Projects and Features

Shanghai Gate

A flamboyant gateway marks the entrance to the new Central Park in the developing area of Pudong, Shanghai. John Rushton reports.

FACT FILE: Shanghai Gate

Concept Architect: Jestico + Whiles (J&W) – Tom Jestico

Project Architect and Engineers: Tonji University, Shanghai

Engineer: Peter Brett Associates

Pudong is an area on the east side of the Huangpu River. A new city for two million is being developed on 500 sq km, dwarfing the buildings on old Shanghai opposite.

The waterfront includes the International Hotel, an early steel 20-storey building. Built in 1934, it was the highest residential building in Old China. As part of the new spectacular urban development, Pudong’s principal park has been constructed to meet the leisure needs of the inhabitants. Built on polluted marshes and smallholdings Central Park is Pudong’s version of Hyde Park in London.

The Pudong Land Development Co engaged Land Use Consultants after an international competition. The English Landscape tradition particularly appealed to the client in contrast to more formal traditional Chinese landscaping. Jestico & Whiles (J&W) architects were appointed as the designer of the Park Buildings which varied from small first aid stations, 500 seat restaurants, pavilions, a folk museum, to a bio-climatic building and included the main gate structure housing security, ticket issue and washrooms.

Brief History – iron

Historically, metallurgical and building techniques have been well advanced in China. Early use of iron includes an iron chain bridge (Lanjin bridge) built in AD 58-75 in the Yunnan Province. Later chain bridges include Jihong Bridge, 113m long built during the Ming Dynasty (AD 1487) and the Luding Bridge, 100m clear span built during the Qing Dynasty (AD 1705).

During a particularly prosperous period approximately 1,000 years ago memorial iron towers were built with religious functions, the Guangxiasi Iron Tower in Guangzhou and the Yuquansi Iron Tower in Huba Province 17.9m high (ref 1).

Gates in China

The visitor to China cannot fail to notice that gate structures have been significant symbols of power and wealth. From the Bedaling Water Fort gate on the Great Wall to the entrance of the Forbidden City displaying pictures of past chairmen of the Party.

Gates such as the Supreme Harmony Gate and the Chengzhen Gate are architectural masterpieces. These constructions of timber, masonry and clay tiles are superb expressions of symmetry, durability and function. The new Central Park Gateway Building has a challenging heritage to follow.

Initial Roof Concepts, new Gateway building

Preliminary architectural sketches had been produced with a minimal client brief. They showed four columns supporting a main canopy roof that over sailed a lower level of similar shaped canopies. The roof finish was anticipated to be copper.

A steel framed primary structure was an obvious choice. Copper roof covering suggested that a system of timber joists with a ply top and soffit could be formed into the curved shapes required. This also would allow most of the main steel canopy framing to be encased providing a smooth soffit.

A hyperbolic paraboloid module was considered. Four modules in a typical structural bay with horizontal meeting edges offered a starter for the mathematical expression of the shape sketched by J&W.

The kiosks’ canopy roof is 5m wide having five 7.2m bays on one side and a double bay on the opposite side. In addition, 7.2m long cantilevers extend under the main canopy and from each end of the kiosks. The structural bay is defined by 5m long horizontals supporting a level spine beam on the centre line spanning 7.2m. The edges of the canopy are defined by a sinusoidal waveform. Its peak is at 7.2m intervals mid way between supports and level with the centre line beam at +4.53m.

The structural cross section initially envisaged was a series of secondary straight members at relatively close centres to support the ply deck. They would be supported off the central horizontal spine and the perimeter sinusoidal member. However a roof shape curving in two directions was preferred. This implied that each concave secondary member would be curved to a different shape within each half bay of 5 x 3.6m.

Above the kiosks’ canopy is the main canopy. It is 34 x 8m wide and has a level spine beam on the centreline at +5.60m. The sinusoidal edges are aligned with an axis on the same level of the spine. This forms a roof that rises above the spine beam level at the ends of the canopy. Secondary members would be both concave and convex to form the required shape.

Framing Concept

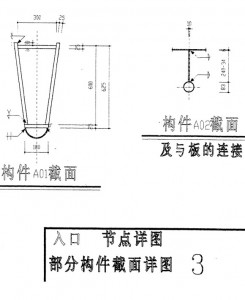

The kiosk canopy had “fixed” base posts supporting, 5m long 200mm fabricated square cranked beams. The central spine beam /cantilever was a 350 x 170mm fabricated section with a sinusoidal, 180mm fabricated square edge member. Overall roof thickness, including ply skins, would be about 300mm.

The main 34m long canopy had four “fixed” base posts with masts extending 15m above ground level. Cables were connected to the central spine, 5m from its free end. 20mm diameter ties sufficed in tension but a tie down would be required on the propped cantilever to counter wind uplift on the lightweight roof construction. The total weight of the main canopy structure was approx 35 tonnes including copper sheeting and timber.

Procurement

The client, Pudong Land Development (Holding) Co, invited J&W and ourselves out to Shanghai to discuss procurement of the Gateway Building after initial costing exercises had suggested that manufacture in Europe and export/erection in China would be prohibitively costly.

We were to find on arrival in Shanghai that a parallel team of engineers and architects from Tonji University had been set up. Quite a few changes would need to be incorporated into the design to allow them to construct it to suit their “procurement chain”.

In addition to their translator our local representative was needed for the daylong meetings with attendees. Usually totalling in excess of 20 there were representatives from the client, his urban planners, engineers, architects and steel workers from the Hudong Shipyard Group.

Design and “Construction lead” adjustments

Doubly curved copper roofing could not be sourced without special importation arrangements. Wood or woodworking construction skills were locally not available. After a day of discussion the presence of steelworkers from a shipyard was clarified: the intention was to make the gate in solid steel.

Clearly double curved plate work, as used on ships hulls, was well within the capability of the workforce.

Intensive design development of the details followed. It soon became apparent that tie down arrangements for the canopies could be omitted due to the structure weight now being introduced.

Workmanship was initially of concern. Previous studies (ref 2) of the Chinese market had indicated that UK standards of quality might not be easily achievable. However the ability of erection companies to carry out complex site fabrication was also acknowledged as well as a high level of skill and a large workforce.

By the end of a week virtually all the key fabrication details had been developed and agreed.

The Constructed Gate

The overall weight of the main canopy, with a 6mm thick shaped steel plate roof has increased to approximately 60 tonnes. One important advantage of adopting a steel plate roof was that the canopy edges could be reduced to a thickness of 100mm at the tip of the stiffeners that were spaced at 800mm and cantilevered from the main central spine beam. The roof stiffening plate has a 83mm tube. The fabricators accepted this, as we were anxious to achieve a canopy underside detail tolerant of any misalignments of the stiffeners.

The mast size is now a 245mm CHS and lower section stiffening fins are changed from 20mm to 2 No 25mm thick plate. Joints in the 6mm roof plate co-ordinate with the stiffeners but welds are visible from above.

We left Shanghai with a lingering doubt over the top surface welding detail. A passing remark from the client that he would send photographs of the completed structure meant we were not likely to do an inspection during construction. From the cultural viewpoint integration with a completely different approach to the design and construction processes in China was a fascinating experience. We were thankful, when the photographs arrived, to see that the gate looked as impressive as we had hoped.

John Rushton is a Partner of Peter Brett Associates.

References

- L. Henlan, L. Wanzhong, C. Luru; “A Review of China’s Steel Construction Industry”; Structural Steel PSSC ’95 4th Pacific Structural Steel Conference Vol. 1 Steel Structure

- A.F. Collins; Chinese Constructional Steelwork Industry; BCSA, 1994