50 & 20 Years Ago

Frontage made young

Introduction

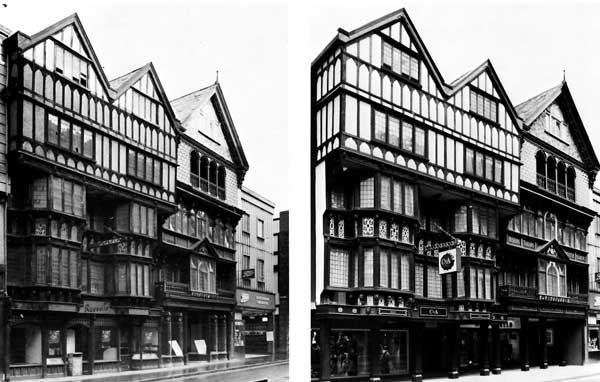

For its size there can be few cities in the country that are more richly endowed with old buildings than Exeter. It is a town of bustling shopping streets mixed with quiet alleyways, and modern architecture mixed with that of our Tudor ancestors. Exeter has gone to considerable lengths to preserve its heritage, a 600-year-old timbered house was moved 75 yards to make way for road improvements, the stone Guildhall, one of the oldest municipal buildings in the country, is being pinned together and reappointed, and numerous examples of timbered buildings altered to provide shopping facilities exist in central Exeter. The most recent of these and perhaps from the structural point of view, the most extensive and challenging, has recently been completed in the High Street as part of the new C&A Modes and Austin Reed stores in the city.

The frontages that have been preserved are two neighbouring buildings of differing age, style, construction and condition. The C&A portion of the frontage to the left hand of the photograph (Fig. 1) dates from the end of the sixteenth century. In early days, Mr Simon Snow, an eminent city merchant, Member of Parliament, and Mayor in 1653, resided here, but in recent years it has been converted for offices and shop use. The last occupier had closed off the top three of the five storeys, and this upper section of the building had suffered considerably from the ravages of weather, rot, neglect and timber beetle. The roof was in particularly poor condition and any scheme for renovation had to include replacement of the roof timbers and slates.

The Austin Reed frontage dates from about 1650 to 1670 and was doubtless built by one of the wealthy city merchants, who had by this time commenced to forsake the hitherto more fashionable lower end of the town and move higher up. The varied colouring and loud style of architecture present an interesting contrast to the rest of the shopping street.

The street front was restored in 1858 and considerable alterations were also made inside the building in 1883. Generally its state of repair was good, although settlement of the party wall with neighbouring Boots’ chemist shop had caused a lean in that direction and distress in some of the internal members. During the rebuilding of Boots, some ten years ago, the planning of the shop had allowed temporary bracing to be provided to arrest the lean of the Austin Reed premises, but any reconstruction of the latter would of necessity allow the removal of these shores.

In order to ease the pedestrian bottle-neck in this part of the High Street, a condition of planning approval for the new development was that a pedestrian way be formed through the ground floor at the front of the existing and future structures. This meant that the existing flank walls, which carried much of the old structure down to the foundations would have to be removed from ground to first floor.

Organization of building work

C&A Modes and the Austin Reed Group agreed to develop concurrently and the consultant team was appointed for both shops. The contract for the support and renovation of the façades and demolition and redevelopment of the remainder of the site was negotiated with Sleeman Construction of Exeter, so that they could contribute to discussions on the retention of the frontages and other critical aspects of the scheme.

A survey with accurate floor levels was made of the old buildings together with an initial examination of the existing framework. From this survey, it became clear that the poor condition of the C&A section required the retention of a portion of the existing floors in order to maintain the stiffness of the frontage, otherwise an extensive system of temporary shores would be necessary. Several schemes were produced and these were compared as far as possible for safety, ease and speed of erection, cost and obstruction of pavement. Basically, the schemes were of two types:

(a) Temporary shoring to allow demolition on the remainder of the site and construction of the permanent support behind the frontage as the rest of the development proceeded.

(b) Construction of the permanent framework immediately behind the frontage before or during demolition on the remainder of the site and connection of this framework to the main structure as the new development was constructed.

Since temporary possessions of the High Street would be required and considerable obstruction to traffic and pedestrians would result from any variation of scheme (a), it was agreed to adopt alternative (b), constructing a steel framework inside the existing buildings. This method did have two disadvantages, namely, that the existing floor levels did not correspond with those proposed, so the space occupied by the steelwork frame would be lost, and, secondly, construction time would mostly be longer.

Discussions were held with the Exeter City Council concerning obstruction to the pavements, column layout and treatment at ground floor. With the guidelines agreed, meetings were convened with the Architect, the Main Contractor and the Steelwork Fabricators, F. Parkin and Sons of Exeter. As a result of these meetings, the Consulting Engineer’s proposals were finalized to suit the planning requirements of the Architect and the construction methods of the Main Contractor. A detailed investigation of the existing structure was commenced, which entailed cutting holes in floors and walls to confirm the suitability of the proposed column and beam centres, and removal of internal panelling to investigate more fully the extent of deterioration.

When this had been done, the final design was prepared and a building programme drawn up. Demolition of the remainder of the site was programmed to take six weeks and therefore it was intended to commence the frontage support steelwork two weeks earlier, so that by the time the demolition contractors had progressed to the front of the site where the façade was to be retained the new structure would be in position to stabilize the frontage. However, unexpected difficulties led to problems with regard to phasing the work relative to the main building contract.

The scheme adopted

Basically, from the engineering point of view, a structure had to be designed to carry the vertical loads from the buildings to be retained together with those from the new construction behind the frontage, and be able to withstand wind loads on the frontage in the post-demolition stage. Also it had to be capable of being constructed by manhandling the components, as very little lifting equipment could be accommodated inside the confines of the old buildings.

All the members of the structure were designed generously, as the loading of any particular member could depend on the means of cramping the existing fabric to the new steelwork, and generous sizing would permit last minute adjustments to the positions of cramps to be made.

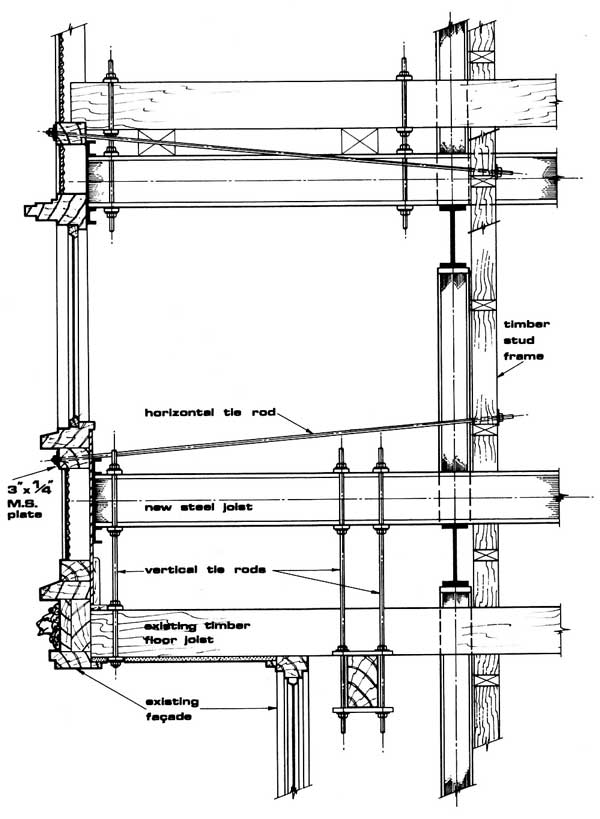

The main framework consists of two rows of columns and beams, one row just inside the original window line and the second on the new showcase line. Secondary beams then cantilever out to support the overhangs of the frontage at each level. The beams occur above the floor levels in most cases and the floor timbers are ‘hung’ from the new framework so that the cantilevers are not apparent on the external elevations. Cross-bracing was provided to resist full wind load in the post-demolition, prebuilding stage and beams were inserted at the future main floor levels between the rear row of columns to tie in the new concrete framework.

Site works

A strong scaffold was erected at the front of the façade to give additional support to the works and provide a· working platform for the renovation.

A trial pit had been dug in the region of the frontage during the initial investigations in order to determine the substrata, however, during the more extensive excavations for the foundations, it was clear that much of the ground beneath the C&A frontage was filled, and excavations for the front bases had in some cases to be taken down to 14 feet to find a suitable bearing stratum. Since careful shoring was necessary, the construction of the foundations became a very slow process.

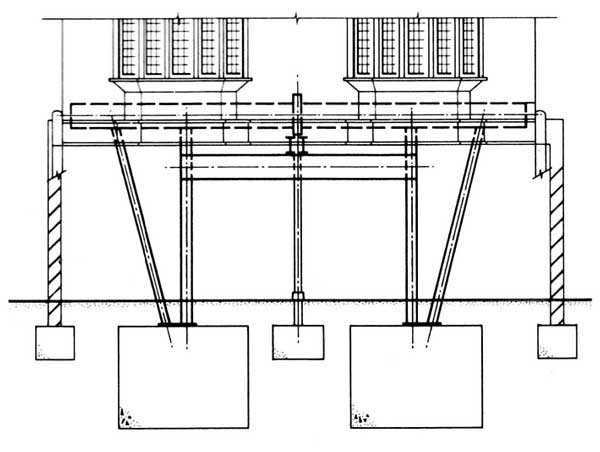

The existing C&A portion of the frontage was supported at the centre by a cast-iron stanchion carrying a pair of wrought-iron bressemers which spanned from the front of the building to a massive brick wall, 20 feet back, and which seemed to mark the extremity of the original building. This iron-work together with several other spans found in the first floor were presumably a relatively recent alteration in order to create an open area at ground floor suitable for shop use. Since this stanchion and its pad base obstructed the foundations for the outer row of columns, a system was devised to erect the front row of columns in stages, employing two temporary diagonal columns. This method is indicated in Fig. 2. A similar procedure was also adopted for the Austin Reed section.

Two concrete bases were constructed. two steel columns. and two temporary steel raking supports erected to support the main steel beam. which was installed behind the existing shop front. Twin temporary beams were then attached to the steel columns to support the existing bressemers; the existing cast-iron centre stanchion and base being then removed.

A central column and base were constructed, and the new centre column was welded to the existing iron bressemers. The erection of the steel framework was completed above first-floor level and the existing timber façade braced to it; the façade now being fully supported by the steel framework within. The old brickwork flank-walls and their foundations were removed.

Finally. the two end bases were constructed and the two end columns bolted up to the main beam; after which the temporary raking supports were removed.

The steel columns at street level were later clad with timber to match the existing woodwork.

The estimated progress in foundations and steelwork erection was not attained and with demolition proceeding at a rapid rate to the rear of the site, temporary dead shores were erected inside the old buildings and connected to the outer scaffold through the windows. Demolition had to stop short of the proposed line in order that the permanent shoring work could continue into the main contract period. During erection, the existing main floor members were cramped to the new framework. It had been intended to retain the front wall by letting 4in × 4in MS plates into the outside of the wall and bolting these through to channels fixed to the extremities of the cantilever beams. The plates and bolts would have been disguised by a timber cover or render, where they occurred on the front panelling. However, the fabric of the outer wall was in such poor condition, through rot and insect attack, that it was agreed to insert continuous bands of 3in × ¼in mild steel strip on each horizontal timber line. These were galvanized and painted black so they are not noticeable, and they are held back at approximately 3ft centres to a timber framework, built on the line of the front row of columns and in turn firmly attached to the steelwork (Fig 3).

As the main works progressed, the old buildings were demolished to the line of the proposed showcase windows and the new concrete structure was tied into the steelwork by encasing the rear line of columns and beams, giving in addition the necessary two-hours fire resistance. A fire wall was also built to isolate the potential fire risk of the old timber fabric.

The final structural operations were to remove the flank walls from the ground to first floor in order to create a pedestrian area at ground-floor level. What remained of the walls above first-floor level was pinned up from the steel framework.

The works were commenced at the end of February 1971 and the structural steelwork and tying back were completed by mid-May. Renovation and redecoration of the façades, which was started towards the end of this period, was completed by mid October. The structural work took longer than was programmed, but, due to unexpected ground conditions in the main structure, work to the frontages was not critical, and the time lost in the early stages was recovered to enable the building as a whole to finish on programme.

Finishes and preservative treatments

The Architect carried out a thorough inspection of both façades and the Main Contractor cut out and replaced all defective timbers, flashings and Wet Dash panels. When this was completed further inspections and discussion took place to decide how best the renovated work could be decorated to blend in with the original structure that remained. The C&A frontage was basically an oak structure with Wet Dash infill panels whilst the Austin Reed structure was of complete timber construction finished with various coloured gloss paints. The aim was to reproduce the original as closely as possible and to retain the character of the fronts that had evolved from age and exposure to the elements.

The C&A façade was treated as follows:

(a) All existing and new oak toned down to match and treated with three coats of Black Solignum.

(b) The Wet Dash panels coated with stabilizing liquid and painted three coats of Walpamur ‘Stronghold’ white emulsion.

(c) New oak cladding to the steel columns forming the colonnade treated with three coats of ‘Sadolins· PX 65 ebony wood preservative.

The Austin Reed frontage was cleaned down and repainted to match the original. The Architects were able to obtain an original colour print of this façade which was used by the Contractor as his colour guide.

An interesting feature on this frontage was the need to renovate and repaint the coat of arms and twelve crafts shields at first-floor level. The original colours had been completely destroyed and help was sought from the City’s Reference Library to trace the origins of these and thereby reproduce them in their true heraldic colours.

This work was carried out by Messrs M. T. Sleeman of Exeter, and it is due to the skill of their craftsmen that finally an almost identical reproduction was achieved.