Technical

Steel design since 1932

Successive editions of BS 449 illustrate significant changes in steel design and practice over the last 90 years. For a recent project, the design rules since 1932 were reviewed. David Brown of the SCI identifies some of the more interesting features.

Introduction

No-one can have escaped the fact that minimising embodied carbon in construction is a really important part of the sustainability agenda. In structural steelwork, one opportunity to save both carbon and money is to reuse steelwork. Not to recycle, but to carefully recover beams and columns (Figure 1) during demolition, refabricate and erect into new structures. It is said that around 70% of current enquiries for structural steelwork reflect this desire to reuse in some form. In 2019, SCI published P4271 which has become the “go-to” guide on steel reuse – if there is any doubt, see The Structural Engineer2 of March 2023.

P427 has a limited scope, covering steel used in construction after 1970. Material characteristics (such as yield and ultimate strengths) are available from around that time, which were then used in the determination of material factors recommended in P427. As interest in reuse grew, extending the advice to cover the reuse of ‘older’ steel became important. This advice has now been published in P4403. As part of the work leading to this supplementary guidance, the design standards and material standards of the time were reviewed, revealing some historically interesting details. The start date was selected as 1932, since this was when BS 449 was first published.

Buckling – in the beginning

Early in the development of P440, the overall objective was to ensure that an ‘old’ piece of steel designed to the Eurocodes would not be credited with any more resistance than it would have at first use. It might be said that the steel never knew which code it was designed to, and that its structural mechanics has not changed over time – so if we know ‘more’ now, why not use that knowledge? However, it is clear that steel production may have changed over the last 100 years, perhaps especially during the war years when steel was in short supply. The decision taken was that the buckling codes of the time were appropriate for the steel of the time, and that the advice in P440 should be conservative. That decision resulted in a detailed review of the buckling rules in BS 449 since 1932. Surprisingly, the earliest edition at the SCI was from 1935 – The IStructE library was able to assist.

Compression

The first issue of BS 449 in 1932 had both a formula and a chart to determine the “Working stresses on Pillars and on Compression Members”. Designers will recognise the Perry-Robertson expression also seen in BS 5950 and its algebraic equivalent in the Eurocode. In that sense, not much change over the last 100 years. The 1932 edition also included a table of effective lengths, noting that the values were “in respect of typical cases only and embody the general principles which should be employed in assessing the appropriate value for any particular pillar”. Thus the designer was left to reach their own decision, in some cases assessing the “efficiency of the imperfect restraint”. The length of a member “adequately restrained at both ends in position and direction” was to be taken as 0.75 of the actual pillar length. By the 1935 edition, the familiar values of 0.7 and 0.85 appeared accompanied by guidance on how the end restraint could be assessed. In the Eurocode, the designer must decide what the buckling length is without guidance, which some might say does not show progress.

The 1932 and 1935 editions introduce the design model for columns in braced construction, with beams applying moments based on the eccentricity of the reaction. Those moments may be divided proportionally to the stiffness of the lengths above and below. By 1948 the assumed eccentricity of the reaction was tabulated and the simplification introduced that if the stiffnesses of the lengths above and below did not exceed a ratio of 1.5, the moment could be divided equally. It was not until the 1959 edition when the eccentricity was defined as 4 inches from the face of the section, which is the 100 mm still used today.

Lateral-torsional buckling

In the 1932 edition of BS 449, lateral torsional buckling was simplicity itself. There was no reference to lateral torsional buckling, but rules are given for uncased beams without lateral support. The allowable stress on the extreme fibre of an uncased beam was given in Tons/in² by:

If the length L was less than 20b then the allowable stress was 8 Tons/in². This is what we would recognise as the plateau. Finally, the L/b ratio could not exceed 50.

Figure 2 shows the comparison for a 305 × 165 × 40 UB. The allowable stress has been converted into a non-dimensional reduction factor.

The plateau extends to 20 × 165 = 3300 mm

No values are given past a length of 50 × 165 = 8250 mm

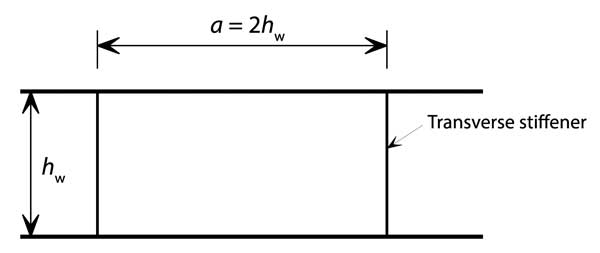

Figure 2 also shows the elastic critical stress, which has been calculated from Mcr and the reduction factor according to BS EN 1993-1-1 (the special method for rolled sections). The BS 449 resistance looks optimistic, extending out to a plateau of 0.8 in Eurocode terms, and past the elastic critical buckling curve.

The formula for lateral torsional buckling resistance had changed by 1948. The bending stress was given (in Tons/in²) by:

but not exceeding 10.

where K₁ is a bending stress factor, depending on the ratio

Tall, narrow sections have a lower value of K₁.

Figure 3 includes the 1948 buckling curve for the same 305 × 165 × 40 UB, indicating an even more optimistic buckling curve.

The ratio

and the K₁ factor becomes 1.415.

The length of the plateau is given by (1000 × 1.415 × 38.6)/10 = 5462 mm, or in Eurocode terms, a plateau length of about 1.23 (contrast with the Eurocode maximum value of 0.4).

The 1969 edition of BS 449 pulled the curve back to the 1932 line, and also limited the resistance to the elastic critical value. The final drama appeared when Amendment 8 to BS 449 was issued in 1989 (four years after BS 5950 was first issued), and the lateral torsional buckling curves were pulled back further and broadly align with the Eurocode curves. Note that BS 449 made no allowance for a non-uniform bending moment diagram. The approach taken in P440, as with compression, was to formulate a curve that is (just) conservative compared to all editions of BS 449.

Connection methods

The 1932 edition of BS 449 is silent on welding, describing rivets, “turned bolts of driving fit” and “black bolts” for work in both the fabrication works and on site. Three years later, the 1935 edition notes welding as an option in both the workshop and on site “when so specified by the Engineer or Purchaser”. No design guidance for welds was included.

By the time the 1948 edition was published, welding was extensively addressed with rules for butt welds, fillet welds and (in Addendum No 1) welding round the ends of hollow sections.

Welding of ‘early’ steel is possible, although better practice would be to form joints as anticipated at the time – using bolts. Double angle cleats would be an appropriate connection for the ends of simply supported beams, for example. If welding is considered, the advice of the Responsible Welding Coordinator will be needed and welding trials should be considered.

Brittle fracture

The various editions of both the design standard and the material standards chart the advancing knowledge about the risk of brittle fracture. Before the Second World War, there was little interest in impact toughness in building structures. This changed dramatically with the losses of “Liberty ships” during the war, when the problems of low temperatures, high stress and stress concentrations led to around 1500 instances of significant brittle fractures. The material standard for structural steel, BS 15, had no impact toughness requirements specified in the 1948 or 1961 editions, so it seems that after the war the construction industry did not treat the issue with urgency.

It was not until the 1959 edition of BS 449 that the standard included a note that whilst welded structures of steel to BS 15 are normally satisfactory, brittle fracture was a possible failure mode in certain circumstances. Amendment 6 of 1966 included impact test requirements for the first time. Steel designers will recognise the comprehensive requirements in BS 5950 of 1985, and the even more involved considerations within EN 1993-1-10, which represent a huge change from perhaps less informed days.

One of the key recommendations in P440 is that ‘early’ steel may have low toughness properties, and that even subgrade JR cannot be assumed.

Reducing scope – but increasing page count

The early editions of BS 449 covered the design of the entire building, including design guidance for other materials such as masonry, concrete and mortar. The standards also included imposed loading (50lb/ft² for office floors, which is 2.4 kN/m², so quite consistent – or unchanged over 90 years despite changing use of office space?) and wind loading.

In 1932, wind loading is covered in two paragraphs. A minimum of 15lb/ft² (0.7 kN/m²) was stipulated with a further provision to be made on the sea coast and similarly exposed situations (but no advice on what that provision should be). If the building height was less than twice its width, wind pressure could be neglected altogether, provided the building was “adequately stiffened by floors and walls”. By 1948, the clauses covering wind loads ran to about six pages, including internal pressures, local pressures, multi-span roofs and different categories of terrain. By 1959, BS 449 – which was always in A5 format – focussed solely on steelwork design but the page count had still grown from 33 pages in 1932 to 87 pages in 1948 and to 115 pages in 1959. One wonders what the designers of the 1930s would make of our current design standards.

References

- Brown, D.G. Pimentel, R. J. Sansom, M. R.

Structural Steel Reuse (P427)

SCI, 2019 - The Structural Engineer

March 2023, Volume 01, Issue 3

The Institution of Structural Engineers, 2023 - Brown, D. G. Dougherty, L. A.

Reuse of pre-1970 steelwork: Supplement to P427

SCI, 2023