Projects and Features

A guide to steel production equipment

Steel manufacturing equipment and its producers play an essential role within the structural steelwork sector.

Steel manufacturing equipment is extensively used in steelwork contractors’ workshops and has also become part of the added value offer from larger steel stockholders who are offering basic fabrication services to their customers.

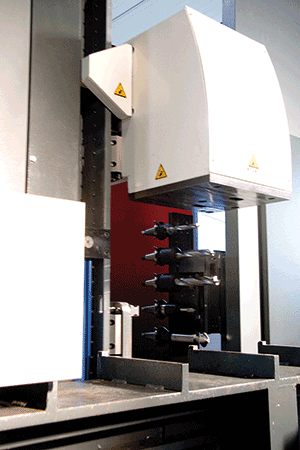

Cutting and drilling

In the fabrication factory or steel service centre one of the first operations is to cut the sections to length and profile the plates to the desired size or shape. This can be done in a number of ways using a range of automated machinery; Band saws which are generally used for cutting to length, oxy/gas cutting which can be used to cut components from thick steel plate; components can also be cut efficiently by plasma arc systems. To support the efficiency of the steelwork fabrication process the use of drilling and punching equipment allows components to be rapidly bolted together on site.

Blast cleaning and auto-painting

For many steelwork contractors, sections and plates are blast cleaned prior to fabrication, although some choose to carry out the blast cleaning after the sections are cut to length. Shot is fired at the steel surface which displaces dirt and mill scale, and also mildly indents the steel creating a “rough” surface. Manufacturing equipment with auto-painting functions mean that prefabrication primers can be applied immediately after blast cleaning. This immediate application maintains the reactive blast cleaned surface in a rust-free condition through the fabrication process until final painting can be undertaken.

Multi-function machinery and workshop design

Equipment manufacturers are increasingly offering multi-function machines which combine a number of the processes outlined above. In addition to offering multi-function machinery, manufacturers of steel fabrication equipment work closely with steelwork contractors planning the workshop design and layout with real time simulation to find the best flow of materials and maximise production based on required output through the use of advanced simulation software.

Computer Numerically Controlled machinery

Advanced simulation software has established Computer Numerically Controlled (CNC) machinery as the standard today and it is integrated into each stage of the steel fabrication process. The process may vary between each steelwork contractor but will generally commence with the efficient and seamless transfer of 3D model information from the design office to the equipment in the workshop.

CNC machinery provides a number of added value benefits to the steelwork contractor including; less material wastage due to accuracy, faster production and increased safety through reducing material handling.

The structural steelwork sector is also seeing the adoption of modern scribe marking technologies. This software allows for full or partial contours to be scribed directly onto the steel to indicate the position of the parts that need to be welded, saving valuable time and minimising errors. In addition, information can be marked on the steel indicating quality, traceability, welding information and assembly details.

“Improvement in CNC technology and automation has been a priority for Ficep, many customers have seen the advantage of automating even a single machine in a workshop. Customers involved with steel processing have been given a boost in productivity and competitiveness to levels that we have never seen before,” says Ficep Managing Director Mark Jones.

Post-sale support

The role of the manufacturing equipment providers doesn’t end with the sale of the machinery. Once a customer has invested in a new machine or processing line, they want to be sure it works and continues to work properly.

In addition to the standard warranty which comes with any new piece of machinery, manufacturers also offer a range of service support contracts.

Remote diagnostics is now integral as it allows technicians and service engineers to repair equipment without visiting the customer; saving time and meaning repairs are executed faster.

The Future

The sector is moving towards the adoption of full automation of all processes on the factory floor, utilising robots or cobots (collaborative robots) where humans and robots work together with direct interaction in a defined workspace to reduce material handling and welding. While this is some way off, some steelwork contractors are already moving into robotics.

‘In a world that is evolving at a faster pace than ever, Peddinghaus manufactures machinery that withstands the test of time. Integrating flawlessly with industry leading software companies our steel fabrication equipment is innovative, powerful, indestructible and backed by our 24/7 customer service department,” sums up Anton Peddinghaus, CEO of Peddinghaus Corporation.

Sponsors

Sponsors

Manufacturing equipment

Gold: Ficep UK Ltd, Peddinghaus Corporation

Bronze: Kaltenbach Ltd, Voortman Steel Machinery