Technical

AD 342: Stainless steel fasteners

The purpose of this Advisory Desk Note is to provide guidance on the specification and selection of stainless steel fasteners for use in non-preloaded structural connections. The requirements for chemical composition and mechanical properties of stainless steel fasteners are specified in BS EN ISO 3506 Mechanical properties of corrosion-resistant stainless steel fasteners. The Standard was revised at the end of 2009 and now comprises four separate Parts: BS EN ISO 3506-1 covers bolts, screws and studs; BS EN ISO 3506-2 covers nuts; BS EN ISO 3506-3 covers set-screws; and BS EN ISO 3506-4 covers self-tapping screws.

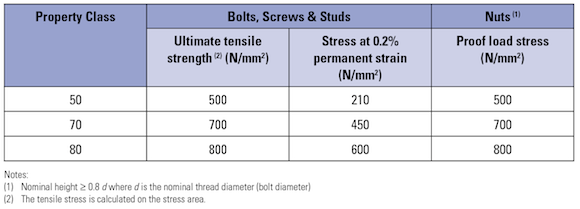

In this Standard, bolts, screws and studs are designated by a letter followed by three numbers, e.g. A2-70 or A4-80. The letter refers to the group of stainless steel: austenitic (A), martensitic (C) or ferritic (F). The letter is followed by a number (1, 2, 3, 4 or 5) which reflects the corrosion resistance; 1 representing the least durable and 5 the most durable. The final two numbers denote the property class, which describes the mechanical properties of the bolt, screw, stud or nut (see Table 1).

For most structural applications, it is generally recommended that austenitic bolts grade A2 or A4 and property class 70 or 80 are used. Steels of grade A2 have equivalent corrosion resistance to grade 1.4301 (304). Steels of grade A4 contain molybdenum and have equivalent corrosion resistance to grade 1.4401 (316). Property class 70 fasteners are made from cold drawn bar. Property class 80 fasteners are made from severely hard cold drawn bar, with mechanical properties similar to carbon steel and alloy steel grade 8.8 steel bolts to BS EN ISO 898.

The following alternatives may be considered for particular applications:

- A duplex composition (designated FA which stands for ferritic-austentic) is mentioned in Annex B of BS EN ISO 3506-1 and it is likely that this group of stainless steels will be included in future revisions of the Standard.

- Steel grade A1 is suitable for machining. Due to high sulfur content, the steels within this grade have lower resistance to corrosion than corresponding steels with normal sulfur content. Care should be exercised if Grade A1 bolts are being considered.

- The less common grades A3 and A5 are stabilised versions of A2 and A4 respectively and can be used as alternatives to A2 or A4 in applications where there is a risk of intergranular corrosion.

- Low carbon variants can be specified for A2 and A4 fasteners (e.g. A4L) with improved resistance to intergranular corrosion, particularly when welded (they are rarely used in practice).

- Property class 50 represents steel in the annealed condition and will be non-magnetic (unlike property classes 70 and 80, which may demonstrate some magnetic properties). If class 50 fasteners are specified with machined threads, they may be more prone to thread galling than those in the higher property classes.

- Although not included in the Standard, property class 100 bolts and nuts are available up to size M20 (stress at 0.2% permanent strain = 800 N/mm² and ultimate tensile strength = 1000 N/mm²).

- Additionally, duplex bolts and nuts are available in grade 1.4462 with mechanical properties in accordance with property class 80 and superior corrosion resistance to austenitic fasteners.

When choosing a stainless steel fastener, consideration should be given to matching the strength and corrosion resistance of the bolts and parent material. To avoid the risk of bimetallic corrosion (see Advisory Desk 339), stainless steel bolts should always be used when connecting stainless steel members. Stainless steel bolts are also suitable for connecting galvanized steel and aluminium members.

Expressions for shear, tension and bearing resistances of stainless steel fasteners are given in:

Design Manual for Structural Stainless Steel, Third Edition, Euro Inox and SCI, 2006

Available from www.euro-inox.org or www.steel-stainless.org/designmanual

Structural Design of Stainless Steel, P291, 2001

Available from www.steelbiz.org. Paper copies may be ordered from Steelbiz or directly from SCI.

Guidance on the grade of fasteners to use in swimming pool environments is available on the BSSA web site (www.bssa.org.uk).

The above guidance includes information provided by Stainless Steel Fasteners Ltd (www.ssfast.co.uk).

Contact: N R Baddoo

Tel: 01344 636525

Email: advisory@steel-sci.com