods and entrance canopies and is let to airport operator BBA plc. Value engineering by Barrett Steel Buildings during the design stage allowed re-use potential to be maximised at no extra cost to the client.