Projects and Features

An introduction to section bending

Section bending was used extensively on Slough’s iconic Curve

Bending steel sections to help create stunning architectural designs not only allows steelwork to show its flexibility in construction, the process is also very economical.

Section bending is a cost-effective way of changing the shape of a structure, as it is relatively inexpensive when compared to manufacturing a multi-faceted member. In this article NSC will focus on section bending; the process, metallurgy of curving steel and minimum radii and tolerances.

The metallurgy of curving steel

The process of cold bending takes the material past its yield point and this strain will harden the steel to some degree. Some of the yield plateau has to be used, so in general plastic design is not recommended.

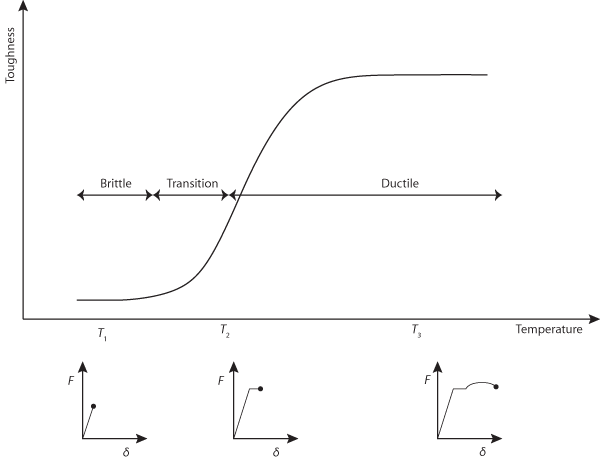

The toughness of the steel can also change particularly at small radii, but for most radii found in structural applications the changes are modest.

Schematic stress-strain diagram illustrating the effect of roller bending

For structural steel, the strain induced during the bending process produces no real problems, as afterwards the material exhibits the same elastic characteristics in the elastic range.

As mentioned, during the rolling bending process the material must be subjected to a stress greater than its yield strength or elastic limit, shown as point ‘A’ on the figure below. This is the maximum stress that the material can withstand and still spring back, or return to its original shape.

A stress less than the yield strength will not permanently bend the material. The amount of stress to apply to the material being bent is in area ‘C’, which is the plastic region. The spring back lines show how, when the stress is removed, the material will spring back to a curvature somewhat smaller than when the stress was being applied.

The steel sections become work hardened when using the cold bending process. The amount of work hardening is dependent on the radius required and the geometry of the section. This results in a ‘flattened-out’ stress-strain curve. A tensile test on a sample of steel that has been cold-roller bent will show a small loss in ductility, but a higher ultimate tensile strength. Even though there is a loss of some ductility, for normal structural applications the effect is minimal and can be ignored.

Minimum radii and tolerances

The minimum radius to which a section can be bent without any meaningful local distortion depends on the section properties and bending methods being used. These minimum radii have been reduced as new techniques have been developed, so the minimum has continued to get smaller.

Normal bending tolerances for single radius bends are in line with those specified in the National Structural Steelwork Specification. For tolerances for multi-radius bends or other complex curves it is best these are discussed with a specialist steel bender.

It is not easy to provide a definitive and comprehensive list of the radii to which every section can be curved. There are large numbers of standard sections (each with different bending characteristics), there are different methods of bending (hot and cold), and the end uses vary widely. Also, with continuing technical developments minimum radii also change.

In general, sections, tubes and hollow sections can be curved to single radius curves, to multi-radius curves, to parabolic or elliptical curves, or even to co-ordinates. They can also be curved in two planes or to form spirals. There are, however, a number of physical constraints which limits the degree to which three-dimensional curvature is possible in practical terms.

Sponsors

Sponsors

Steel Bending

Bronze: Barnshaw Section Benders Limited

Thanks to Barnshaw Section Benders Limited for contributing to this article.