Technical

Steel – the never ending process

The sustainability benefits of steel in terms of multi-cycling are becoming more widely appreciated, says John Dowling, BCSA Manager, Sustainability.

Steel is the world’s most multicycled material. It never loses its value and enjoys a sustainable economic life cycle that is unrivalled by any other construction material. All steel has a value, whether it is being re-used or recycled with around 500M tonnes of steel recycled globally every year. Current UK recovery rates are 99% for structural steelwork, and 94% for all steel construction products. Steel has always had a sound sustainability case and can easily be recycled or remanufactured into new products with no loss in fundamental properties. Its magnetic properties mean that it can be efficiently segregated from mixed waste streams and fed back into the system.

The outstanding multi-cycling performance of steel is well recognised, and its intrinsic value as a scrap material means it is always in demand for the production of new steel. Scrap that is collected for recycling is material that does not have to be managed as a waste or sent to landfill. It is a valuable resource that is converted into value-added commodities.

Perhaps even more importantly, the recycling of steel already in circulation saves not only the planet’s valuable resources, but offsets primary production processes and their associated environmental impacts and energy consumption required to mine, crush, grind and otherwise metallurgically process virgin ore. Recycling also increases the material and energy efficiency of product systems throughout the life cycle via saving energy and associated greenhouse gas emissions through less energy intensive reprocessing and thus is good management practice.

Steel scrap can be blended, through the recycling process, to produce different types of steel – both grade and products – as demand dictates. For example, steel from redundant industrial machinery can be used in the manufacture of more contemporary products such as cars or white goods which, in turn, can be recycled into new, maybe as yet undiscovered, applications in the future.

There are thousands of different grades of steel available, each tailored to specific applications in sectors as diverse as packaging, engineering, white goods, vehicles and construction. Construction is the largest market sector for steel in the UK, accounting for 29% of consumption in 2008(1).

All new steel products in use today contain a proportion of recycled content. While these products can have been recycled through one or many previous uses, it will at the start of its life cycle been produced using iron ore. As long as steel recycling continues the life of the steel within a product is infinite, and becomes merely parts of the large life cycle of the material.

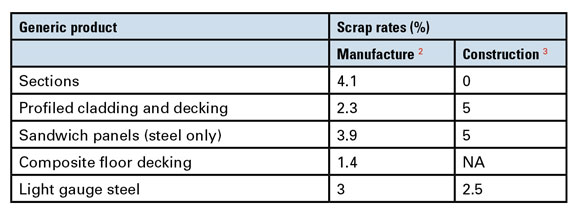

An unrivalled sustainability strength of steel is its ability to be repeatedly re-used or recycled without any degradation in the quality of the material. Other materials are often recycled only once before downgrading, and eventually find their way to landfill. Scrap is produced during the construction and refurbishment of buildings and when they are ultimately demolished and therefore material becomes available for recycling at each of these stages. As prefabricated products and systems, scrap from the manufacture of steel construction products is easily collected and segregated for recycling and, on the construction site, steel products generate very low or zero scrap. See Table 1.

While the amount of scrap steel that is collected for recycling is known, it is much more difficult to establish the amount of scrap steel arising from the construction and demolition of buildings. In the UK in 2008, 11.5mt of scrap steel were recovered (from all market sectors) for recycling. It is estimated that construction steel accounts for 8% of this total. This proportion is much lower than the share of steel going into construction (29%) and this reflects the longevity of steel construction products, implying that the stock of steel in UK buildings and infrastructure is increasing.

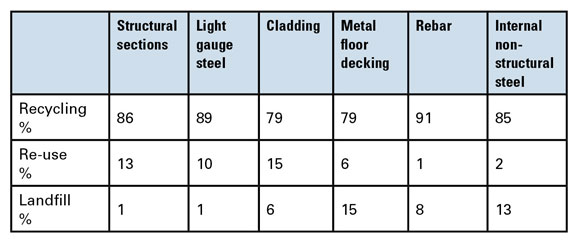

To establish recycling rates for steel construction products, a detailed material flow analysis (MFA) was undertaken in 2003(4). The results were validated as part of a larger MFA study of the UK steel sector(5).

References:

1. ISSB, 2010

2. Life cycle assessment (LCA) for steel construction, European Commission,

EUR 20570 EN

3. Site wastage rates used for the Green Guide to Specification, BRE

4. An environmental and material flow analysis of the UK steel construction sector. J. Ley, 2003.

5. Iron, steel and aluminium in the UK: material flows and their economic dimensions. Policy Studies Institute, London. Centre for Environmental Strategy, University of Surrey, 2004.

New BCSA office puts sustainability into practice

The BCSA’s regional Yorkshire office demonstrated steel’s sustainability credentials as the building was constructed with 82t of re-used steelwork.

The office development’s portal framed 1,800m² structure was built entirely with steel from an old warehouse which was redeveloped. All the sections were disassembled and then refabricated in to a new frame.

Recovered Teeside steel

Recycled steel turns up virtually everywhere. When Corus demolished a redundant open hearth steel plant, that had come to the end of its useful life in 2004, the 20,000 tonnes of recovered steel were tracked through the recycling process to its new uses.

Structural sections went to Heathrow Terminal 5 and the new stand at the Oval. Some was used in the manufacture of steel plate for the construction of buildings over Paddington railway station in London.

More plate was fabricated into large girders used on the construction of the A249 bridge to the Isle of Sheppey in Kent. And some was even used in the manufacture of galvanised strip steel to make light steel-framed houses. Other uses included copper-plated coins and automotive parts.

Recycling this steel saved enough energy to supply 3,700 households with all their energy requirements for a year