50 & 20 Years Ago

Offshore quarters

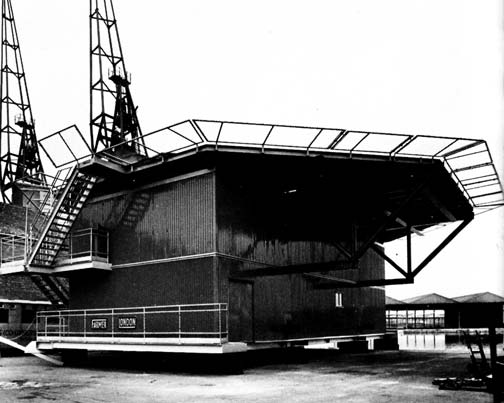

Conditions are tough on an oil-drilling rig. The work is arduous and the weather can be foul. Off-duty the crew therefore need comfortable quarters. That these are now being provided can be seen from this new development from Farmer Offshore Ltd which is described by Mr H. Snaith of CONSTRADO

Already internationally known for their work in furnaces, structural steel, and in the oil and petrochemical plant field, S. W. Farmer & Son Ltd, structural and mechanical engineers, of Courthill Road, Lewisham, London SE13, recently formed a new company – Farmer Offshore Ltd – to exploit the new, expanding market of producing equipment for offshore oil-rig platforms.

Offshore building work is carried out at the Farmer assembly centre at London Docks where they have extensive storage facilities coupled with waterside access with a quayside water depth of 9m (adequate for oceangoing barges). Each building, whether a generator building, service building, or crew quarters, is designed to integrate into the individual rig services system and connects direct to plumbing, piping, power, etc, with minimal external routing. All buildings are supplied pre-wired and complete with all internal fittings and equipment.

General construction

The main structural work is carried out by Farmer staff, but fitting out is carried out by sub-contractors experienced in oil-rig work. Equipment and accommodation buildings incorporate steel skid bases and all structures are supplied with single-point crane lift slings or frames. Walls and roofs are of sandwich construction steel or aluminium cladding with a U-value of 0.1. Doors and flashings are system built to high standards. Structures are heated and ventilated by independent automatic ventilating louvre systems so that they may integrate into the existing platform air-pressure system. Dehumidifiers, gas detectors, and fire extinguishers are also incorporated into the design.

Turbo-generators, insulated exhaust systems, stand-by diesel generators are installed and tested by Farmer. The generator buildings contain motor control panels and station batteries. Switchgear buildings have relay panels, navigation aids, radio rooms, telemetry measuring panels and rig-savers, all pre-wired. Auxiliary buildings are supplied to provide storage, workshop and general service areas, or to house battery racks or emergency power generation plant. The framework is, of course, steel. It is totally welded, which is 60 per cent weld tested.

Living-quarters

It will be appreciated how extreme are the climatic and meteorological conditions experienced in the North Sea. Living-quarters must be properly insulated and completely sea-proof, and capable of standing up to high wind pressures and varying temperatures. Particular attention must be paid to sealing of doors and openings and the fastening of claddings.

Living-quarters of varying weights up to 300 tonnes with provision for living accommodation for 16 to 40 men, according to rig platform requirements, are supplied in single or multi-storey designs, the roofs of which form helidecks.

Typical of Farmer construction and design was the recent completion of an order for a helicopter-decked crew accommodation building. The order for this was placed in the middle of December 1970, and dispatch date programmed was for the end of May 1971. This was a very tight schedule indeed.

The structure provides living accommodation for 20 men and enables them to live in a safe atmosphere away from the hazards of the production platform. The building has its own emergency lighting system as well as gas and fire detectors, and thus provides an intrinsically safe environment.

The building is air-conditioned and fitted with a kitchen, lounge and dining-room, utility-rooms, equipment stores, etc. The upper storey (the building is of two-storey construction) has bedrooms fitted with individual shower and toilet units and has sound-proofed shift-rooms.

The total structure weighed 160 tons when shipped by sea barge for direct installation on to the offshore platform and a complete service of offshore commissioning and testing was supplied. The structure, which is virtually a miniature hotel and airport, was loaded out on to an ocean-going barge by the ‘Mammoth’ crane of the PLA, towed out to the North Sea on May 28, and landed in position on May 30.

Specification

The frame was constructed of steel. It was a totally welded fabrication, 60 per cent weld tested, and prefabricated in large sections at Farmer workshops and assembled at the dockside.

Cladding was purpose made from 1in Styroform, backed internally with galvanized sheet and faced with a profiled marine aluminium to specification colour, in 24g. Cladding was fastened by stainless-steel rivets and cladding laps were a minimum of 6in. Main fixing bolts at 2ft 6in centres were connected to the structural rails.

Internal partitions were in 2in and 3in thick Styroform backed both sides with Formica in grey ground colour, but yellow in the bedrooms.

Stainless steel was used extensively. The complete galley was fitted in stainless steel incorporating cabinets, worktops, deep fry, and cooker.

All stairways and walkways were galvanized after manufacture with non-slip open-type grating and treads. Navigational light supports, walkways light supports, and safety capsule supports were all built into the walkway steelwork.

Dimensions

Height of complete structure was 22ft. The living quarters on plan were 25ft wide x 60ft long. The helideck area was 65ft overall the helideck, and 72ft overall the safety-nets.

Accommodation

These comprised one equipment-store, one food-store, one heat- and ventilating-room, a galley, radio-room, one changing-room, one dining-room/lounge, two 2-man rooms, three 4-man rooms, two shift-rooms.

Services and fittings

The comfort of the crew is well cared for. Services and equipment include a washing-machine with matching dryer, refrigerator, range-oven, deep fry, Bain Marie, griller, deep freeze, ten double bunks, twenty wardrobes and twenty lockers.

From Building with Steel, November 1971