Technical

AD 426: Bolt head protrusion through nuts and threads in grip lengths

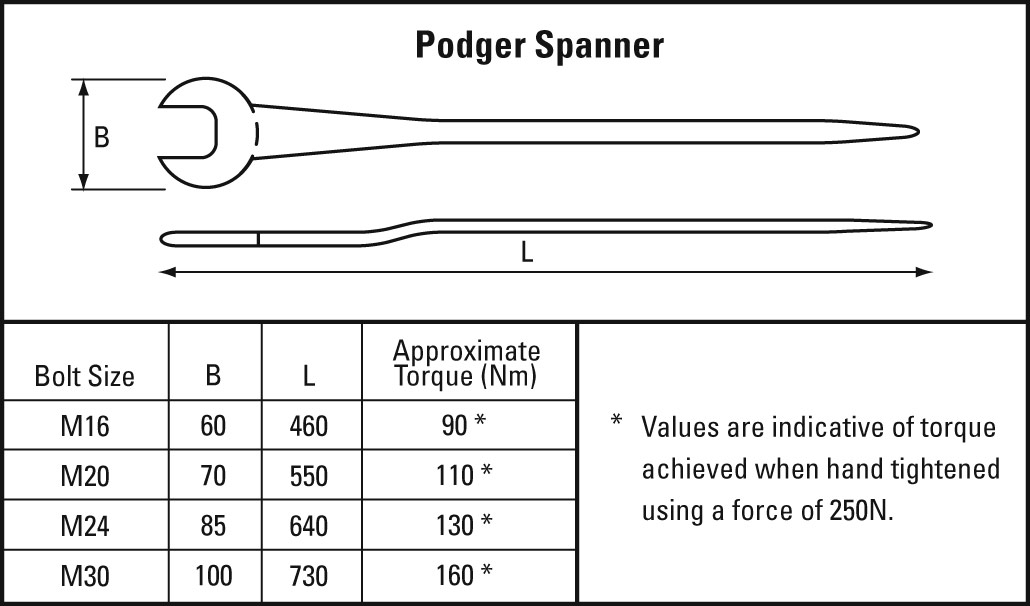

To ensure that bolt threads are fully engaged in the nut, BS EN 1090-2 clause 8.2.2 specifies that the protrusion must be at least one thread pitch. This is because the very end of the bolt may be slightly convex, leading to a reduced resistance if threads are not fully effective.

The same clause specifies the necessary numbers of threads within the grip length (between bolt head and the nut). For non-preloaded bolts, one full thread is required – to ensure the nut can be properly tightened. For preloaded bolts according to BS EN 14399-3 (HR system, generally used in the UK in preference to the HV system) or according to BS EN 14399-10 (HRC system, commonly known as a ‘tension control bolt’), a minimum of four threads within the tensioned length is specified. The reason for the threads in the tensioned length is to encourage ductile behaviour – AD 268 (which related to the BS 5950 requirements) reproduces a figure from Owens and Cheal (Butterworths), showing significantly more elongation when there are more threads in the tensioned length. Incidentally, BS 5950-2 required three and five threads in the tensioned length, for class 8.8 and 10.9 bolts respectively.

Contact: Richard Henderson

Tel: 01344 636525

Email: advisory@steel-sci.com