Projects and Features

Targeting net-zero

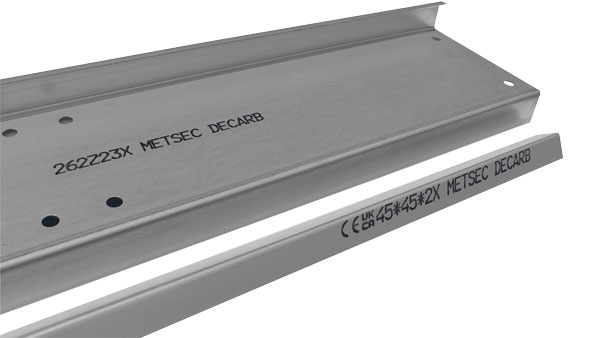

As the construction industry accelerates towards net-zero targets, voestalpine Metsec is setting new standards with its reduced carbon purlins, side rails and mezzanine sections.

Developed as part of the company’s wider decarbonisation strategy, Metsec Decarb offers significant embodied carbon savings without compromising performance or durability.

With embodied carbon levels as low as 1.25 Kg/CO²e per Kg of steel, Metsec Decarb use Electric Arc Furnace (EAF) sourced sections that make it easier for specifiers and contractors to meet sustainability goals. When compared with the blast furnace alternative, Metsec Decarb offers embodied carbon savings of around 54.7% (values accurate to EPDs issued in July 2024).

Importantly, all voestalpine Metsec Decarb products are CE and UKCA marked, backed up by rigorous testing and full traceability. Whether used in industrial, commercial, distribution or agricultural buildings, they provide a reliable, environmentally responsible alternative to conventional systems.

Metsec Decarb Z Purlins

voestalpine Metsec has already received global recognition for its drive towards a reduced carbon future by winning the Low Carbon Manufacturing Award in the Sustainable Metals and Alloys category.

The award honours our leadership in sustainable metals and alloys, advancing decarbonisation in metal construction products. It also recognises the great strides we have taken towards reducing embodied carbon in our products, not only by using reduced carbon steel in their manufacture but also through our industry-leading Net Zero Carbon initiative.

We are proud to announce we have already manufactured & delivered two Metsec Decarb projects with another expected by the end of 2025.

Metsec Decarb Reduces Embodied Carbon

A new Aldi store due to open in Pershore, Worcestershire by the end of 2025 is utilising voestalpine Metsec purlins and side rails manufactured from the company’s innovative Metsec Decarb reduced carbon steel.

The new store, located on a former indoor market site, will provide a total footprint of 1,780m2 and is being delivered by DSP Construction Management (Midlands).

In keeping with Aldi’s sustainability targets, the project incorporates many measures aimed at reducing its carbon footprint, both in construction and future operation. These include solar panels and air-source heat pumps with a heat recovery system.

The structure has been designed by Craddys Consulting, who specified voestalpine Metsec’s Decarb steel for the purlin and side rail elements of the new store. The steel frame, consisting of 70t of hot-rolled EAF steel was fabricated and installed by a steelwork contractor that partnered with voestalpine Metsec to manufacture and deliver 9.8t of cold rolled Metsec Decarb steel purlins and side rails.

voestalpine Metsec’s Decarb initiative is redefining sustainable construction by delivering high-performance steel solutions with significantly reduced embodied carbon. Through pioneering projects like Tech Foundry 3 and Aldi Pershore, Metsec demonstrates how innovative materials, strategic partnerships, and a commitment to net-zero can drive meaningful change across the built environment.

Decarbonising Innovation

Construction is under way on Tech Foundry 3 – Tech Edge West. This is the latest of three buildings providing 21,336m2 of flexible laboratory, advanced manufacturing and office space at the Harwell Science & Innovation Campus near Didcot in Oxfordshire.

The new cutting-edge Tech Box & Research & Development Space, which is being delivered by Glencar Construction, features a sawtooth roof design optimised for photovoltaic installation, photo carbonate façades for daylighting and a “fabric first” approach aimed at energy efficiency.

With sustainability at its core, the embodied carbon content of the building materials required careful consideration. Nationwide Structures designed, fabricated and erected 360t of hot-rolled EAF steel for the project, providing a significantly lower embodied carbon content to the blast furnace alternative.

The embodied carbon content of the cold-rolled purlin and side rail elements of the structure was also a key factor in reducing the structures embodied carbon levels. With lead time being a key factor, Nationwide Structures partnered with voestalpine Metsec; who currently carry the largest stock of S450 grade EAF galvanized coil in the UK; to manufacture and deliver 65 tonnes of cold-rolled purlins, side rails and accessories.

The integration of advanced steel technologies like Metsec Decarb, is why the project stands as a compelling example of how collaborative design, efficient delivery and responsible material selection can redefine the possibilities of modern construction, paving the way towards a more sustainable future.

vosetalpine Metsec

is a Gold sponsor of

Steel for Life