Technical

Advances in structural applications of stainless steel

Stainless steel is suitable for a wide range of structural elements where strength, ductility, durability, appearance and low maintenance are required. SCI’s Nancy Baddoo describes some new developments in structural applications of stainless steel.

Applications using duplex stainless steel grades

Structural applications of stainless steel have generally used austenitic grades: types 1.4301/1.4307 for rural, urban or lightly industrial environments and types 1.4401/1.4404 for heavily industrial or marine environments. The use of duplex stainless steels is relatively new to the construction industry although they have a long track record in the petrochemical and pulp and paper industries. These alloys have high strength (design strengths around 450 N/mm²) and ductility (>20%) with good weldability and formability. They have tremendous potential for expanding future structural design possibilities, enabling a reduction in section size and leading to lighter structures. A range of open and closed structural profiles are available in duplex grades. Design guidance can be found in the Design Manual for Structural Stainless Steel [1] and updated guidance on fabrication has just been published [2].

Figure 3: Installation of stainless steel accommodation modules on the Armada Platform (Photo: Mech-Tool Engineering)

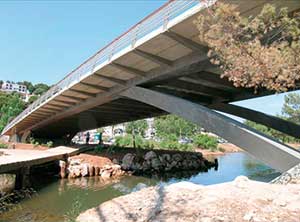

Duplex grade 1.4362 was used for the arches of the Celtic Gateway footbridge in Holyhead, Wales, which was opened in 2006. This grade has a corrosion resistance similar to that of austenitic grade 1.4401 and twice the design strength. The more highly alloyed duplex grade 1.4462 was used for the arch of the Millennium Bridge in York and the first stainless steel road bridge, built in Menorca in 2005 (Figure 1). This grade displays superior corrosion resistance, especially to stress corrosion cracking.

High nickel prices have more recently led to a demand for ‘lean’ duplexes with very low nickel content, such as grade 1.4162. The corrosion resistance of grade 1.4162 lies between that of 1.4301/1.4307 and 1.4401/1.4404. Due to its low nickel content of 1.5% (typical stainless steels have >3%), it is an economical alternative to other austenitic and duplex grades whilst also experiencing lower price volatility. One of the earliest structural applications of this grade was a footbridge with a 120 year design life in the suburb of Ruffolo, Siena in Tuscany. The cable stayed bridge spans 60m over a busy motorway and was completed in 2006 (Figure 2). Lean duplex 1.4162 was used for the pylons and load carrying longitudinal and transverse beams.

Exploiting the distinctive properties of stainless steel

The structural performance of stainless steel differs from carbon steel because stainless steel has no definite yield point and shows an early departure from linear elastic behaviour with strong strain hardening. The shape of the stress-strain curve in the plastic range ensures higher plastic moment resistance than carbon steel of equivalent strength. Stainless steel is therefore an ideal material for explosion-resistant structures because it has high strength, good energy absorption characteristics and high ductility. An additional advantage when considering blast resistance is that the strain-rate sensitivity is more pronounced in stainless steels than in carbon steels with a proportionally greater strength realised at fast strain rates for stainless steel than for carbon steel, particularly in the region of the 0.2% proof strain.

The strength and stiffness retention characteristics of stainless steel at elevated temperatures also differ from carbon steel. Austenitic stainless steels show superior strength retention properties above temperatures of around 550°C and superior stiffness retention at all temperatures. Retention factors for the key grades of stainless steel are reported in the Design Manual for Structural Stainless Steel [1].

The combination of resistance to fire and blast coupled with exceptional durability has led to many structural applications in the oil and gas industry. Stainless steel grade 1.4401 was chosen for the fire and blast rated cladding for four new accommodation modules and two walkway modules installed earlier this year on BG Group’s Armada Platform in the Central North Sea. The cladding, formed from corrugated sheet 80mm deep and 2mm thick, is designed to resist blast pressures of 110 millibar.

Hot rolled and welded stainless steel sections

There is no standardised family of sizes for stainless steel structural sections. Hollow sections are available in a wide range of sizes, with each manufacturer tending to stock its own range. Channels and angles tend to be produced by roll forming (rolling or bending) and are frequently made to order. The availability of hot rolled and laser welded I sections is increasing.

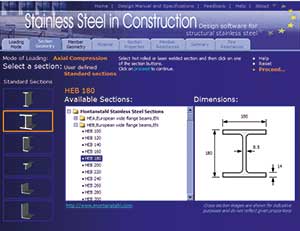

In 2003, SCI developed web-based design software for cold-formed stainless steel members such as hollow sections, channels and equal angles (available on www.steel-stainless.org/software). The software calculates section properties and member resistances for user-defined sections. It aligns to the Eurocode for structural stainless steel [3] and includes a fire resistance design facility that estimates how quickly a section will heat up in standardised fire situations and its reduced resistance after exposure to the fire.

With sponsorship from the Swiss section manufacturer Montanstahl, the design facility has now been extended to cover a range of laser fused and hot rolled structural sections (I sections, T sections, equal and unequal angles). Additionally, an online section database has been incorporated so that users can select a particular section from the Montanstahl range for use in the design software (Figure 4). It is intended that the database will be extended further to include sections from other manufacturers.

Although a US specification dealing with the structural design of cold formed light gauge stainless steel has been available for many years, there is no US design standard covering heavier sections in stainless steel. Work is underway at SCI on an AISC Design Guide for hot rolled and welded stainless steel structural sections. The guidance will be in accordance with US philosophy and aligned to the principles of the AISC Steel Construction Manual. It is hoped that the availability of this design guidance will facilitate greater and more efficient use of hot rolled and welded steel in the US, and other countries such as China which use US design standards.

Model specification for fabrication and erection

Unintended over-specification by the designer, such as requiring an architectural surface finish for a structural component where visual appearance is not important, can lead to unduly high fabrication and installation costs for stainless steel fabrications. To overcome this problem, SCI are working with Arup to prepare a model specification for structural stainless steel which aids the specification of appropriate standards for surface finish, joining, fabrication, erection, installation, inspection, maintenance and cleaning. The scope of the specification will be limited to building construction, although further versions could cover other forms of construction such as bridges. The specification will align to the new European fabrication and erection specification EN 1090-2 [4].

Use of a stainless steel model specification will lead to greater uniformity in structural steelwork contract specification, and thus help to achieve more cost effective stainless steel structures. The specification will be prepared in such a way that it is suitable for incorporation within the forms of contract normally employed in the steel construction industry. It will be available as a downloadable Word file so that specifiers can customise it to suit their particular project requirements.

References

- [1] Design Manual for Structural Stainless Steel (with design examples and a background commentary, available in seven languages), Euro Inox and The Steel Construction Institute, Third Edition, 2006 www.steel-stainless.org/designmanual

- [2] Practical Guidelines for the Fabrication of Duplex Stainless Steels, International Molybdenum Association, 2009

- [3] EN 1993-1-4:2006 Eurocode 3. Design of steel structures. General rules. Supplementary rules for stainless steels

- [4] EN 1090-2:2008 Execution of steel structures and aluminium structures. Technical requirements for the execution of steel structures