Profile

Kingspan backs off-site boom

After several false starts, could the tide finally be turning for off-site construction? Kingspan thinks so, and is backing its hunch with substantial investments to produce systems which will be fully accredited, reports Nick Barrett.

Off-site construction methods look like coming into their own over the next few years if the government’s ambitious accommodation, education and healthcare building targets are to be met. Nobody seems to know where the Deputy Prime Minister’s fabled £60,000 house is going to come from, but traditional approaches, it is widely agreed, stand no chance of delivering the quality or quantity needed in the timescales required. Innovative approaches are called for and will surely have to involve at least a substantial off-site element.

North Yorkshire based Kingspan Metl-Con has made what is claimed to be the industry’s biggest investment yet in the manufacturing equipment and engineering accreditation of products which will be needed if UK construction is to undergo the transformation from a site based industry to one in which off-site, factory based solutions dominate. The demand might yet turn out to be so much political hot air, but Kingspan is convinced enough to have invested £9.5M in new roll forming production lines dedicated to cold form steel sections, which has just come on stream.

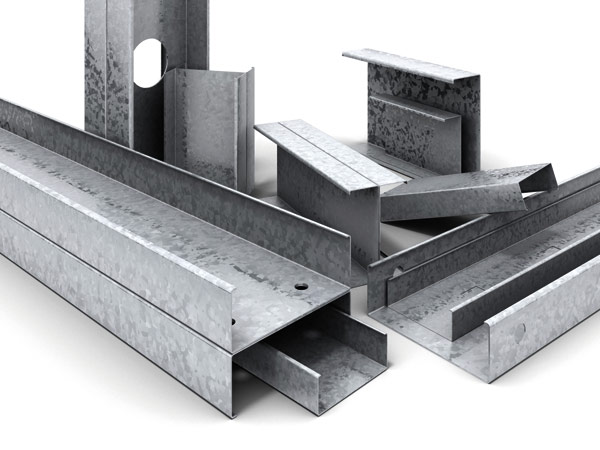

The United States sourced production line is state of the art. “There is nothing like it in the UK or elsewhere in Europe,” says Kingspan’s Off-site Sales and Marketing Manager Gary Crosby. “We have a capacity from just these machines of some 35,000 steel frames a year from a normal shift, so we could double that with shift working, and we have plenty of room to expand on our site.” The building which houses the plant is a massive 368m long and 32m wide, with overhead cranes capable of lifting 20 tonnes. Galvanised sections in thicknesses of 0.7mm to 4.0mm, in section depths of 70mm to 450mm, can be produced.

“We can produce to tolerances of 0.5mm, which is far in excess of what the site based industry is used to,” says Mr Crosby. The new line is fully automated and flexible. It allows rapid changing from coil to coil and from one section size to another. “There is little downtime whereas some of our rivals spend as much time making changes as they do actually rolling.”

A crucial element in the Kingspan recipe, one which has been conspicuously lacking from off-site related efforts in the past, is substantial engineering input. Kingspan’s products are to be fully accredited, with input from the Building Research Establishment and consultant Arup.

Multi deck steel flooring from Kingspan’s traditional product range was provided for this 11 storey twin tower office in Arnhem, Netherlands

Off-site has stalled over the past 10 years or so, for a variety of reasons, some to do with demand and others to do with the industry’s readiness to invest to meet a demand which remained uncertain. Mr Crosby says the construction industry failed to take the right approach to a cautious marketplace. “Nobody has approached it wholeheartedly before from the standpoint of a fully accredited system. In the past suppliers have just assembled components. But you need to supply the market with data on all the qualities of the product, like acoustics, thermal performance, and structural performance. We are accrediting the entire system. Arup will help us produce the first fully accredited system for frames and facades. This has been the downfall of modular approaches in the past. We will provide BRE accreditation and certification, along with quality assurance, guarantees and warranties.”

Software and architectural design packages will be supplied to key partners like architects. Customer requirements can be directly input to the manufacturing plant which will mean shorter lead times. The idea is to make the system easy to use, so software investment is crucial. Designs can be simply transferred to the manufacturing plant.

Kingspan’s aim is to develop its off-site business away from being simply a supplier of components to a fragmented market, towards being a key player in the target markets. The plan has three stages. First, the architectural facade systems are launched this month, providing conventional construction, render systems, ventilated rainscreen systems and insulated panel systems. This involves creation of a 600 page facade handbook containing some 500 construction details. It is designed as a technical handbook for specifiers. “All traditional architectural facades are covered,” says Mr Crosby.

Phase two concerns cold rolled structural framing systems and structural framing sections. These will be introduced in the second quarter of 2005. Various footprints and quick erection compatible with all facades will be possible. “This will all be fully accredited.” stresses Crosby, “underpinned by engineering input from Arup. A detailed accreditation programme through the Building Research Establishment and design work from Arup will accelerate the engineering programme.” The cost of all the technical input to back up the systems is understood to be in excess of £1M.

Kingspan reckons it can go to 10 storeys with its structural systems, and expect to be able to go beyond that in due course. Combining cold with hot rolled sections means 14 storeys can be done now.

Finally, at the end of the third quarter of 2005 Kingspan will launch its space systems, targeting education, healthcare and single living accommodation.

Kingspan sees off-site becoming a main driver of the business. “We aim to fully develop the manufacturing site and to be a leader in driving the off-site market. There is massive interest from main contractors, government, local authorities – across the board.

“The time is right for off-site, we are certain. There have been false starts before but the market conditions are right and we and our partners are bringing all the construction elements together now.”

Kingspan Metl-Con is a stock market listed company with a turnover of some £500M, employing 400 at its Sherburn site and 3,500 worldwide. Some 80% of employees are in the UK and Ireland. Some 50,000 tonnes of cold formed steel is output a year. Its biggest single market is the United Kingdom.

The company was founded in 1949 as Ward Brothers (Sherburn) Ltd, manufacturing agricultural implements and later Dutch Barns. In 1970 a Building Components division was formed to manufacture products like purlins and rails.

By 1976 it had started making single skin cladding profiles and customers could have one of three variants, all one metre wide. By 1987 expansion was started into composite cladding panel manufacture for roofs and walls. Profiled metal floor decking was soon added to the product range.

In 1997 the manufacturing arm split from Ward Contracting which became Atlas Ward Structures, which still occupies an adjacent site in Sherburn. The year 2002 saw the launch of Topdek, a single ply roofing panel. Panel systems have been the core of the Kingspan business in recent years. In 2004 there was an internal company split of the Structural Products division from the roofing and cladding panels business. The Off-site business was launched in 2004 at Interbuild.

The first major jobs are already running off the new production line. One is for Dane Architectural for frames for a residential and offices complex in Liverpool called the Unity Building. This is a 30 storey structure for which Kingspan is supplying its architectural facades. “We deliver complete units to site, frames with substrate board, insulation and facade support system,” says Mr Crosby.

Kingspan is prototyping two school projects for Essex County Council, in conjunction with Pyramid Building Systems, Kingspan’s construction partner, and consultant WS Atkins. ‘This is an alternative to the traditional temporary buildings which growing schools often have need of. Instead of those we provide permanent structures which will have a lifespan of some 60 years for the frame and perhaps 30 years for the facades. We deliver flat pack frames to Pyramid who fit drywalling, and all plumbing and electricals and deliver the nearly completed classrooms to site for quick assembly. ‘

Healthcare projects include one just finishing for the John Radcliffe Hospital in Oxford. Over 500 half tonne cold rolled frames to support facades have been supplied here. Some of these were supplied from Kingspan’s older production line and some off the new line.