50 & 20 Years Ago

Cased at ground level

Money has been saved and construction time reduced on this new recreation centre at Burnley by casing the beams on the ground. Mr. H. Westbrook, a director of Newtown Engineering Co. Ltd, steelwork contractors, describes the building and the use of this new technique.

This new sports and recreation complex is now being built for the Burnley Corporation and is in the centre of the town along Centenary Way. The facilities being provided will fulfill a long-felt need and it is pleasant to be able to record that the centre has been funded largely by a single local benefactor, while the balance has been found by the Corporation.

The accommodation includes a 12m bay for squash courts, a central bay of 2 spans of 18m for the sports halls with one span of 4·5m for the spectators’ gallery and a further side bay with a swimming pool of 18m span again with a spectators’ gallery of 4·5m span; the total width is therefore 75m, while the length is 58m. The roof heights are 7·85m for the squash courts, 14·85m for the sports halls and 8·40m for the swimming pool. The consulting engineers examined alternative materials of construction when preparing their designs and steel was chosen for a number of reasons, one of which was that as the building was sited over old mine workings there was a possibility of local settlement, for which condition the steel frame could provide the necessary degree of flexibility.

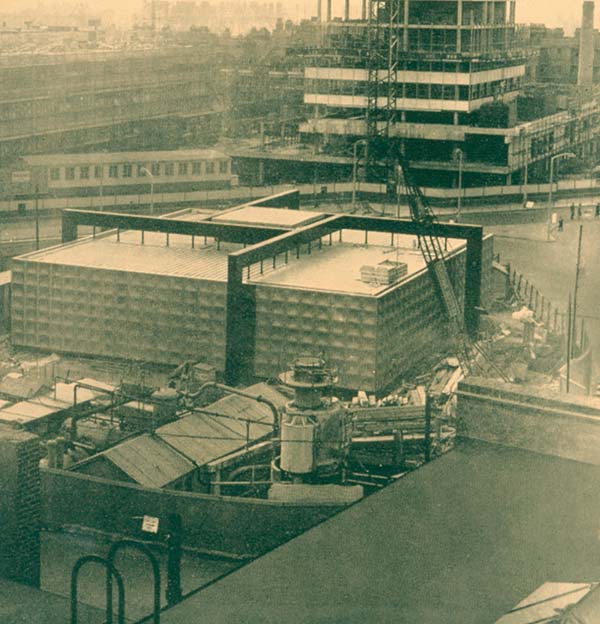

For their intended functions it is not necessary to provide fire protection to the steelwork for all the areas. However, there was a substantial number of beams and columns where some protection was required and it was decided that this should be concrete. The usual practice for casing steelwork is to first erect the frame and then pour the concrete in situ. For this contract a different method was adopted and most of the casing was poured at ground level, the steel component not being fixed into position until the concrete had set. In order to facilitate making connections, the ends of components were left bare and the small amount of extra concrete was then placed in situ.

The main reason for employing this method was to reduce to the minimum the time taken to clothe the building completely. The main contractors were anxious to obtain a dry working environment within the building before the end of the summer and casing at ground level made a significant reduction to the time required.

This method of providing the necessary fire protection was not part of the original contract, but the steelwork contractors accepted it willingly provided that they were allowed to add an extra two weeks to their erection programme and that they could make an additional charge to cover the extra work that would be required of them. Agreement was reached on these points as there would still be an economic advantage.

Approximately 400 beams were treated in this way and the weight of concrete per beam varied between ¾ ton and 3 tons. Altogether, the contract included about 470 tons of structural steelwork with around 450 tons of concrete casing. Four beams are 33in or 36in deep when cased, and it was found that they would have been too heavy to lift with the travelling jib crane being used. It was therefore decided that these should be cased by traditional methods, rather than bringing to the site another crane which would probably have seriously reduced the economic advantage.

Amongst the other advantages was the saving in scaffolding. The original programme called for conventional scaffolding to the framework in order to fix the shutterings and pour the concrete, but with this requirement almost entirely eliminated the only scaffold found to be necessary was an 8ft square staging at each stanchion.

In order to maintain the same programme of erection of the frame, the steel components had to be delivered to site two weeks in advance of the original date in order to provide enough time for pouring and casing. A large area had to be provided at site for the beams during casing, but fortunately ample space was available at Centenary Way. However, this requirement might prevent the adoption of the method on very congested sites.

The roof steelwork over the sports halls consists of lattice girders built up from structural hollow sections. With RHS chords and CHS bracings the fabrication proved to be particularly simple. All steelwork not encased in concrete was shot blasted and given one coat of priming paint. Floors to the spectators’ galleries and the plant room are concrete, while the suspended floors to the sports halls are timber.

All the framework is now completed and the building is well on the way to being fitted out on schedule despite the effect of labour disputes which, as on so many sites last year, stopped operations during the most potentially productive period.

The experiment has paid off and all concerned are convinced that, given the right circumstances, similar methods of construction will again prove of economic benefit.